5 Reasons Why Rapid CNC Machining is Your Best Option for Global Sourcing

In the fast-evolving world of manufacturing, rapid CNC machining has emerged as a pivotal strategy for companies seeking to optimize their global sourcing efforts. According to a report published by MarketsandMarkets, the CNC machining market is projected to grow from $64.1 billion in 2020 to $100.0 billion by 2025, reflecting a compound annual growth rate (CAGR) of 9.5%. This surge is largely driven by the increasing demand for precision components across various sectors, from aerospace to healthcare. Rapid CNC machining not only accelerates production times but also offers unparalleled accuracy and flexibility, making it an essential component for businesses aiming to stay competitive in a global marketplace. As manufacturers look to streamline operations while maintaining high-quality standards, understanding the advantages of rapid CNC machining becomes crucial for strategic sourcing decisions.

The Benefits of Rapid CNC Machining in Global Sourcing

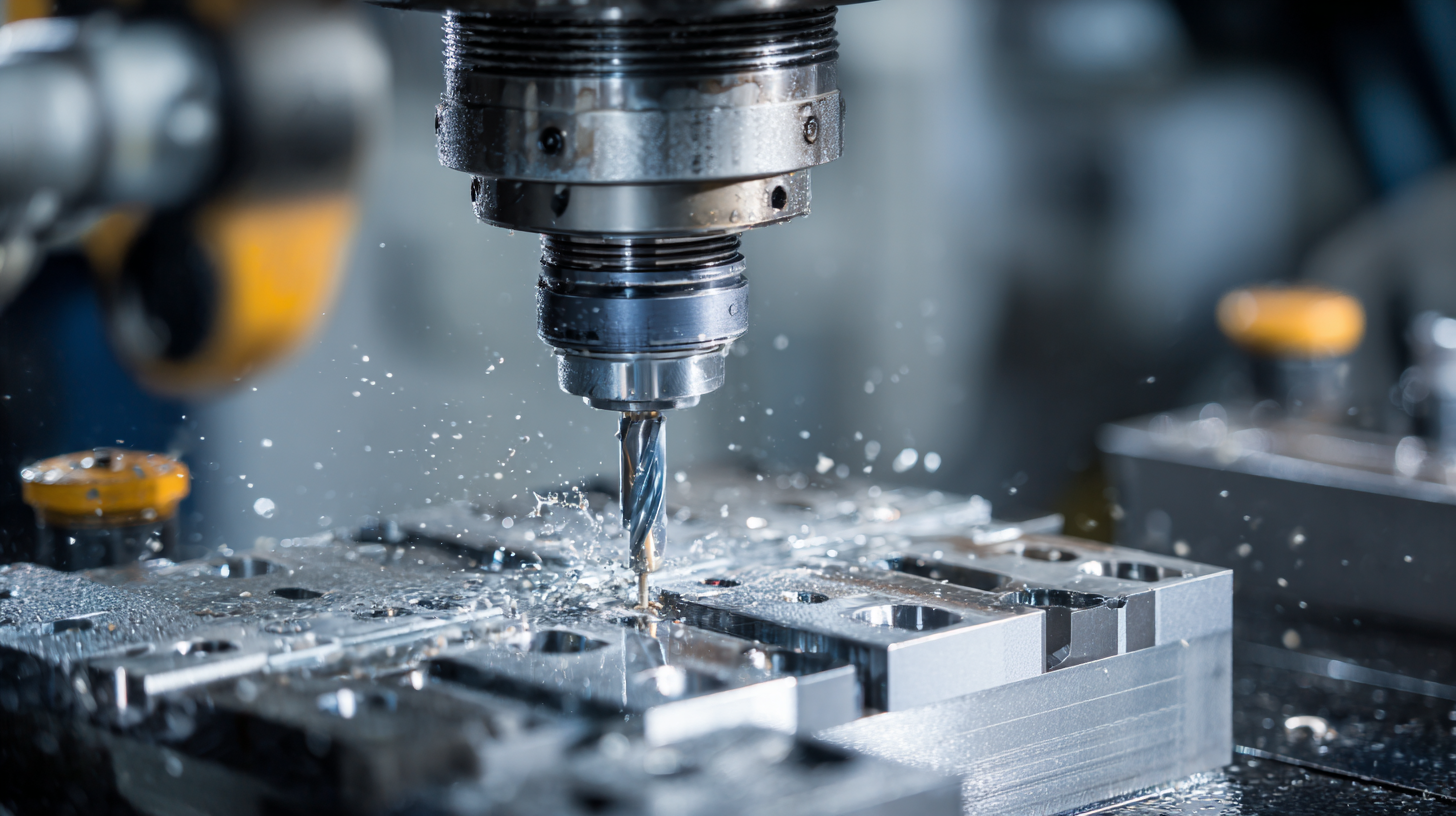

In the fast-paced world of global sourcing, rapid CNC machining offers a competitive edge that cannot be overlooked. One of the key benefits is the significant reduction in lead times. Traditional machining processes may take weeks or even months, but rapid CNC machining can deliver prototypes and final products in a matter of days. This agility allows companies to respond to market demands swiftly and stay ahead of competitors.

Another advantage is the precision and quality that CNC machining provides. With state-of-the-art technology, manufacturers can achieve intricate designs and high tolerances, ensuring the finished products meet stringent quality standards. This precision is particularly crucial when sourcing parts that require exact specifications, as it minimizes the risk of costly errors.

**Tips:** When considering rapid CNC machining for global sourcing, always check the capabilities of your manufacturer. Look for those who have experience with the specific materials and techniques you need. Additionally, establish clear communication channels to ensure that any adjustments to designs or timelines can be managed efficiently, reducing the risk of delays in your supply chain.

5 Reasons Why Rapid CNC Machining is Your Best Option for Global Sourcing

Streamlining Production: Speed and Efficiency in CNC Machining

