Mastering Quick Turn CNC Machining: Tips for Optimal Production and Efficiency

In the competitive landscape of modern manufacturing, mastering quick turn CNC machining has become essential for companies aiming to optimize production and efficiency. According to a report by MarketsandMarkets, the global CNC machining market is projected to reach USD 100 billion by 2025, highlighting the increasing demand for precision and rapid turnaround times. Quick turn CNC machining allows manufacturers to reduce lead times significantly while maintaining high-quality standards, making it an invaluable asset in industries such as aerospace, automotive, and electronics. In fact, a study by Deloitte indicates that companies employing advanced CNC techniques can improve overall productivity by up to 30%. As organizations strive to meet customer expectations for faster delivery without compromising quality, enhancing expertise in quick turn CNC machining is crucial for staying ahead in today’s fast-paced market.

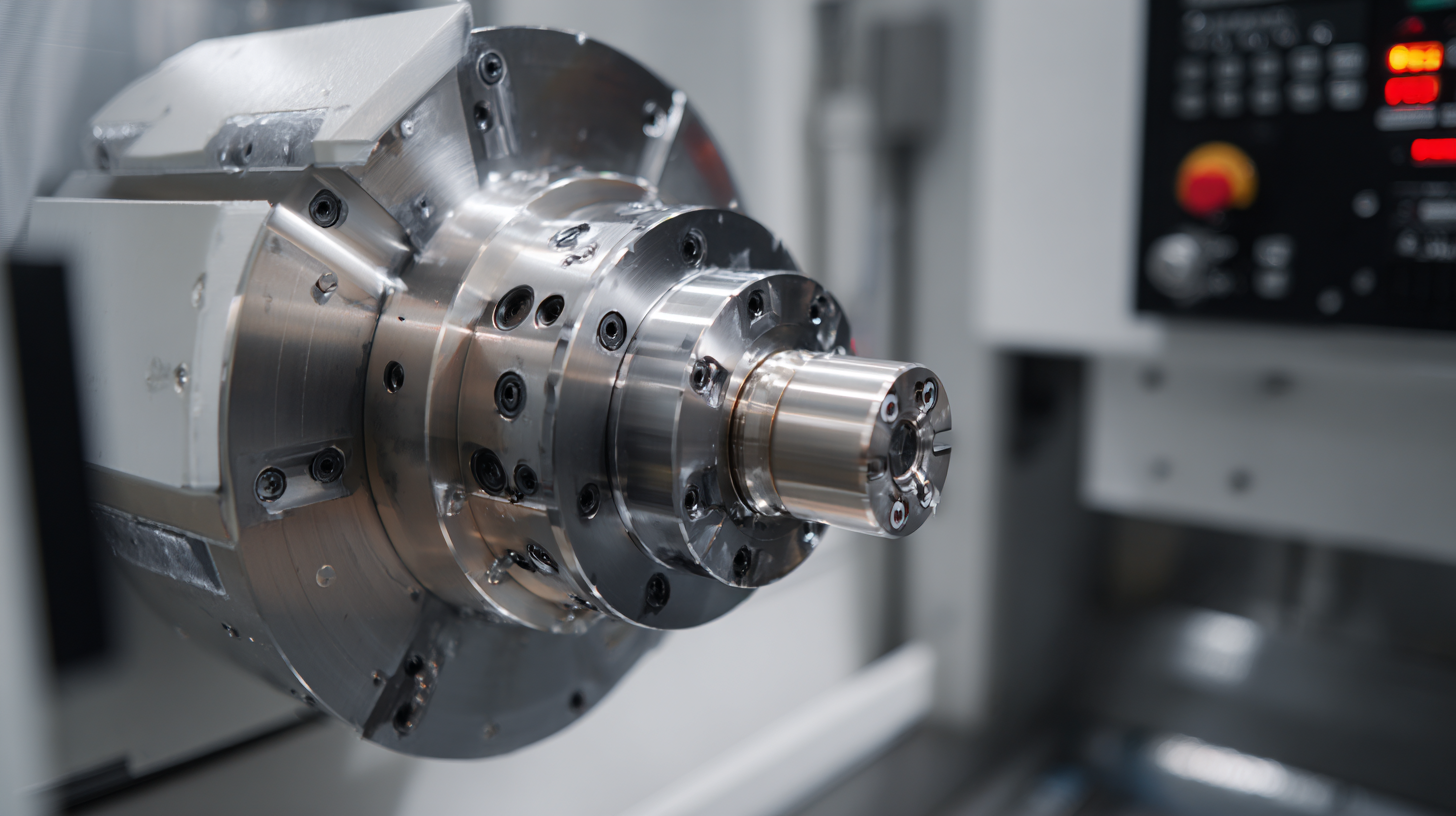

Understanding CNC Machining Fundamentals for Quick Turn Projects

Understanding the fundamentals of CNC machining is essential for optimizing quick turn projects. CNC, or Computer Numerical Control, allows for precise automation in manufacturing processes, which significantly enhances production speed and accuracy. One of the key components of successful CNC machining is recognizing the role of programming and tool selection. Efficiently written G-code programs directly influence the machine's performance and outcome of the final product. Additionally, selecting the right tools, including end mills and drills, tailored to the specific materials being worked on, contributes greatly to overall efficiency and product quality.

Moreover, comprehending the mechanics of cutters, feeds, and speeds can dramatically affect machining time and surface finish. Using appropriate feeds and speeds specific to the material not only increases productivity but also extends tool life, reducing costs in the long run. Quick turn projects often require a delicate balance between rapid output and high-quality standards. By mastering the fundamental principles of CNC machining, manufacturers can streamline their processes, achieve optimal production rates, and respond swiftly to market demands while maintaining high precision.

