Understanding Industry Standards in Best Small Part Machining for Global Buyers

In today's competitive manufacturing landscape, understanding industry standards is crucial for global buyers seeking excellence in small part machining. With the global small part machining market projected to reach $5.8 billion by 2025, according to a recent market analysis report, the demand for precision machined components continues to rise across various sectors, including automotive, aerospace, and medical devices.

As companies expand their operations internationally, navigating import and export certifications becomes essential to ensure compliance and quality assurance. These certifications not only signify adherence to stringent manufacturing standards but also enhance the credibility of suppliers in the global marketplace. By grasping the intricacies of these industry standards, buyers can make informed decisions, fostering trust and securing high-quality small part machining services that meet their specific requirements.

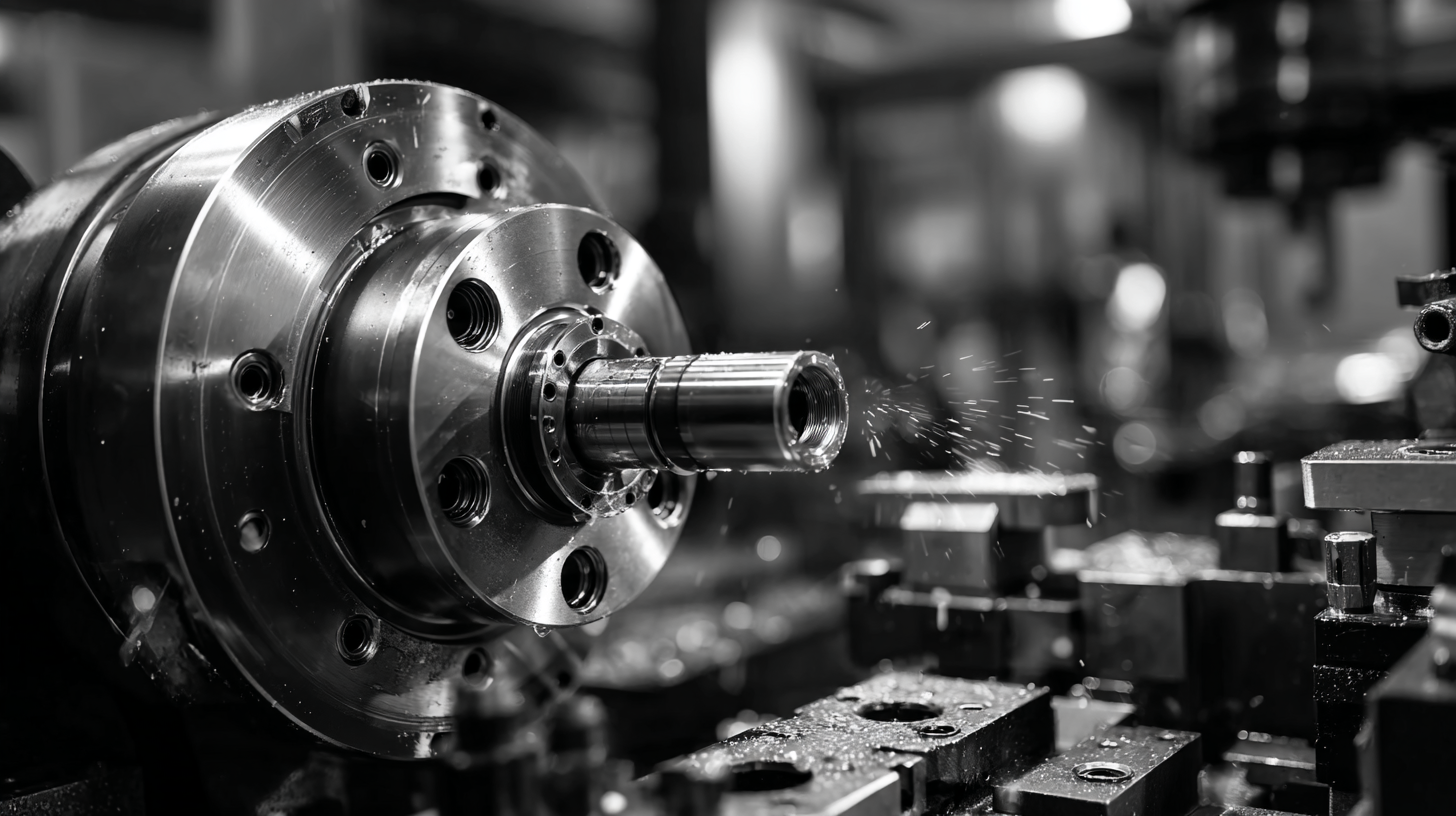

Understanding the Importance of Precision in Small Part Machining for Global Markets

In the realm of small part machining, precision is paramount, especially for global markets where the demand for high-quality components continues to rise. Precision in machining not only ensures that parts fit together seamlessly but also plays a critical role in the performance of the final product. For buyers sourcing components from different regions, understanding the nuances of precision standards is essential. This includes familiarity with the tolerances that various industries require, which can vary significantly depending on application—be it aerospace, automotive, or electronics.

