Navigating the Future: How Best Rapid CNC Machining Will Shape Industry 2025 Trends

As we look ahead to 2025, the landscape of manufacturing is poised for transformative changes, driven by advancements in technology and evolving industry demands. Among the most impactful innovations is rapid CNC machining, which promises to revolutionize how products are designed and produced. This blog will explore the pivotal role of rapid CNC machining, particularly from leading manufacturing hubs in China, and its implications for industry trends in the coming years. By enabling faster production times, enhanced precision, and greater flexibility, rapid CNC machining is becoming a cornerstone of effective manufacturing strategies.

From automotive to aerospace, businesses are increasingly turning to this cutting-edge technology not only to meet consumer demands but also to innovate and stay competitive in a fast-paced market. Join us as we navigate the future of manufacturing and discover how rapid CNC machining will shape the trends of 2025 and beyond.

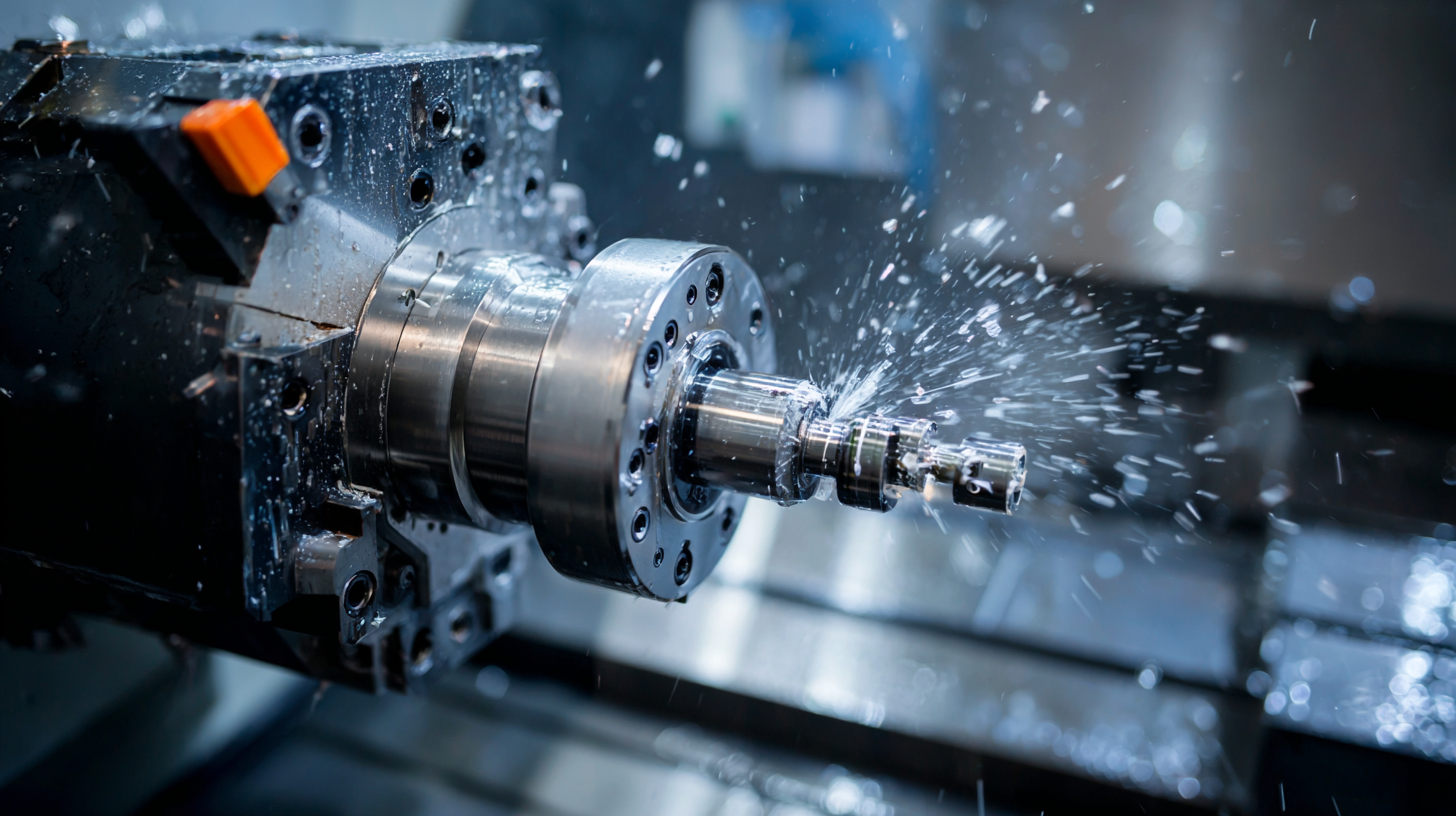

The Rise of Rapid CNC Machining: A Game Changer for Manufacturing

The rise of rapid CNC machining is revolutionizing the manufacturing landscape, making it a game changer for industries across the board. This innovative technology streamlines the production process, allowing for quicker turnaround times and enhanced precision. As businesses face increasing demands for customization and shorter lead times, rapid CNC machining emerges as a vital solution, enabling manufacturers to meet the evolving needs of their clients effectively.

