Unleashing the Power of Chinese Manufacturing with the Best CNC Aluminum Milling Machines

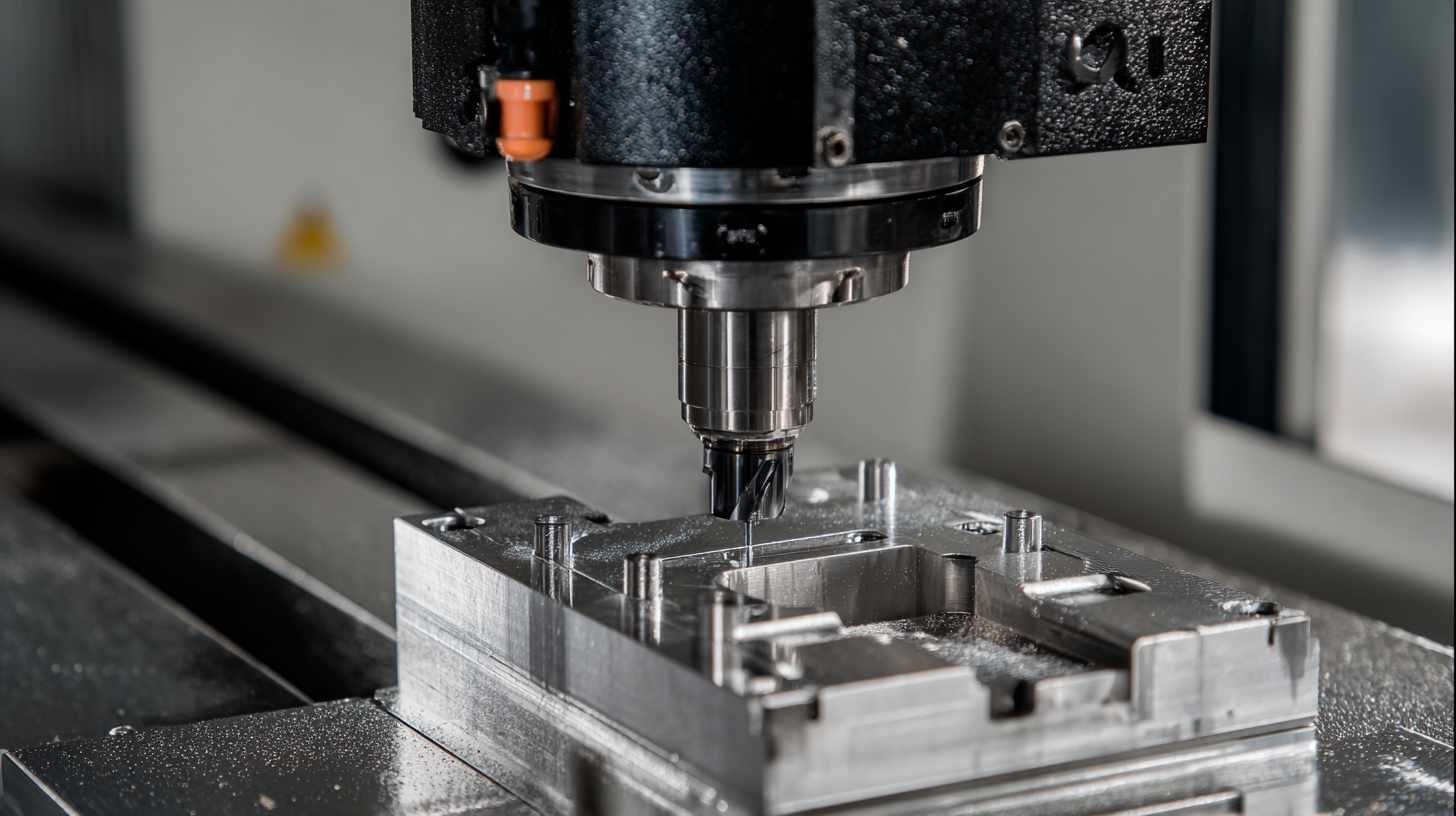

As we approach 2025, the landscape of manufacturing is undergoing a significant transformation, particularly in China, where innovation and technology convergence are reshaping production capabilities. Central to this evolution is the CNC aluminum milling machine, a vital tool that enables manufacturers to achieve precision and efficiency in their operations.

This blog explores the dynamic trends in the Chinese manufacturing industry, delving into advancements in CNC technology and its impact on productivity and cost-effectiveness. We will also provide insights on how to leverage these machines to enhance manufacturing processes, ensuring businesses remain competitive in an increasingly global marketplace.

Join us as we unveil the immense potential of CNC aluminum milling machines and their role in driving the future of Chinese manufacturing.

Choosing the Right CNC Aluminum Milling Machine for Your Needs

When it comes to selecting the right CNC aluminum milling machine, understanding your specific needs and the capabilities of the machines available is critical. According to a report by Technavio, the global CNC milling machine market is projected to grow at a CAGR of over 5% between 2021 and 2025. This growth is driven by advancements in machine precision and productivity, making it essential for businesses to choose machines that align with their production goals.