Moreover, the importance of adhering to industry standards cannot be overstated. Consistent precision leads to reduced waste and rework, ultimately saving costs and time for manufacturers and their customers. Global buyers must engage with suppliers who prioritize quality control and have robust machining processes in place. As they navigate various suppliers, a commitment to precision will not only enhance product reliability but also bolster the overall reputation of their brand in competitive markets. In a landscape where the stakes are high, investing in precision small part machining proves to be a foundational element for success.

Key Industry Standards: Ensuring Quality and Consistency in Machining Processes

In the world of small part machining, adherence to industry standards is crucial for ensuring quality and consistency. These standards not only guide manufacturers in achieving precision but also help buyers to make informed decisions when selecting suppliers. To maintain high-quality outputs, it’s essential that machining processes comply with relevant standards such as ISO 9001, which focuses on quality management systems, and others that specify tolerances and surface finishes.

Tip: When assessing potential suppliers, always inquire about their certifications and quality assurance practices. This ensures that they meet recognized standards, minimizing the risk of defects in the final product.

Moreover, consistency in machining processes enhances not just product quality but also overall operational efficiency. Standardized processes allow for easier training and reduce variability in production. For global buyers, understanding these standards can streamline communication and expectations with manufacturers across different regions.

Tip: Consider conducting regular audits of your machining partners to verify compliance with industry standards. This proactive approach can help catch issues before they affect production, ensuring that your supply chain remains reliable and efficient.

Understanding Industry Standards in Best Small Part Machining for Global Buyers

| Standard Name | Description | Industry Application | Importance |

|---|---|---|---|

| ISO 9001 | Quality management systems - Requirements | Manufacturing, Service Providers | Ensures consistent product quality |

| AS9100 | Quality management system for aerospace | Aerospace Industry | Critical for safety and reliability |

| ISO/TS 16949 | Quality management standard for automotive | Automotive Industry | Improves product quality and reduces waste |

| IEC 60601 | Medical electrical equipment safety standards | Medical Devices | Ensures safety of medical devices |

| ISO 13485 | Quality management systems for medical devices | Medical Device Manufacturing | Enhances compliance for medical products |

Analyzing the Competitive Advantages of Chinese Manufacturing in Small Part Production

Chinese manufacturing has established a competitive edge in small part production, driven by a combination of advanced technology adoption and cost efficiencies. The country is at the forefront of a new phase of industrialization, characterized by investments in automation and high-tech machinery. This approach enables Chinese manufacturers to not only meet the demands of global buyers but also to enhance their production standards significantly. As they navigate the pressures of overcapacity and trade dynamics, Chinese firms focus on innovation and efficiency, thereby solidifying their position as leaders in quality small part machining.

Chinese manufacturing has established a competitive edge in small part production, driven by a combination of advanced technology adoption and cost efficiencies. The country is at the forefront of a new phase of industrialization, characterized by investments in automation and high-tech machinery. This approach enables Chinese manufacturers to not only meet the demands of global buyers but also to enhance their production standards significantly. As they navigate the pressures of overcapacity and trade dynamics, Chinese firms focus on innovation and efficiency, thereby solidifying their position as leaders in quality small part machining.

Furthermore, the evolution of China’s manufacturing model is indicative of a broader strategy to climb the value chain amidst global competition. By integrating low-carbon technologies and embracing innovative practices, Chinese manufacturers are not only improving their operational performance but also responding to international sustainability standards. This adaptability makes them attractive partners for global buyers seeking reliable and compliant production capabilities. As such, the competitive advantages of Chinese small part manufacturers lie not solely in cost but also in their commitment to quality and innovation, which are increasingly critical in today's industrial landscape.

