5 Secrets to Finding the Best Quick Turn CNC Machining Services

The demand for quick turn CNC machining has surged in recent years, driven by the need for rapid prototyping and agile manufacturing solutions across various industries. According to a recent industry report, the CNC machining market is expected to reach USD 100 billion by 2025, with quick turn services playing a crucial role in this growth. Companies are increasingly prioritizing speed without sacrificing quality, as the global market increasingly hinges on the ability to deliver components faster than ever before. As such, identifying the best quick turn CNC machining services is essential for businesses aiming to enhance their production capabilities and maintain a competitive edge. This blog will reveal five critical secrets to help you navigate the landscape of quick turn CNC machining services effectively.

Understanding Quick Turn CNC Machining Services and Their Importance

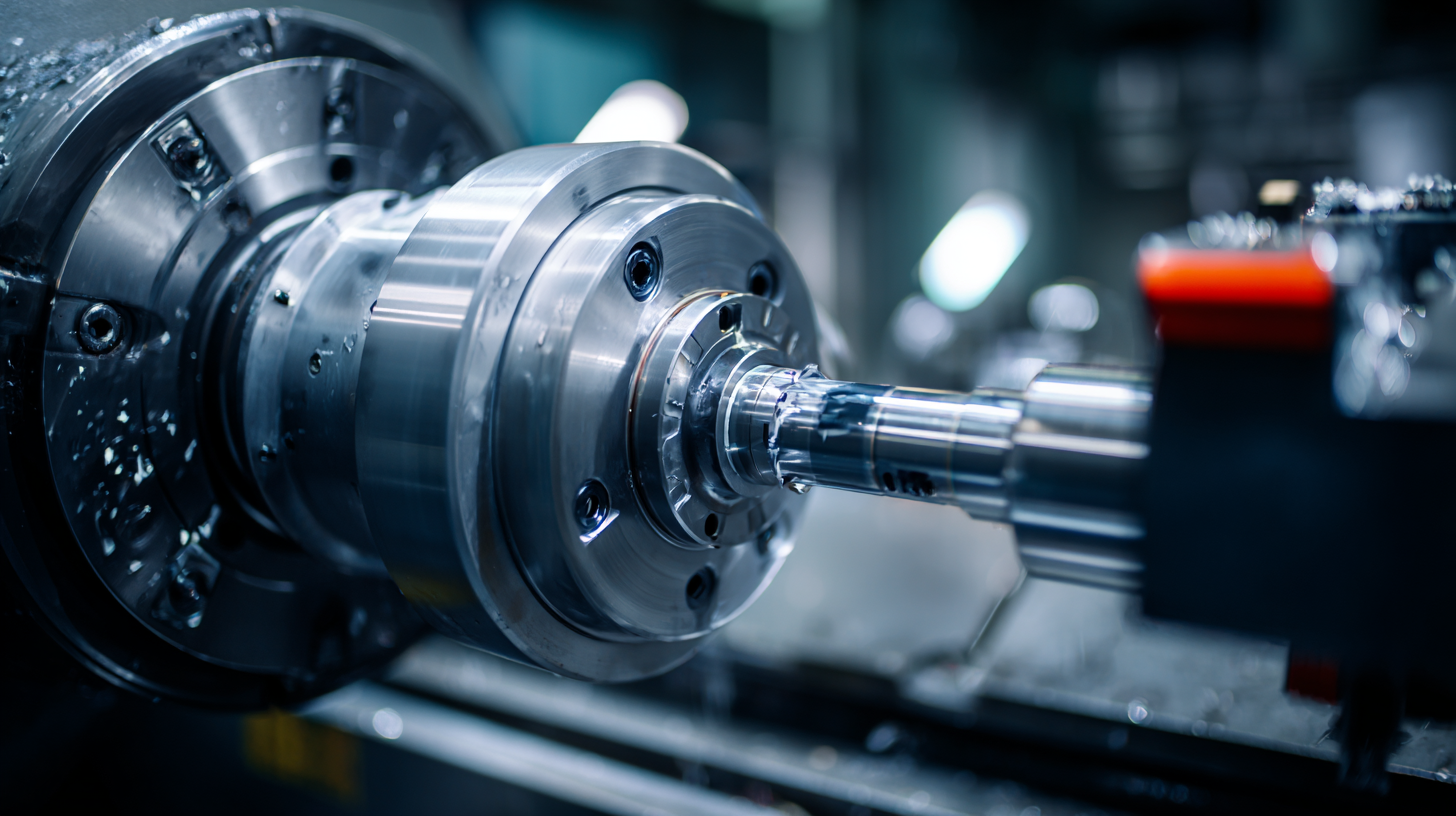

Quick turn CNC machining services play a crucial role in various industries, particularly in the manufacturing sector, where speed and precision are paramount. This method involves the use of computer-controlled machines that can produce complex parts quickly, allowing businesses to reduce lead times significantly. The importance of quick turn services comes into play especially when a company needs prototypes or small batches of components to test design concepts or meet urgent orders without compromising on quality.

