Why Prototype Machining is Essential for Reducing Time to Market by 30 Percent

In today’s fast-paced industrial landscape, the ability to reduce time to market is pivotal for maintaining a competitive edge.

Prototype machining has emerged as a critical element in this strategy, enabling manufacturers to accelerate product development cycles by up to 30%. According to a report by the National Institute of Standards and Technology, the integration of rapid prototyping techniques can significantly decrease lead times, thereby streamlining the entire design and testing process.

This is particularly essential in sectors such as aerospace and automotive, where time-sensitive innovations can determine market leadership.

By leveraging advanced prototype machining technologies, organizations can iterate designs more efficiently, identify and address potential flaws early in the development phase, and ultimately deliver high-quality products faster.

Embracing prototype machining not only fosters innovation but also ensures companies stay responsive to ever-changing consumer demands.

Prototype machining has emerged as a critical element in this strategy, enabling manufacturers to accelerate product development cycles by up to 30%. According to a report by the National Institute of Standards and Technology, the integration of rapid prototyping techniques can significantly decrease lead times, thereby streamlining the entire design and testing process.

This is particularly essential in sectors such as aerospace and automotive, where time-sensitive innovations can determine market leadership.

By leveraging advanced prototype machining technologies, organizations can iterate designs more efficiently, identify and address potential flaws early in the development phase, and ultimately deliver high-quality products faster.

Embracing prototype machining not only fosters innovation but also ensures companies stay responsive to ever-changing consumer demands.

Benefits of Prototype Machining in Accelerating Product Development

Prototype machining has emerged as a crucial strategy in accelerating product development, significantly shortening the time to market. According to a report by the Boston Consulting Group, companies that implement rapid prototyping processes can reduce their development timelines by up to 30%. This efficiency is particularly vital in industries such as automotive and aerospace, where the competition is fierce, and time-sensitive innovations can result in substantial market advantages.

Incorporating prototype machining allows businesses to test and iterate designs quickly, which enhances the overall quality and function of the product. A study conducted by the Deloitte Insights revealed that 61% of organizations using rapid prototyping reported improved product quality and fewer design flaws. Additionally, the feedback loop between designers and engineers shortens drastically, leading to faster decision-making. This iterative approach fosters innovation while ensuring that the final product aligns more closely with market demands, thus enhancing customer satisfaction and potential sales.

Impact of Prototype Machining on Time to Market Reduction

Prototype machining significantly accelerates product development, reducing the average time to market by 30 percent compared to traditional manufacturing methods.