First, consider the types of parts you’ll be milling. For instance, if you are focused on high-volume production, investing in a high-speed CNC aluminum milling machine with advanced features, such as multi-axis capabilities and automation, can significantly enhance efficiency. Research from Market Research Future indicates that multi-axis CNC machines are increasingly preferred for their versatility and ability to produce complex geometries with reduced setup time.

Additionally, evaluate the machine's compatibility with different types of aluminum alloys. Data from the Aluminum Association highlights that the demand for lightweight, high-strength materials in industries such as aerospace and automotive is driving the need for specialized milling machines. Selecting a machine that supports a broad range of aluminum types ensures you can adapt to changing market demands and optimize your production capabilities effectively.

Key Features to Look for in a High-Quality CNC Machine

When considering high-quality CNC aluminum milling machines, it's essential to focus on key features that enhance manufacturing efficiency and product quality. One prominent advancement in this field is the integration of ultrasonic sensors, which have been shown to correlate sound with the quality of composite materials during processing. This technology enables real-time monitoring and analysis of the milling process, allowing operators to detect irregularities that might affect the final product's integrity.

Moreover, the design and structural rigidity of the CNC machine play a crucial role in its performance. A robust structure ensures that the machine can withstand the stresses of milling operations, thereby minimizing vibrations and deviations during the machining process. This results in improved precision and surface finish of the machined aluminum parts. Additional features such as high spindle speeds, advanced cooling systems, and user-friendly control interfaces can greatly enhance productivity and ease of use, making these machines indispensable tools in modern manufacturing setups.

Unleashing the Power of Chinese Manufacturing: CNC Aluminum Milling Machines Features

This bar chart illustrates key features and their ratings for high-quality CNC aluminum milling machines, showcasing their importance in boosting the efficiency and capabilities of Chinese manufacturing.

Benefits of CNC Aluminum Milling in Chinese Manufacturing

The rise of CNC aluminum milling in Chinese manufacturing has transformed the industry, offering unparalleled efficiency and precision. According to a report by ResearchAndMarkets, the global CNC machine market is expected to reach $117 billion by 2025, with significant contributions from China, which holds about 30% of the market share. The use of CNC aluminum milling helps manufacturers reduce material wastage by up to 30%, ultimately saving costs and resources. This efficiency is vital for maintaining competitiveness in a rapidly evolving global market.

One of the key benefits of CNC aluminum milling is its ability to produce complex parts with high accuracy. With tolerance levels as tight as ±0.005 mm, manufacturers can create intricate designs that would be impossible with traditional machining methods. This precision not only enhances the quality of products but also shortens lead times. A survey published by Statista indicates that companies equipped with advanced CNC machines have seen their production speeds increase by up to 50%.

Tip: When selecting a CNC aluminum milling machine, consider investing in models with advanced automation features. This not only optimizes production but also minimizes the risk of human error. Moreover, regular maintenance of CNC machines can significantly extend their lifespan and ensure consistent output quality.

Top CNC Aluminum Milling Machine Brands to Consider

When considering the best CNC aluminum milling machines, it's essential to focus on top brands that demonstrate innovation, reliability, and strong performance. The landscape of CNC machining is rapidly evolving, with several key players driving advancements in this sector. These brands not only offer cutting-edge technology but also provide a wide range of machines suitable for various levels of experience—from hobbyists to large-scale manufacturers. Investing in high-quality CNC milling machines can significantly enhance productivity and accuracy in aluminum fabrication, making them a vital asset for businesses.

Moreover, recent trends indicate a growing demand for tailored CNC projects, making the selection of the right milling machine even more crucial. As the market evolves, the capability to execute precision tasks efficiently transforms into a competitive advantage. Whether you're prototyping intricate components or handling mass production, the right CNC aluminum milling machine can unlock creative potential and profitability in your CNC business. Engaging with reputable brands ensures access to advanced features, support, and the necessary tools to stay ahead in this developing industry.

Unleashing the Power of Chinese Manufacturing with the Best CNC Aluminum Milling Machines

| Machine Model | Spindle Power (HP) | Max RPM | Table Size (mm) | Weight (kg) | Price (USD) |

|---|---|---|---|---|---|

| Model A | 10 | 12000 | 800x400 | 1500 | 25000 |

| Model B | 15 | 10000 | 1000x500 | 2000 | 35000 |

| Model C | 12 | 11000 | 900x400 | 1800 | 28000 |

| Model D | 20 | 8000 | 1200x600 | 2500 | 45000 |

Tips for Optimizing Your CNC Milling Processes for Maximum Efficiency

In the realm of CNC milling, optimizing machining processes is crucial for achieving maximum efficiency and productivity. One effective approach is the incorporation of robotic systems that can automate the loading and unloading of materials and workpieces. This not only reduces manual labor but also minimizes risks associated with handling heavy or bulky components, allowing operators to focus on more strategic tasks.

Moreover, utilizing real-time data analytics can significantly enhance the CNC machining process. By monitoring parameters such as tool life and surface quality in real time, manufacturers can identify potential issues before they escalate into costly downtime due to tool breakages or premature replacements. This proactive management facilitates a smoother workflow and boosts overall production efficiency. Additionally, advanced techniques like machine learning can assist in optimizing machining parameters, ensuring precision in complex processes, such as those involved in manufacturing compressor blades, which directly impact their performance. Integrating these technologies will empower manufacturers to achieve a more streamlined and effective CNC milling process.