Understanding the nuances of quick turn CNC machining services is essential for businesses seeking to stay competitive. These services not only offer rapid production capabilities but also ensure high accuracy, which is vital for parts that fit within tighter tolerances. Moreover, with advancements in technology, many providers are now able to handle a wider range of materials, enabling customers to select options that best suit their specific needs. This adaptability in materials and processes demonstrates the value of quick turn services in responding to dynamic market demands.

5 Secrets to Finding the Best Quick Turn CNC Machining Services

| Dimension | Details |

|---|---|

| Lead Time | 24-72 hours for prototypes |

| Materials Offered | Aluminum, Steel, Plastic, Exotic Alloys |

| Machining Tolerances | Up to ±0.001 inches |

| Quality Certifications | ISO 9001, AS9100 |

| Customer Support | 24/7 support via phone and email |

| Prototype Capabilities | High-speed machining for rapid prototyping |

Key Factors to Evaluate When Selecting a CNC Machining Provider

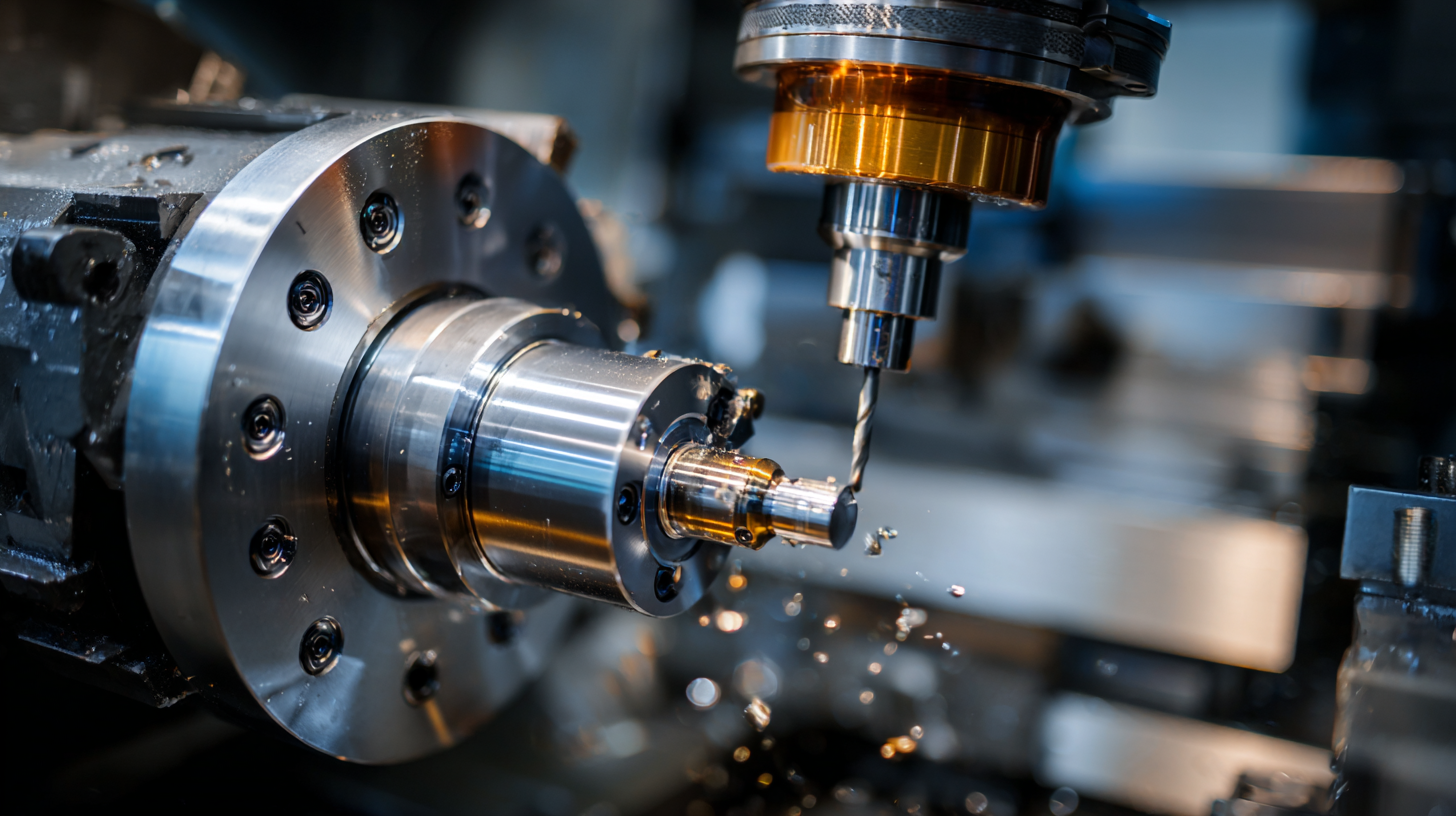

When selecting a CNC machining provider, several key factors should be evaluated to ensure you find the best service for your needs. First, assess the provider's equipment and technology. High-quality, up-to-date machines can significantly enhance precision and efficiency in production. Look for providers that invest in advanced CNC technologies, which often translate into better surface finishes and intricate detail capabilities.

Another crucial factor is the provider’s experience and expertise in your specific industry. Firms that specialize in your field are likely to understand the unique challenges and requirements of your projects. Request case studies or examples of previous work to gauge their level of competency and innovation. Lastly, consider their communication and customer service approach. A responsive and transparent provider will keep you informed throughout the manufacturing process, providing updates and addressing any concerns promptly, which can greatly affect the overall success of your project.

Analyzing Customer Reviews and Testimonials for Quality Assurance

When seeking the best quick turn CNC machining services, customer reviews and testimonials serve as invaluable tools for quality assurance. A recent industry report from CIMdata indicates that nearly 70% of consumers trust online reviews as much as personal recommendations, highlighting their significant impact on purchasing decisions. Potential clients can harness this data by assessing feedback across platforms like Google, Yelp, and industry-specific forums to gauge the reliability of machining service providers.

Examining the specifics of customer experiences can further illuminate the strengths and weaknesses of a machining service. According to a survey by the Association for Manufacturing Technology (AMT), 82% of companies report that effective communication and timely delivery are paramount in selecting a CNC machining partner. Reviews that emphasize these elements can help prospective clients narrow their options and find a service that aligns with their project timelines and quality expectations. By prioritizing credible testimonials, businesses can ensure they choose a machining service that consistently delivers superior results, grounded in reliable customer feedback.