Choosing the Right Materials for Fast and Efficient CNC Machining

Choosing the right materials is crucial for achieving optimal production and efficiency in quick turn CNC machining. Different materials exhibit varying properties that can significantly impact machining speed, tool wear, and overall finish quality. For example, aluminum alloys are often favored for their excellent machinability and light weight, enabling faster processing and reduced tool strain. Conversely, materials like titanium, while offering high strength and durability, may require more intricate machining setups due to their toughness, which can slow down production rates.

Additionally, considering material characteristics such as thermal conductivity and hardness is essential in selecting the right option for your project. Materials with lower thermal conductivity can lead to overheating of the cutting tools, while harder materials may demand more robust tools and slower speeds, ultimately affecting efficiency. By carefully assessing project requirements and aligning them with suitable materials, manufacturers can enhance their CNC machining processes, reducing lead times and improving overall output without compromising quality.

Mastering Quick Turn CNC Machining: Tips for Optimal Production and Efficiency - Choosing the Right Materials for Fast and Efficient CNC Machining

| Material Type | Machinability Rating | Typical Applications | Cost per kg (USD) | Lead Time (Days) |

|---|---|---|---|---|

| Aluminum 6061 | 8/10 | Aerospace, Automotive Parts | 3.00 | 5 |

| Stainless Steel 304 | 7/10 | Food Processing, Medical Devices | 4.50 | 10 |

| Acrylic | 9/10 | Signage, Display Cases | 2.00 | 3 |

| Titanium Grade 5 | 6/10 | Aerospace, Marine Applications | 20.00 | 15 |

| Polycarbonate | 8/10 | Safety Glasses, Automotive | 3.50 | 4 |

Setting Up Your CNC Machine for Optimal Speed and Precision

Setting up your CNC machine for optimal speed and precision is crucial in today's fast-paced manufacturing environment. By fine-tuning various parameters, operators can achieve not only higher productivity but also enhanced accuracy in machining processes. Ensuring that the machine's calibration is precise reduces the likelihood of errors, which can lead to costly reworks. Regular maintenance and software updates play an essential role in maintaining the performance and reliability of CNC systems.

Incorporating advanced tools and techniques can further optimize production efficiency. Utilizing digital manufacturing technologies allows manufacturers to seamlessly transition from conventional methods to automated solutions. This shift not only reduces operational costs but also aligns with the increasing demand for environmentally friendly practices. By harnessing the capabilities of high-precision CNC machines, businesses can meet the rigorous demands of accuracy while improving overall throughput, ultimately leading to a competitive advantage in their respective industries.

Implementing Effective Workflows to Reduce Downtime and Boost Output

Effective workflows are essential in the realm of CNC machining,

especially as industries face increasing pressure to enhance production efficiency and minimize downtime.

According to a recent report by the Association for Manufacturing Technology (AMT),

optimizing workflows can lead to a significant reduction in machine downtime by up to 40%.

This enhancement not only maximizes the use of CNC machines but also streamlines operations, allowing manufacturers to

respond more rapidly to market demands.

One of the key strategies to boost output includes the implementation of real-time monitoring systems

that provide insights into machine performance and production bottlenecks. A study by McKinsey Global Institute

highlights that manufacturers utilizing advanced analytics saw overall productivity improvements of 20-30%.

By implementing effective communication tools between operators and machines, companies can quickly identify issues,

perform corrective actions, and ensure a seamless flow of production, thereby increasing the overall efficiency of the operation.

Integrating these technologies not only enhances productivity but also fosters a proactive maintenance culture,

which drastically reduces unplanned downtimes.

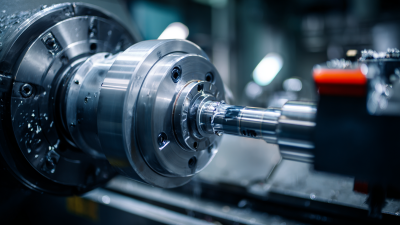

Optimizing Tool Selection and Maintenance for Quick Turn CNC Success

When it comes to quick turn CNC machining, optimizing tool selection is crucial for enhancing production efficiency. Choosing the right tools can significantly reduce downtime and improve the quality of the finished product. It's essential to assess the materials being machined and understand their specific requirements, as different materials may require specialized tooling. Additionally, selecting high-quality tools that offer durability and precision will not only enhance the machining process but also extend the lifespan of the tools, making them more cost-effective in the long run.

Equally important is the maintenance of these tools. Regular maintenance practices, such as proper cleaning, routine inspections, and timely replacements, can prevent unexpected failures and prolong tool life. Implementing a proactive maintenance schedule helps identify wear and tear before it impacts production. Moreover, ensuring that tools are correctly calibrated and stored will maintain their performance efficiency. By focusing on both selection and maintenance, manufacturers can pave the way for successful quick turn CNC operations, maximizing both productivity and product quality.

Mastering Quick Turn CNC Machining: Production Efficiency by Tool Type

Related Posts

-

5 Secrets to Finding the Best Quick Turn CNC Machining Services

-

Maximizing Value: How Exceptional After-Sales Service and Low Repair Costs in Best Rapid CNC Machining Set You Apart

-

5 Compelling Reasons Why Best Rapid CNC Machining Is Essential for Your Business Success

-

Navigating the Future: How Best Rapid CNC Machining Will Shape Industry 2025 Trends

-

5 Reasons Why Rapid CNC Machining is Your Best Option for Global Sourcing

-

Discover China’s Leading CNC Metal Milling Machines: Global Sales Surge with Quality Assurance