How to Master the Art of Aluminum Machining for Precision Engineering

In the rapidly evolving landscape of precision engineering, mastering aluminum machining has become increasingly vital for manufacturers seeking competitive advantage. According to the latest industry reports, the global aluminum machining market is projected to reach USD 7.5 billion by 2027, growing at a CAGR of 5.2% from 2020 to 2027. This growth is largely driven by the material's lightweight properties, corrosion resistance, and excellent machinability, making it a preferred choice across various sectors including aerospace, automotive, and electronics. As industries demand higher precision and efficiency, understanding the intricacies of aluminum machining techniques not only enhances product quality but also optimizes overall production processes. This guide delves into the essential strategies and best practices for mastering aluminum machining, equipping engineers and manufacturers with the tools necessary to excel in this vital aspect of modern manufacturing.

Understanding the Fundamentals of Aluminum Properties for Machining Success

Aluminum is a widely used material in precision engineering due to its excellent machinability and lightweight characteristics. Understanding the fundamental properties of aluminum is crucial for successful machining. Aluminum's inherent softness allows for easier cutting, but it also presents challenges such as galling and chip formation. Engineers must select the right tools and cutting parameters to optimize performance and maintain tolerances.

Aluminum is a widely used material in precision engineering due to its excellent machinability and lightweight characteristics. Understanding the fundamental properties of aluminum is crucial for successful machining. Aluminum's inherent softness allows for easier cutting, but it also presents challenges such as galling and chip formation. Engineers must select the right tools and cutting parameters to optimize performance and maintain tolerances.

Another key aspect of aluminum machining is its thermal properties. Aluminum dissipates heat quickly, reducing the risk of overheating during machining processes. However, this property also means that it's imperative to control the machining environment to prevent issues like warping or dimensional changes. Employing appropriate coolant and lubrication methods can mitigate these risks and improve finish quality. By mastering these fundamental properties, engineers can enhance their machining strategies, ensuring precision and efficiency in their projects.