Moreover, the integration of advanced CNC machining techniques fosters a culture of innovation in manufacturing. By facilitating rapid prototyping and iterative design processes, this technology empowers engineers and designers to experiment freely without the constraints of traditional manufacturing methods. As a result, companies can bring products to market faster while maintaining high quality. With the trend towards automation and smart manufacturing, rapid CNC machining will likely play a pivotal role in shaping industry standards and practices by 2025, driving efficiency and sustainability in production.

Key Market Drivers: What Will Shape the CNC Industry by 2025?

As we look forward to 2025, several key market drivers are set to reshape the CNC industry profoundly. The global CNC machinery market is projected to experience significant growth, increasing from USD 116.32 billion in 2025 to an estimated USD 182.34 billion by 2034. This trend highlights the growing reliance on advanced manufacturing technologies across various sectors, including aerospace, automotive, and medical devices.

One of the primary factors fuelling this growth is the increasing demand for precision engineering and automated solutions. Manufacturers are seeking to optimize their production processes, reduce waste, and enhance product quality. This shift towards efficiency not only improves profitability but also meets the evolving consumer expectations for high-quality and customized products.

**Tips for Industries Adapting to CNC Trends:**

- Embrace automation: Investing in CNC technology can lead to improved precision and reduced labor costs.

- Stay updated with market research: Understanding market dynamics is crucial for making informed investment decisions.

- Focus on training: Ensure that your workforce is skilled in modern CNC technologies to maximize the benefits of new machinery.

With these considerations, industries poised to adapt to the technological advancements in CNC machining will find themselves at a significant advantage in the competitive landscape by 2025.

Navigating the Future: How Best Rapid CNC Machining Will Shape Industry 2025 Trends

| Trend | Description | Impact on Industry | Market Driver |

|---|---|---|---|

| Increased Automation | Integration of AI and robotics into CNC machining processes. | Higher efficiency and reduced operational costs. | Advancement in technology and labor shortages. |

| Sustainability Practices | Adoption of eco-friendly materials and processes. | Improved brand image and compliance with regulations. | Increased consumer awareness and regulatory pressure. |

| Customization Demand | Growing trend for personalized products and quick turnarounds. | Greater market share and customer loyalty. | Shift in consumer preferences and competitive pressure. |

| Integrated Supply Chains | Collaboration between manufacturers and suppliers for streamlined operations. | Improved agility and responsiveness to market changes. | Globalization and digital transformation. |

| Data-Driven Decision Making | Utilization of big data analytics for process optimization. | More informed decisions, leading to cost savings. | Advancements in data collection and analysis tools. |