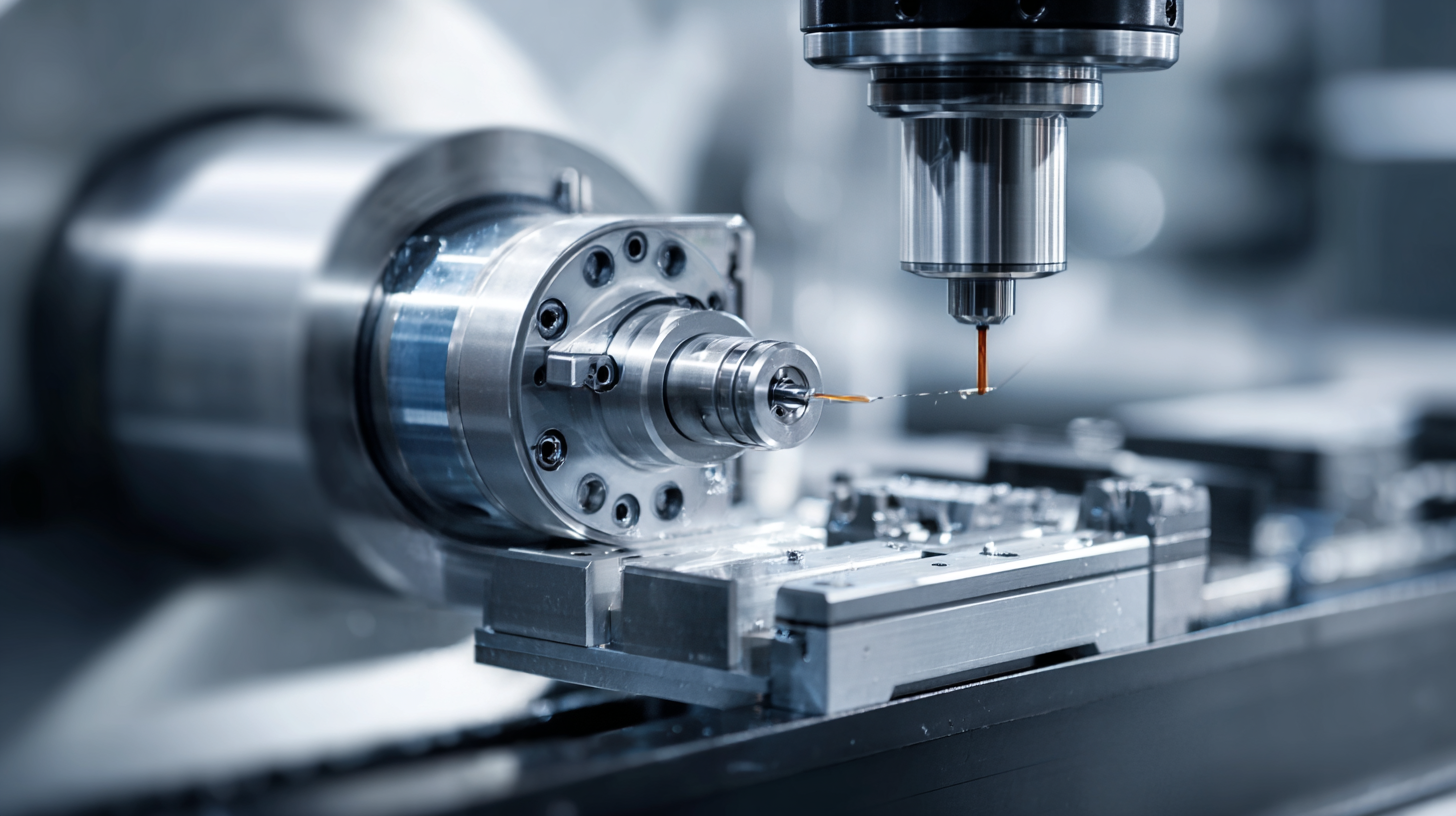

Technological Innovations Driving Efficiency in Small Part Machining

The advancements in technology have significantly transformed the small part machining industry, enabling manufacturers to achieve unparalleled efficiency and precision. Cutting-edge innovations such as computer numerical control (CNC) machining and automation are at the forefront of this transformation. CNC machines allow for intricate designs and repeatable accuracy, thereby reducing human error and increasing production speeds. As global buyers seek high-quality components, these technological advancements ensure that manufacturers can meet stringent industry standards while maintaining cost-effectiveness.

Additionally, the introduction of real-time data analytics and IoT (Internet of Things) integration into machining processes enhances operational efficiency. Manufacturers can monitor machinery performance and production metrics in real time, enabling them to make informed decisions that optimize resource allocation and minimize downtime. This data-driven approach not only improves the overall quality of small parts but also enhances traceability and compliance with international standards. Such innovations are essential for competitive positioning in the global market, as they bolster the ability to meet diverse customer needs swiftly and reliably.

Understanding Industry Standards in Best Small Part Machining

This chart illustrates the key industry standards in small part machining, highlighting the efficiency, quality, cost, innovation, and lead time as critical metrics driving the sector's performance.

Global Buyer Perspectives: Evaluating Reliability and Quality in Sourcing Small Parts from China

When sourcing small parts from China, global buyers often prioritize reliability and quality. A comprehensive survey conducted by the International Trade Administration indicates that over 65% of companies view quality assurance as their primary concern when collaborating with Chinese manufacturers. This highlights the necessity for buyers to establish stringent evaluation criteria to ensure that the parts meet international standards. With stringent adherence to ISO 9001 quality management practices, manufacturers in China can significantly mitigate risks associated with subpar production processes.

Moreover, recent data from the Boston Consulting Group reveals that 72% of buyers actively seek suppliers who implement rigorous quality control measures. This includes certifications such as CE marking and compliance with RoHS standards. Many successful companies are investing in supplier audits and establishing long-term relationships based on trust and mutual growth. By leveraging advanced technologies, such as AI and IoT, suppliers are enhancing transparency throughout the production cycle, further ensuring that global buyers receive components that not only meet specifications but also uphold reliability, ultimately fostering a competitive edge in the market.