Top 10 Fast CNC Machining Services Delivering Precision and Speed in 2023

In the fast-paced world of manufacturing, the demand for precision and speed is more critical than ever, particularly in the realm of fast CNC machining. According to a recent report by Smith & Associates, the market for CNC machining services is projected to grow at a compound annual growth rate (CAGR) of 6.4% from 2020 to 2025, underscoring the increasing reliance on advanced machining technologies. As industries across sectors seek to enhance productivity while maintaining quality, fast CNC machining has emerged as a cornerstone of competitive strategy.

Industry experts emphasize the necessity of rapid turnaround times without compromising precision. John D. Taylor, a respected authority in the field of CNC technology, has remarked, “In today's manufacturing landscape, the ability to deliver fast CNC machining solutions is not just a value-add; it is a fundamental requirement for sustainability and growth.” As we explore the top 10 fast CNC machining services of 2023, it becomes vital to recognize the companies that are not only keeping pace with technological advancements but are also setting the benchmark for excellence in manufacturing precision and efficiency.

With technological innovations and the escalation of consumer demands, the landscape of fast CNC machining continues to evolve. This exploration aims to identify the key players that stand out in delivering high-quality, rapid machining solutions that meet the rigorous standards of modern production environments.

The Rising Demand for Fast CNC Machining Services in 2023

The rising demand for fast CNC machining services in 2023 is largely driven by the need for rapid production and high precision across various sectors, including construction and automotive industries. As global markets evolve, industries are increasingly recognizing the importance of delivering products quickly while maintaining stringent quality standards. The projected growth in related markets, such as the rapid drying concrete market and the orthopedic contract manufacturing sector, demonstrates the expanding need for efficient machining services that ensure timely delivery.

Tips: When selecting a CNC machining service, consider looking for companies that utilize advanced technology, such as multi-axis machining centers. This helps in achieving more complex designs with greater accuracy in shorter time frames. Additionally, ensure that the service provider has a robust quality control process in place to maintain precision throughout production.

Investments in high-speed tools and precision equipment are crucial for meeting the demands of today's fast-paced market. Companies should also focus on continuous training for their workforce, especially in the realm of CNC programming and machine operation, to keep up with technological advancements and maintain competitiveness.

Key Features that Define Top Fast CNC Machining Services

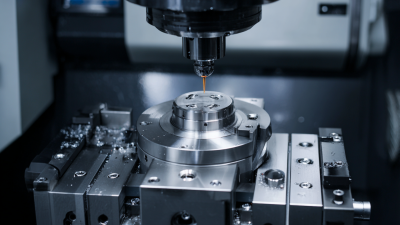

In 2023, the landscape of CNC machining services is defined by key features that emphasize both precision and speed. As the CNC machine market continues to grow, projected to reach $195.59 billion by 2032, the demand for rapid and high-quality machining services has never been more critical. Top providers understand the need for advanced capabilities, enabling engineers to accelerate both rapid prototyping and product development. This focus on automation and streamlined processes significantly enhances efficiency, allowing for quicker turnaround times without compromising quality.

Moreover, the ability to handle challenging materials with specialized cutting strategies illustrates the versatility and technical prowess of leading CNC machining services. Features like high precision in creating complex parts and the ability to produce lightweight components for various applications highlight the evolving needs in manufacturing. As businesses increasingly rely on these advanced machining services to stay competitive, the emphasis on delivering reliable, fast, and accurate results will continue to differentiate the top contenders in the industry.

Top 10 Fast CNC Machining Services Delivering Precision and Speed in 2023

| Service Type | Lead Time (Days) | Precision Level (µm) | Material Range | Prototyping Capability |

|---|---|---|---|---|

| CNC Milling | 3-5 | 0.01 | Aluminum, Steel, Plastic | Yes |

| CNC Turning | 4-6 | 0.02 | Brass, Stainless Steel | Yes |

| CNC Wire EDM | 5-7 | 0.005 | Titanium, Hard Metals | Yes |

| CNC Laser Cutting | 2-4 | 0.1 | Sheet Metal, Acrylic | Yes |

| CNC 5-Axis Machining | 7-10 | 0.01 | Aluminum, Steel, Titanium | Yes |

Impact of Precision on Product Quality and Customer Satisfaction

Precision in CNC machining plays a pivotal role in determining product quality. When manufacturing components, even the slightest deviation from specified tolerances can lead to functional impairments or product failures. High-precision CNC machining ensures that parts are produced to exact specifications, which minimizes waste and rework. This accuracy not only enhances the performance of the finished product but also extends its lifespan, thereby providing greater value to clients.