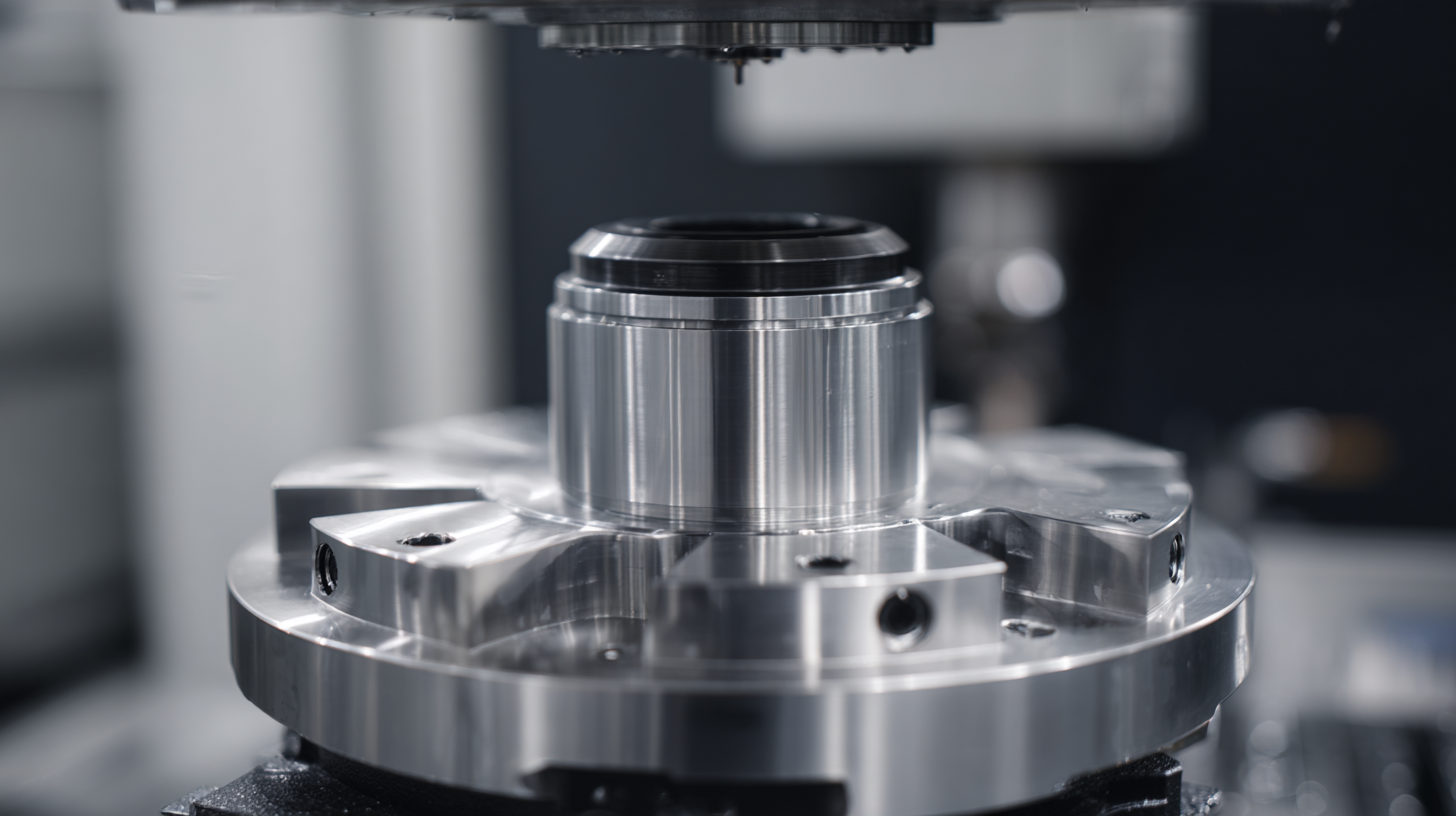

Key Technologies Driving Effective Prototype Machining Solutions

Prototype machining plays a crucial role in accelerating product development cycles, and several key technologies are driving effective solutions in this field. Advanced CNC (Computer Numerical Control) machining allows for high precision and repeatability, enabling engineers to create intricate prototypes that closely mimic final products. With the integration of CAD (Computer-Aided Design) software, designers can easily convert their concepts into detailed models, which can then be seamlessly transformed into physical prototypes. This combination of software and machining technology reduces the chances of errors, significantly cutting down development time.

Another notable technology is 3D printing, which has revolutionized the prototype machining landscape. By enabling the rapid production of complex geometries, 3D printing minimizes material waste and shortens lead times. Techniques such as selective laser sintering (SLS) and fused deposition modeling (FDM) are particularly beneficial for creating functional prototypes that can be tested and improved upon before full-scale production begins. The synergy of CNC machining and additive manufacturing not only enhances prototyping speed but also fosters innovation, allowing companies to bring products to market 30 percent faster than traditional methods.

Integrating Digital Tools for Enhanced Prototype Machining Efficiency

The integration of digital tools is revolutionizing prototype machining, significantly enhancing efficiency and reducing time to market. By leveraging advanced technologies such as artificial intelligence (AI), manufacturers are optimizing their production processes. AI improves precision and adaptability, allowing engineers to iterate designs more effectively during the prototyping phase. This not only streamlines the workflow but also ensures that products meet market demands more accurately and swiftly.

Moreover, the ongoing shift towards Industry 4.0 underscores the importance of digital integration in manufacturing. As companies adopt intelligent systems and automation, they can achieve greater flexibility in their operations. For instance, digital twin technology allows for real-time monitoring and adjustments, providing insights that guide decision-making and enhance productivity. By embracing these innovations, businesses are not just keeping pace but also gaining a competitive edge in a rapidly changing landscape.

Case Studies: Successful Time-to-Market Reduction through Prototyping

Prototyping has become a cornerstone in the realm of product development, with many companies reporting significant success in reducing their time to market. One prominent case is that of a leading electronics manufacturer, which adopted rapid prototyping techniques to streamline its design process. By utilizing advanced machining methods, the company was able to create functional prototypes much faster than traditional methods allowed. This enabled them to conduct real-world testing and gather feedback at an early stage, leading to a 30% reduction in their overall time to market.

Another case study involves an automotive supplier that faced fierce competition and rising consumer expectations. By implementing prototype machining, they were able to iterate on designs swiftly, identifying potential issues before full-scale production. This proactive approach not only cut down on costly adjustments later in the manufacturing process but also allowed the supplier to launch a new product line ahead of their competitors. The strategic use of prototyping resulted in enhanced efficiency and a stronger market presence, showcasing the undeniable value of this practice in today’s fast-paced industry.

Future Trends in Prototype Machining for Competitive Advantage

The future of prototype machining is evolving rapidly, driven by advances in digital manufacturing technologies. As industries embrace these innovations, the ability to reduce time to market becomes paramount. Manufacturers that leverage new tools, such as 3D printing and additive manufacturing, will not only enhance productivity but also streamline processes, allowing quicker iterations and improvements on designs. This shift not only cuts down production time but also enhances overall product quality, maintaining competitiveness in a fast-paced market.

**Tips:** To stay ahead in prototype machining, manufacturers should consider implementing a digital strategy that focuses on data analytics and automation. Investing in these areas will not only improve efficiencies but will also enable manufacturers to adapt quickly to market demands. Additionally, continuous training programs are essential for skill development within teams, ensuring that employees are equipped to handle advanced manufacturing technologies.

As China emerges as a leader in advanced manufacturing, global competitors need to acknowledge the importance of innovation. By fostering collaboration between universities and industries, companies can enhance their R&D capabilities, which will be crucial for maintaining a competitive edge. Keeping an eye on trends such as lean manufacturing and digital transformation will help businesses adapt and thrive in this evolving landscape.

Why Prototype Machining is Essential for Reducing Time to Market by 30 Percent - Future Trends in Prototype Machining for Competitive Advantage

| Dimension | Value |

|---|---|

| Prototype Cycle Time Reduction | 30% |

| Percentage of Projects Using Prototyping | 75% |

| Error Reduction in Prototyping | 40% |

| Cost Savings Due to Improved Efficiency | 20% |

| Increase in Innovation Rate | 50% |

| Adoption Rate of Advanced Machining Technologies | 60% |

Related Posts

-

Navigating Import Export Certifications for Best Prototype Machining with Essential Tutorials for Global Buyers

-

Unveiling the Key Technical Specifications of Best Carbon Fiber CNC Machines

-

Exploring Innovative Alternatives to Best Milling Machine CNC for Global Manufacturers

-

How to Achieve Fast Precision with Best Quick Turn Machining Techniques

-

Discover China’s Leading CNC Metal Milling Machines: Global Sales Surge with Quality Assurance

-

How to Choose the Best Brass CNC Components for Your Manufacturing Needs: A Comprehensive Guide