Top 5 Precision CNC Machining Techniques for Optimal Results

In the rapidly evolving landscape of modern manufacturing, precision CNC machining remains a cornerstone for achieving unparalleled accuracy and efficiency. According to a report by MarketsandMarkets, the global CNC machining market is projected to reach $100 billion by 2025, highlighting its critical role in sectors such as aerospace, automotive, and electronics. As industries strive for higher productivity and stringent quality standards, mastering the intricacies of precision CNC machining techniques is essential for optimal results.

Expert John Smith, a renowned authority in the field of precision machining, emphasizes the importance of utilizing advanced techniques to maintain competitive advantage. "The right CNC machining methods not only enhance precision but also significantly reduce waste and operational costs," he notes. This sentiment reflects a growing recognition of how adopting best practices in precision CNC machining can lead to improved profit margins and sustainability in production.

As we explore the top five precision CNC machining techniques, it becomes evident that these methods are not just tools of the trade; they are vital strategies for industries aiming to navigate the complexities of today’s manufacturing environment. Recognizing the pivotal role of precision in CNC machining sets the stage for substantial advancements in production processes and overall industry innovation.

Overview of CNC Machining Techniques

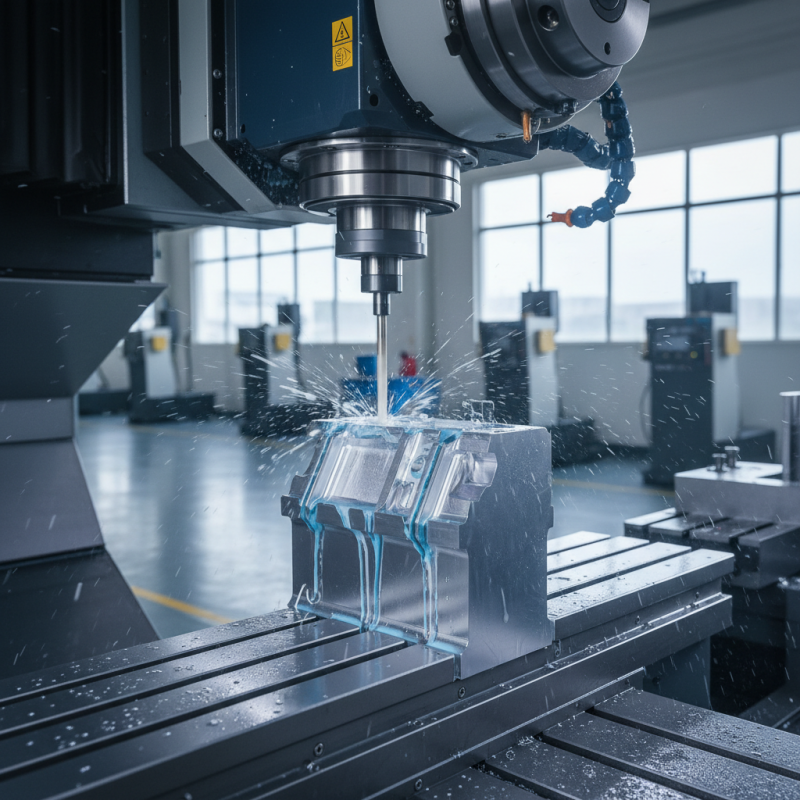

CNC (Computer Numerical Control) machining is a precise manufacturing process that utilizes computer-controlled tools to create complex shapes and features with high accuracy. There are several techniques within CNC machining that cater to various applications, allowing for a versatile approach to production. Popular methods include milling, turning, and grinding, each with its unique benefits and suitable use cases. Milling utilizes rotating cutting tools to remove material from a workpiece, making it ideal for creating intricate designs, while turning involves rotating the material against a stationary cutting tool, providing excellent results for cylindrical parts.

Another prominent technique is electrical discharge machining (EDM), which leverages electrical discharges to erode material, allowing for the creation of complex geometries in hard metals. This method is particularly useful when producing molds and dies, where precision is crucial. Additionally, laser machining employs high-powered lasers to cut and engrave materials with impressive accuracy and speed. Each of these techniques showcases the adaptability and precision of CNC machining, making it integral to modern manufacturing across various industries. The selection of an appropriate technique hinges on the specific requirements of the project, such as material type, desired finish, and production volume.

Top 5 Precision CNC Machining Techniques for Optimal Results

Understanding Precision in CNC Machining

In the realm of CNC machining, precision is paramount for achieving optimal results. Precision refers to the degree to which the machined components meet the specified dimensions and tolerances. It is essential for ensuring that parts fit perfectly and function as intended, especially in industries such as aerospace, automotive, and medical device manufacturing. Understanding the nuances of precision in CNC machining can significantly enhance the quality of manufactured products.

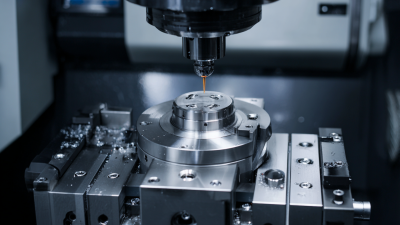

One key aspect of achieving precision is the use of advanced CNC machining techniques. Techniques such as 5-axis machining, laser cutting, and precision grinding allow for more intricate designs and tighter tolerances. These methods not only improve the accuracy of cutting paths but also reduce the likelihood of errors during the machining process. Incorporating these technologies helps manufacturers achieve a higher level of detail and improve overall efficiency.

