Top Tips for Choosing a Wire Mesh Weaving Machine?

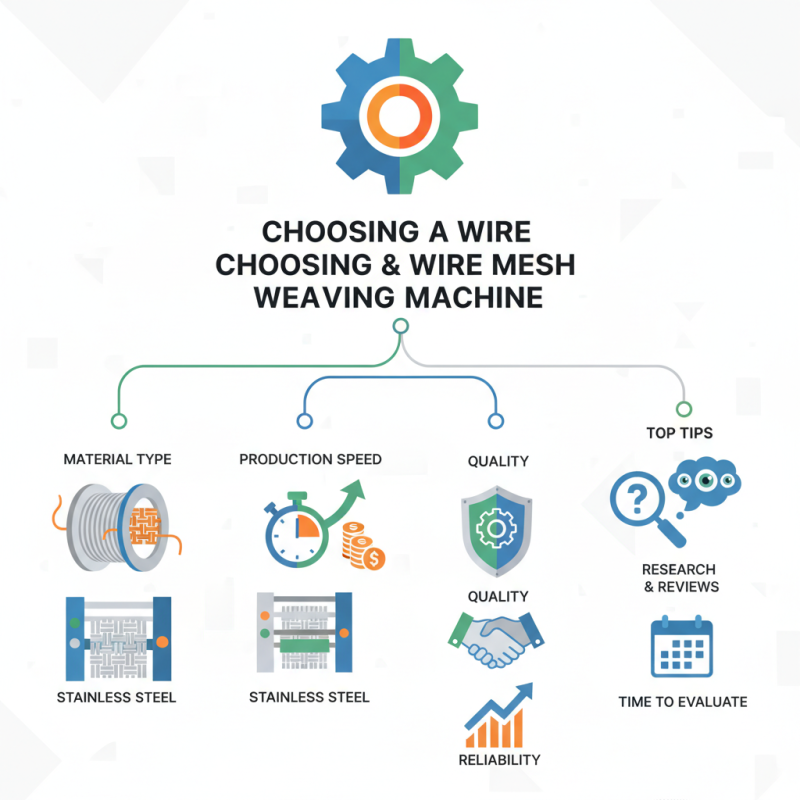

Choosing the right wire mesh weaving machine can be a daunting task. The market offers a variety of options, each with unique features. Understanding your specific needs is crucial.

Consider the material you intend to weave. Different machines work best with various wire types. For example, stainless steel may require a sturdier machine. Think about the production speed you need. A faster machine may boost productivity but could come with a higher price tag.

Quality is another key factor. Not all machines are built to last. Investing in a reliable wire mesh weaving machine may prevent future issues. Research user reviews and expert opinions. You may uncover details that aren’t obvious at first. Take your time to evaluate. The right choice can greatly impact your operations and profits.

Understanding the Different Types of Wire Mesh Weaving Machines

When selecting a wire mesh weaving machine, it's essential to understand the various types available. Different machines produce different mesh patterns and material structures. Some are designed for durability, while others focus on precision. Knowing these details helps in making an informed choice.

Consider your production needs. Evaluate if you require a machine for light-duty or heavy-duty projects. Light machines may weave simple patterns, while heavy-duty ones offer more complexity. This distinction impacts your projects significantly, so clarity on your needs is vital.

Tip: Always assess the machine’s speed and efficiency. A fast machine may improve productivity, but if it's not reliable, you might face issues. Sometimes, slower machines produce better quality mesh.

Another aspect to ponder is maintenance. Some machines require more upkeep. This can affect costs over time. A less reliable machine could lead to production downtime. Think about the long-term implications, not just the initial investment.

Top Tips for Choosing a Wire Mesh Weaving Machine

Key Features to Look for in a Wire Mesh Weaving Machine

When selecting a wire mesh weaving machine, consider its key features. The machine's speed is crucial. A faster machine increases productivity. Productivity is essential in competitive markets. Look for machines with adjustable weaving speeds. This flexibility allows you to adapt to different projects.

The type of control system is also important. A user-friendly interface simplifies operation. Programmable settings can enhance efficiency. Manufacturers often offer machines with varying degrees of automation. Fully automated models can save time but may require a larger investment. Reflect on your budget and needs before making a decision.

Material compatibility should not be overlooked. Different machines handle various wire types. Ensure the machine can weave the specific wire you plan to use. Additionally, consider the ease of maintenance. Machines that are difficult to repair can lead to downtime. Regular upkeep is essential for long-term performance. Evaluating these aspects carefully can lead to a better investment.

Assessing Production Capacity and Efficiency

When choosing a wire mesh weaving machine, production capacity and efficiency are vital factors. Evaluating your production needs is the first step. Consider the volume of mesh you plan to produce daily. This influences your choice of machine size and speed. If you understate your needs, you may face bottlenecks.

Efficiency plays a crucial role in profitability. A machine with high-speed capabilities may seem tempting. However, it’s important to ensure it doesn’t compromise on weave quality. Sometimes, slower machines provide better results, especially for intricate designs. Take time to assess the machine's features. Consider its ease of maintenance and operational costs too.

Quality and efficiency can sometimes conflict. A machine designed for higher output might not always yield a consistent product. Regular reflection on your production processes can highlight hidden inefficiencies. Striking a balance between speed and quality is essential for sustainable operations. Always analyze and adapt to improve your weaving capacity and output.

Evaluating Material Compatibility and Durability

When selecting a wire mesh weaving machine, material compatibility is vital. Different materials require specific weaving techniques. For instance, stainless steel needs robust machines due to its strength. On the other hand, softer materials like nylon can work with lighter equipment. Make sure to match the machine's capabilities with the materials you wish to use.

Durability is another key factor to consider. Machines are an investment, so assessing their longevity is essential. Look for machines that can withstand various production demands. Regular inspections can prevent unexpected breakdowns. Sometimes, people overlook minor wear. This can lead to larger issues in the long run, costing time and money.

Here are some tips: Always ask about the materials a machine can handle. Research the typical lifespan of similar machines. Don’t forget to consider the maintenance requirements. Machinery with complicated parts may require more frequent servicing. Simple designs might need less attention, but they should still be durable. It's essential to find a balance between complexity and ease of use.

Budget Considerations and Cost-Effectiveness Analysis

When it comes to choosing a wire mesh weaving machine, budget plays a critical role. According to a recent industry report, manufacturers often allocate 30% of their overall capital for machinery. This allocation must be balanced with the potential return on investment (ROI). A mid-range machine may cost $50,000 but can significantly increase production rates. Is it worth it?

Analyzing cost-effectiveness is key. A machine that costs $30,000 may seem appealing, but how long will it last? Durability and maintenance costs can skyrocket. Some machines have an average lifespan of only five years, leading to hidden expenses. Industry averages show that companies could lose up to 20% of their profits if machines underperform.

Efficiency also matters. A more expensive machine might yield better quality mesh, which can command higher prices in the market. If the machine doesn’t meet industry standards, sales could plummet. Research indicates that 40% of businesses fail to consider long-term operational costs. Reflecting on these factors can help in making a more informed decision.