Precision in CNC machining plays a pivotal role in determining product quality. When manufacturing components, even the slightest deviation from specified tolerances can lead to functional impairments or product failures. High-precision CNC machining ensures that parts are produced to exact specifications, which minimizes waste and rework. This accuracy not only enhances the performance of the finished product but also extends its lifespan, thereby providing greater value to clients.

Moreover, the impact of precision extends beyond the product itself to customer satisfaction. In today's competitive market, customers are increasingly discerning, requiring high quality and reliability in the products they purchase. When manufacturers deliver precise components consistently, they foster trust and build long-term relationships with their customers. As a result, businesses that prioritize precision in their CNC machining processes tend to experience higher levels of customer satisfaction, repeat orders, and positive referrals, solidifying their standing in the marketplace.

Technological Advancements Driving Speed in CNC Machining

The adoption of new digital manufacturing technologies has revolutionized CNC machining, enhancing both precision and speed across various sectors. In 2023, the European CNC machine market is projected to witness substantial growth, driven by advancements in automation, artificial intelligence, and machine learning. According to recent market analysis, the CNC machine market in Europe is expected to reach significant milestones by 2033, with a CAGR of approximately 7.5%, showcasing the increasing demand for high-speed machining solutions.

In the context of technological advancements, the implementation of advanced software systems has streamlined operations, allowing for real-time monitoring and adjustments. This integration leads to drastically reduced lead times, enabling manufacturers to respond swiftly to market demands. Reports indicate that organizations adopting these latest technologies are experiencing productivity increases of up to 30%, emphasizing the critical role of innovation in maintaining competitive advantage in the fast-paced machining landscape. As industries continue to embrace digital transformation, the importance of efficient and precise CNC machining becomes ever more vital.

Top 10 Fast CNC Machining Services Delivering Precision and Speed in 2023

This bar chart illustrates the average lead time (in days) of the top 10 fast CNC machining services in 2023, showcasing the advancements in technology that contribute to increased speed and precision in the manufacturing process.

Comparative Analysis of Leading CNC Machining Service Providers

The CNC machining industry is witnessing significant growth, with a projected increase in the global CNC machine market size from $101.22 billion in 2025 to an impressive $195.59 billion by 2032, reflecting a compound annual growth rate (CAGR) of 9.9%. This surge is fueled by advancements in technology and the increasing demand for precision machining services across various sectors. Particularly in the medical industry, the precision machining service market for medical implants is anticipated to reach $1,964.5 million, growing at a CAGR of 6.4% over the next decade, indicating a robust need for high-quality CNC services that cater to specialized applications.

Moreover, the woodworking CNC tools market is also expanding, with a value of USD 8.2 billion in 2025 projected to rise to $13.4 billion by 2035, showcasing a CAGR of 5.0%. This growth is indicative of the rising trend in automated woodworking processes and the adoption of CNC technology in crafting bespoke wooden products. As companies prioritize efficiency, speed, and precision, a comparative analysis of leading CNC machining service providers reveals a competitive landscape poised to capitalize on these market dynamics. Understanding the strengths and offerings of these top service providers becomes essential for businesses looking to leverage CNC machining for their manufacturing needs.

Related Posts

-

Navigating the Future: How Best Rapid CNC Machining Will Shape Industry 2025 Trends

-

Maximizing Value: How Exceptional After-Sales Service and Low Repair Costs in Best Rapid CNC Machining Set You Apart

-

Unlocking Precision: How Fast CNC Machining Revolutionizes Manufacturing Efficiency by 30%+

-

5 Reasons Why Rapid CNC Machining is Your Best Option for Global Sourcing

-

Finding Top Quality Suppliers for Best Precision CNC Machining Solutions

-

7 Best Practices for Precision CNC Machining: Achieving 99.9% Accuracy in Manufacturing