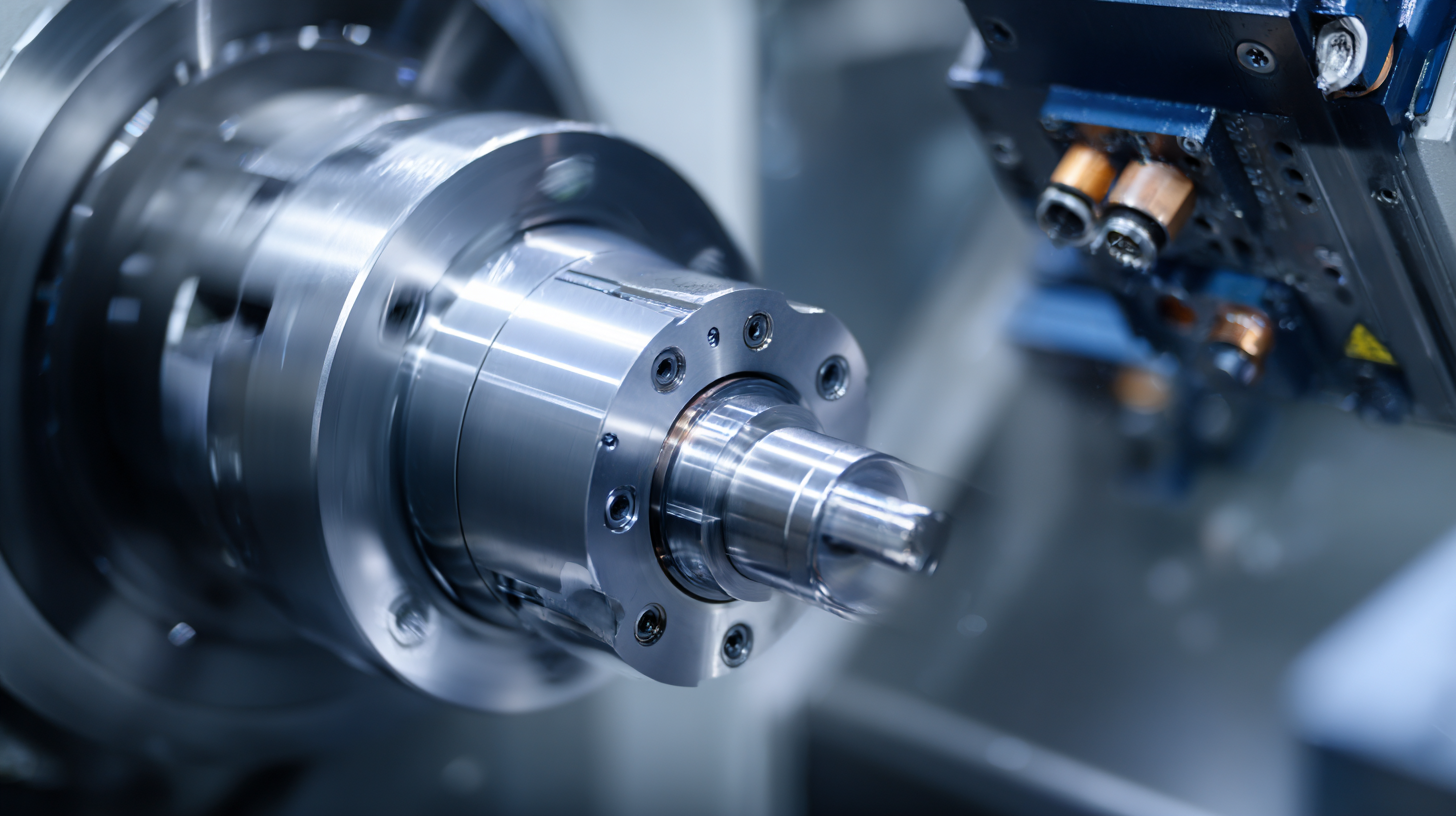

Emerging Technologies: Innovations Driving Rapid CNC Machining Forward

The landscape of rapid CNC machining is undergoing a significant transformation, driven by emerging technologies that are reshaping the industry. As the demand for high-precision and multi-axis machining centers rises, the CNC machine tools market is projected to grow substantially by 2029. Innovations such as artificial intelligence and machine learning are at the forefront, enabling smarter manufacturing processes that enhance productivity across various sectors. These technologies not only improve operational efficiency but also set new standards for precision and sustainability in production.

The integration of advanced digital manufacturing techniques is vital for manufacturers who seek to remain competitive in a rapidly evolving market. From intelligent production networks to groundbreaking applications in fields like aerospace and agriculture, the future of CNC machining hinges on the effective utilization of cutting-edge technologies. The recent establishment of the world's first Robot & AI Museum exemplifies the growing recognition and significance of these innovations, highlighting their transformative potential in driving the fourth industrial revolution. As we approach 2025, embracing these advancements will be essential for industries looking to innovate and thrive in an increasingly automated world.

Sustainability Considerations: The Environmental Impact on CNC Practices

As we look towards 2025, sustainability is becoming a pivotal concern within the CNC machining sector. According to a report by the International Federation of Robotics, over 1.2 million industrial robots are expected to be in use globally by 2025, many of which are designed with energy-efficient technologies. This trend reflects a growing commitment to reducing the environmental impact associated with CNC practices. Incorporating automation not only boosts production efficiency but also lends itself to decreased material waste, aligning with the increasing demand for eco-friendly manufacturing processes.

Moreover, a study conducted by McKinsey indicates that companies embracing sustainable practices, including the adoption of rapid CNC machining, are projected to see a 15-20% increase in profitability by 2025. The shift towards renewable energy sources in CNC operations is also gaining momentum; reports show that around 35% of energy used in manufacturing will come from renewable sources in the next few years. This transition not only mitigates the carbon footprint of CNC machining but also positions businesses favorably in an evolving market that increasingly prioritizes sustainability. The future of CNC machining will undoubtedly be shaped by these environmental considerations, guiding practices that meet both production needs and ecological responsibilities.

Navigating the Future: CNC Machining Sustainability Trends (2025)

Future Workforce: Skills and Training Needs for CNC Machining in 2025

As the landscape of CNC machining evolves, the workforce must adapt to meet the demands of 2025. According to a report by the National Association of Manufacturers, the manufacturing sector is projected to face a skills gap of about 2.1 million workers by 2030. This gap highlights the urgent need for specialized training programs that equip workers with the skills necessary to excel in advanced CNC machining environments.

Future CNC machinists will be expected to possess not only technical skills but also proficiency in digital technologies and data analysis. With the rise of Industry 4.0, integrating automation and smart manufacturing processes into CNC operations is essential. A study by Deloitte emphasized that 81% of manufacturers agree that advanced technology adoption will be crucial for business success by 2025. Training initiatives must therefore focus on enhancing competencies in areas such as computer-aided design (CAD), computer-aided manufacturing (CAM), and programming languages like G-code to ensure the workforce is prepared for these technological advancements.

Additionally, fostering soft skills such as problem-solving, critical thinking, and adaptability will be pivotal in navigating the complexities of modern CNC machining. As industries continue to innovate, aligning educational curricula with these skills will be essential in producing a workforce that can thrive in an increasingly automated and interconnected environment.