In today’s fast-paced manufacturing landscape, rapid CNC machining stands out as a game-changer for global sourcing, particularly in the realm of medical devices. The integration of advanced digital manufacturing technologies has transformed production processes, enhancing speed and efficiency across various industries. This evolution not only accelerates time-to-market but also allows manufacturers to respond swiftly to changing consumer demands. As a result, companies can maintain competitiveness while upholding high standards of quality.

Moreover, the benefits of rapid CNC machining extend beyond mere speed. Experts have highlighted its role in refining medical device manufacturing by enabling precise machining and laser processing techniques. This advancement empowers manufacturers to create intricate designs and improve the functionality of medical equipment. A significant shift in prosthetic technology exemplifies this progress, where innovations now focus on enhancing performance while reducing costs. The collaboration between firms in this sector exemplifies how streamlined production processes can lead to breakthroughs in healthcare solutions, ultimately benefiting patients and the industry alike.

Cost-Effectiveness: Maximizing Your Budget with Rapid Machining

Rapid CNC machining has become a vital strategy for businesses looking to maximize their budgets while ensuring high-quality production. In today's fast-paced market, companies are seeking cost-effective solutions without sacrificing precision. By utilizing advanced CNC machining techniques, businesses can significantly reduce lead times and production costs, making this method ideal for global sourcing.

One key tip for maximizing your budget with rapid machining is to collaborate closely with your CNC manufacturer. Clear communication regarding your project requirements, timelines, and budget constraints can lead to more accurate estimates and fewer unexpected expenses. Additionally, consider simplifying your designs where possible. Streamlined designs not only cut costs but also facilitate more efficient machining processes.

Another important consideration is to leverage advanced technology. Invest in manufacturers who use the latest CNC machines and software, as these tools often provide better speed and accuracy, thus reducing waste and rework. This approach not only saves money but also enhances the overall quality of the finished product, positioning your business for success in a competitive global market.