The Role of Technology and Equipment in CNC Machining Excellence

In the realm of CNC machining, technology and equipment play a pivotal role in determining the quality and efficiency of services offered. According to a recent industry report from Grand View Research, the global CNC machine market is expected to reach $100 billion by 2025, fueled by advancements in automation and precision engineering. High-quality CNC machining relies heavily on advanced technologies such as multi-axis machines, which enhance the capability to produce complex parts with tight tolerances. These machines utilize sophisticated software for design and simulation, allowing for real-time adjustments that minimize errors and reduce production time.

Moreover, the integration of IoT (Internet of Things) in CNC machining has transformed traditional workflows. A 2021 survey by Deloitte revealed that over 70% of manufacturers are investing in smart technologies, enabling predictive maintenance and optimized performance tracking. This connectivity ensures that machinery operates at peak efficiency, translating to faster turnaround times for customers seeking quick turn services.

Embracing cutting-edge equipment not only streamlines processes but also increases the competitiveness of CNC machining services in today’s fast-paced market.

Tips for Effective Communication with CNC Machining Manufacturers

Effective communication with CNC machining manufacturers is crucial for achieving the best results during the quick turn machining process. The first tip is to clearly define your project requirements. Provide detailed specifications, including dimensions, tolerances, materials, and finish. The more precise you are with your expectations, the easier it will be for the manufacturer to produce parts that meet your needs.

Another important aspect of communication is establishing a strong relationship with your chosen CNC provider. Engage in regular discussions to address any concerns and provide feedback throughout the manufacturing process. This collaborative approach not only fosters trust but also allows for adjustments to be made in real time, ensuring that the final product aligns closely with your vision.

Lastly, don’t hesitate to ask questions. A reliable CNC manufacturer will be open to discussing their processes and capabilities. Inquire about their equipment, experience, and quality control measures. This will help you gauge their expertise and ensure that they can meet your project's demands efficiently.

5 Secrets to Finding the Best Quick Turn CNC Machining Services

This chart illustrates the importance level (on a scale from 1 to 10) of various factors to consider when choosing quick turn CNC machining services. Quality assurance is paramount, followed closely by turnaround time and effective communication with manufacturers.