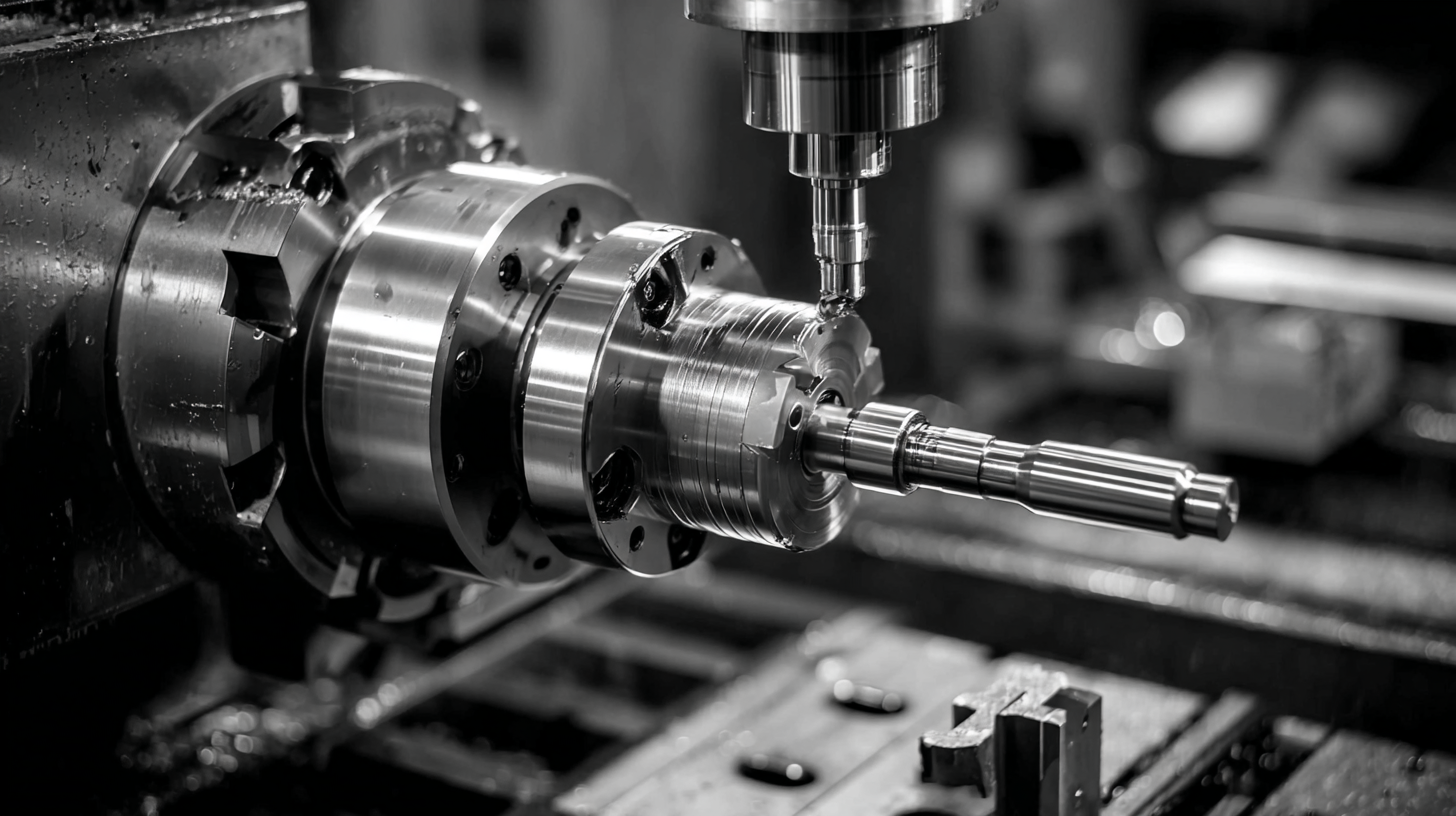

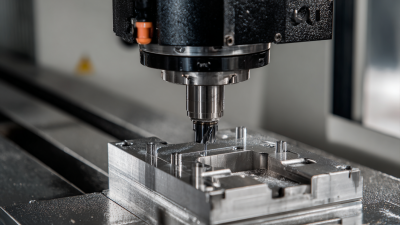

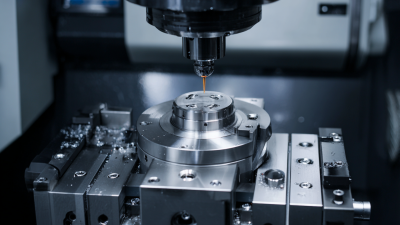

Choosing the Right Tools and Equipment for Precision Aluminum Machining

When it comes to precision aluminum machining, selecting the right tools and equipment is paramount. The intricate nature of aluminum components, especially in sectors like semiconductor manufacturing, demands a careful balance between speed and accuracy. High-quality cutting, grinding, and polishing equipment play a crucial role in achieving the required tolerances and surface finishes. An understanding of the specific characteristics of aluminum, such as its thermal properties and work-hardening tendencies, can guide machinists in making informed choices about tooling materials and geometries.

Recent trends in the industry highlight a focus on localized sourcing of materials for machining equipment, addressing the demand for advanced manufacturing solutions. Investing in reliable and precision-engineered tools enhances the efficiency of the machining process, providing a competitive edge in the rapidly evolving landscape of precision engineering. Moreover, the shift towards domestic production of essential components signifies a potential reduction in lead times and cost efficiencies, making it a critical consideration for professionals engaged in aluminum machining. By equipping themselves with the right tools and staying updated on market trends, machinists can significantly improve their operational outcomes in precision engineering projects.