5 Reasons Why Rapid CNC Machining is Your Best Option for Global Sourcing - Cost-Effectiveness: Maximizing Your Budget with Rapid Machining

| Factor | Description | Impact on Cost | Estimated Savings |

|---|---|---|---|

| Material Efficiency | Utilization of advanced materials can minimize waste. | Reduces initial material costs significantly. | Up to 20% savings on material costs. |

| Production Speed | Rapid CNC machining cuts down lead times. | Allows quicker time-to-market, reducing overhead. | Potentially 15% decrease in project cost. |

| Labor Costs | Automation reduces reliance on skilled labor. | Lower labor costs enhance overall budget efficiency. | Up to 30% savings in labor expenses. |

| Quality Control | Precision machining leads to higher quality parts. | Reduces costs associated with defects and rework. | Savings of up to 25% in rework costs. |

| Global Supply Chain | Access to international suppliers for competitive pricing. | Ensures cost-effectiveness across borders. | Potential savings of 10% in sourcing costs. |

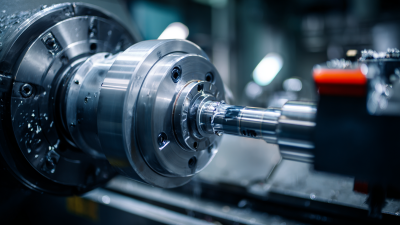

Quality Assurance: How Rapid CNC Machining Ensures Precision

Rapid CNC machining stands out in the realm of global sourcing due to its unwavering focus on quality assurance. With a remarkable accuracy level, often reaching tolerances as tight as ±0.001 inches, it significantly surpasses traditional manufacturing methods. This precision is critical in industries like aerospace and healthcare, where even minor deviations can lead to significant failures or safety hazards. According to a report by the National Institute of Standards and Technology, implementing advanced CNC technology can reduce scrap rates by up to 25%, emphasizing the cost-effectiveness of utilizing rapid machining solutions.

Furthermore, the quality assurance process in rapid CNC machining incorporates stringent inspection protocols. Operators leverage automated systems and advanced measurement tools that provide real-time feedback, ensuring that each component meets the specified requirements. A study by the International Journal of Advanced Manufacturing Technology has indicated that companies employing these practices report a 40% increase in customer satisfaction. This level of reliability not only enhances the product's integrity but also strengthens partnerships in the global supply chain, making rapid CNC machining a preferred choice for quality-driven businesses aiming for excellence.

Flexibility and Customization: Adapting Designs to Market Needs with CNC Machining

CNC machining has emerged as a powerful tool in global sourcing, primarily due to its inherent flexibility and customization capabilities. In a fast-paced market where consumer preferences can shift overnight, manufacturers need to adapt their designs quickly to stay competitive. CNC machining enables this level of responsiveness, allowing companies to make necessary adjustments to prototypes and final products with ease. Whether it’s altering dimensions or fine-tuning features, the precision of CNC technology ensures that modifications do not compromise quality.

CNC machining has emerged as a powerful tool in global sourcing, primarily due to its inherent flexibility and customization capabilities. In a fast-paced market where consumer preferences can shift overnight, manufacturers need to adapt their designs quickly to stay competitive. CNC machining enables this level of responsiveness, allowing companies to make necessary adjustments to prototypes and final products with ease. Whether it’s altering dimensions or fine-tuning features, the precision of CNC technology ensures that modifications do not compromise quality.

Moreover, the customization options available with CNC machining extend beyond mere adjustments; they encompass a broad range of materials and processes. This versatility allows businesses to create unique components tailored to specific market demands. As a result, companies can differentiate their products, increasing their market appeal and customer satisfaction. By leveraging CNC machining for customized solutions, businesses not only meet immediate market needs but also position themselves for future growth in an ever-evolving landscape.

Related Posts

-

Navigating the Future: How Best Rapid CNC Machining Will Shape Industry 2025 Trends

-

Maximizing Value: How Exceptional After-Sales Service and Low Repair Costs in Best Rapid CNC Machining Set You Apart

-

5 Secrets to Finding the Best Quick Turn CNC Machining Services

-

Exploring Unique Features and Applications of the Best Rapid CNC Machining Solutions

-

Finding Top Quality Suppliers for Best Precision CNC Machining Solutions

-

5 Compelling Reasons Why Best Rapid CNC Machining Is Essential for Your Business Success