**Tips for Enhancing Precision in CNC Machining:**

- Regularly calibrate your CNC machines to ensure they maintain the correct settings and reduce deviations over time.

- Utilize high-quality cutting tools and materials designed specifically for precision work, as they can greatly influence the accuracy of the final product.

- Implement thorough quality control measures, including the use of measurement tools like calipers and micrometers, to consistently check the dimensions of machined parts.

Top 5 Precision CNC Machining Techniques Explained

Precision CNC machining is an essential aspect of modern manufacturing, allowing for intricate designs and high tolerances that are critical in various industries, including aerospace, automotive, and medical. Among the most effective techniques employed in CNC machining, five stand out for their ability to achieve optimal results. These include 5-axis machining, high-speed machining, precision grinding, electrical discharge machining (EDM), and CNC laser cutting.

5-axis machining is particularly advantageous as it allows for complex geometries to be milled in a single setup, significantly reducing the time and cost involved in manufacturing. A report from the International Journal of Advanced Manufacturing Technology indicates that 5-axis machines can improve efficiency by up to 30% compared to traditional 3-axis machines. High-speed machining technology enables faster cutting speeds and feeds, thereby enhancing productivity while improving tool life, which is critical in meeting tight deadlines and maintaining quality.

Additionally, precision grinding is essential for achieving surface finishes that meet stringent specifications, especially in industries like aerospace where performance and safety are paramount. According to a study by the Society of Manufacturing Engineers, the adoption of precision grinding has played a significant role in the increase of component accuracy, reducing variability in production runs by up to 25%. Meanwhile, EDM and CNC laser cutting provide solutions for intricate designs that would otherwise be impossible to achieve with conventional machining. Together, these techniques form a robust framework for achieving the highest standards of precision in CNC machining, ensuring manufacturers can meet ever-evolving industry demands.

Factors Affecting CNC Machining Accuracy

When it comes to CNC machining, maintaining high levels of accuracy is crucial for producing quality parts. Several factors can significantly influence the precision of CNC machining processes. One of the primary aspects is the machine's mechanical construction. Rigid and robust machine components, such as the frame and spindle, ensure less vibration and better stability, ultimately leading to enhanced precision. Additionally, the quality of the cutting tools used plays a vital role; tools must be sharp and made from suitable materials to reduce wear and maintain cutting consistency.

Another significant factor is the setup of the CNC machine itself. Proper calibration and alignment of the machine's axes are essential to ensure accurate movement and positioning. Any misalignment can lead to tolerances being exceeded and affect the final product's fit and function. Furthermore, the selection of optimal machining parameters—such as feed rate, cutting speed, and depth of cut—also influences accuracy. Balancing these parameters can minimize thermal expansion and tool deformation while improving surface finish. Hence, attention to these details during the setup and operation phase is paramount to achieving the desired accuracy in CNC machining.

Top 5 Precision CNC Machining Techniques for Optimal Results - Factors Affecting CNC Machining Accuracy

| Technique | Accuracy Level | Material Types | Common Applications | Factors Affecting Accuracy |

|---|---|---|---|---|

| Milling | ±0.005 mm | Aluminum, Steel, Plastic | Parts, Housings, Complex Geometries | Tool wear, Machine calibration |

| Turning | ±0.01 mm | Copper, Stainless Steel | Shafts, Rings, Cylinders | Speed, Feed rate |

| EDM (Electrical Discharge Machining) | ±0.002 mm | Tool Steel, Carbide | Molds, Dies, Intricate Parts | Electrode wear, Spark gap |

| Laser Cutting | ±0.1 mm | Steel, Acrylic, Wood | Signage, Architectural Components | Material thickness, Energy settings |

| 3D Printing | ±0.1 mm | Plastic, Resin, Metal | Prototyping, Custom Parts | Layer adhesion, Print speed |

Applications of Precision CNC Machining in Industries

Precision CNC machining plays a crucial role across various industries, offering unparalleled accuracy and efficiency in manufacturing processes. In the aerospace sector, for instance, it is employed to create complex components that meet stringent safety and performance standards. Parts such as housings, brackets, and turbine blades are often produced using advanced CNC techniques, ensuring lightweight yet durable components that enhance overall aircraft performance and fuel efficiency.

Moreover, the automotive industry significantly benefits from precision CNC machining, utilizing it in the production of intricate engine parts, drive systems, and suspension components. The ability to achieve tight tolerances is essential for ensuring compatibility and functionality within the vehicle's systems.

Beyond these sectors, precision machining finds applications in medical device manufacturing, where it is vital for producing high-precision surgical instruments and prosthetics that require meticulous attention to detail to meet rigorous health regulations. Overall, the versatility and precision offered by CNC machining make it indispensable in numerous fields, contributing to innovation and enhancement in product quality.

Related Posts

-

7 Best Practices for Precision CNC Machining: Achieving 99.9% Accuracy in Manufacturing

-

Finding Top Quality Suppliers for Best Precision CNC Machining Solutions

-

Maximizing Value: How Exceptional After-Sales Service and Low Repair Costs in Best Rapid CNC Machining Set You Apart

-

Navigating the Future: How Best Rapid CNC Machining Will Shape Industry 2025 Trends

-

Exploring CNC Metal Milling Machines at the 138th Canton Fair 2025: Industry Trends and Innovations

-

Unlocking Precision: How Fast CNC Machining Revolutionizes Manufacturing Efficiency by 30%+