How to Master the Art of Aluminum Machining for Precision Engineering

| Tool/Equipment | Type | Application | Material Compatibility |

|---|---|---|---|

| CNC Milling Machine | Milling | Complex shapes | Aluminum alloys |

| Lathe Machine | Turning | Cylindrical parts | Aluminum |

| Band Saw | Cutting | Straight cuts | Aluminum sheets |

| Drill Press | Drilling | Holes in material | Aluminum |

| Surface Grinder | Grinding | Finishing surfaces | Aluminum |

Mastering Techniques for Efficient Aluminum Cutting and Shaping

Efficient aluminum cutting and shaping require a comprehensive understanding of both the material properties and the machining techniques involved. Aluminum is a lightweight metal with excellent machinability, making it a popular choice in precision engineering. To master the art of aluminum machining, operators must focus on selecting the appropriate tooling. High-speed steel and carbide tools are commonly used, with specific geometries designed to handle the unique challenges posed by aluminum, such as chip deformation and heat build-up.

Moreover, optimizing machining parameters is crucial for achieving precision. This includes careful control of cutting speeds, feed rates, and coolant application. A faster spindle speed may enhance surface finish and reduce tool wear, while adequate lubrication helps dissipate heat and prevents built-up edge. Additionally, utilizing techniques such as climb milling can provide better surface quality and prolong tool life, leading to more efficient machining operations. By honing these techniques and understanding the specific requirements for aluminum, precision engineers can achieve outstanding results in their projects.

Aluminum Machining Efficiency Comparison

This chart compares the efficiency of different aluminum machining techniques based on the removal rate (mm³/min) and surface finish (Ra μm).

Implementing Quality Control Measures to Ensure Machining Accuracy

Implementing quality control measures in aluminum machining is critical to achieving precision engineering standards. According to a report by the American Society for Precision Engineering, tolerances of ±0.005 inches are standard in high-precision applications, making stringent quality control essential. Regular inspections and using advanced measurement tools such as coordinate measuring machines (CMM) help ensure that the machined parts fall within these tolerances, thus reducing scrap rates and improving overall production efficiency.

Moreover, integrating statistical process control (SPC) techniques can significantly enhance machining accuracy. A study published in the Journal of Manufacturing Science and Engineering found that facilities employing SPC methods saw a 20% reduction in machining variations. Techniques such as control charts and process capability analysis help in monitoring and controlling the machining process, allowing for timely adjustments before defects occur. Implementing these quality control measures not only ensures adherence to engineering specifications but also fosters a culture of continuous improvement within manufacturing processes.

Exploring Advanced Technologies in Aluminum Machining for Precision Engineering

The advancement of technologies in aluminum machining has revolutionized precision engineering, enabling manufacturers to achieve unparalleled accuracy and efficiency. Modern machining techniques, such as CNC (Computer Numerical Control) milling and turning, utilize advanced software and automated machinery. These innovations allow for the precise shaping of aluminum parts, ensuring tight tolerances and complex geometries that meet the stringent demands of various industries. Furthermore, the integration of smart manufacturing technologies, like IoT (Internet of Things) sensors, enhances real-time monitoring and control, thereby improving quality and reducing waste.

Another significant trend in aluminum machining is the adoption of cutting-edge tooling materials and coatings. High-performance carbide tools and specialized coatings, such as TiAlN (Titanium Aluminum Nitride), increase tool longevity and enhance cutting performance while minimizing friction and thermal deformation. This advancement not only extends tool life but also improves surface finish and reduces the need for secondary processes. By leveraging these advanced technologies, precision engineers can optimize their machining operations, delivering high-quality aluminum components that meet the ever-evolving needs of modern manufacturing.

Related Posts

-

Unleashing the Power of Chinese Manufacturing with the Best CNC Aluminum Milling Machines

-

The Future of Advanced Aluminum Milling Machines in Modern Manufacturing

-

Top Strategies for Optimizing Metal Cutting CNC Processes for Enhanced Efficiency

-

7 Best Practices for Precision CNC Machining: Achieving 99.9% Accuracy in Manufacturing

-

Navigating the Future: How Best Rapid CNC Machining Will Shape Industry 2025 Trends

-

Discover World-Class Manufacturing: The Best Aluminum CNC Machines from China's Premier Factory