Exploring Innovative Applications of Brass CNC Machining in Modern Design

In recent years, the utilization of brass CNC machining has gained significant traction in modern design, owing to its versatility and precision. According to a report by MarketsandMarkets, the global CNC machining market is expected to grow from $63.8 billion in 2020 to $100.3 billion by 2025, highlighting the increasing reliance on such advanced manufacturing techniques across various industries. Brass, known for its machinability and corrosion resistance, plays a pivotal role in applications ranging from architectural fittings to intricate electronic components.

This innovative approach not only optimizes material usage but also enhances design possibilities, allowing for intricate patterns and complex geometries. As designers and engineers continue to explore the potential of brass CNC machining, the integration of this technology promises to redefine manufacturing standards and boost efficiency in product development.

Innovative CNC Machining Techniques Contributing to Enhanced Brass Design Aesthetics

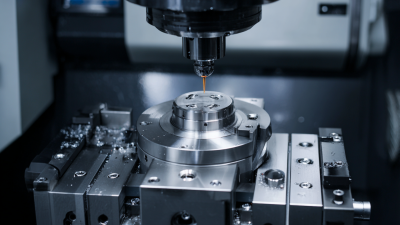

The integration of innovative CNC machining techniques in brass design is revolutionizing the aesthetics of modern creations. As designers seek to enhance visual appeal while maintaining functionality, CNC machining allows for intricate detailing and precision that was once difficult to achieve. The capabilities of these advanced techniques enable the production of unique textures and patterns, elevating the overall design of brass components. This interplay of craftsmanship and technology is ushering in a new era of design where aesthetics and practicality go hand in hand.

In the realm of home design, the application of CNC machining is evident in items such as safety grill gates that not only focus on security but also enrich the visual landscape of residential spaces. By utilizing these innovative machining methods, designers can create stunning gate designs that serve as both protective barriers and artistic statements. This fusion of security with elegance exemplifies how modern technology can significantly contribute to improved design aesthetics, allowing brass to shine as a versatile and visually appealing material in various applications.

Innovative Applications of Brass CNC Machining in Modern Design

This chart illustrates the percentage of innovative applications of Brass CNC machining techniques across various design fields, emphasizing their contribution to enhancing design aesthetics.

Evaluating the Cost Efficiency of Brass CNC Machining Versus Traditional Methods

CNC machining has revolutionized the manufacturing landscape, particularly in the realm of brass components. When evaluating the cost efficiency of brass CNC machining compared to traditional methods, it’s evident that CNC machining can often reduce production costs in the long run. While the initial investment in CNC machinery can be significant, the precision and speed offered by this technology minimize material waste and labor costs, leading to overall savings when producing complex designs.

**Tips:** Consider the long-term benefits when investing in CNC machining. Analyzing the total cost of ownership, including maintenance and potential energy savings, can provide a clearer picture of overall efficiency.

Moreover, CNC prototyping allows for rapid iteration. Unlike traditional machining, which may require extensive setup and tooling changes, brass CNC machining can adapt quickly to design changes without incurring high costs or delays. This flexibility is particularly beneficial for projects requiring customization or small batch production runs.

**Tips:** Always prototype with CNC to mitigate risks of costly errors in large production runs, ensuring that designs are optimized before full-scale manufacturing begins.

Impact of Precision CNC Machining on Brass Component Performance in Modern Applications

Precision CNC machining has become a cornerstone in the production of brass components, significantly enhancing their performance across various modern applications. The intricate and refined capabilities of CNC technology allow for the creation of complex geometries and tight tolerances that traditional machining methods cannot achieve. This precision directly influences the reliability and durability of brass components, making them indispensable in industries such as aerospace, automotive, and electronics. By utilizing CNC machining, designers can explore innovative applications that enhance both aesthetics and functionality, leading to advancements in the overall design of products.

Furthermore, the advancements in machining techniques, including those observed in processes like Wire Electrical Discharge Cutting (WEDC), offer insights into improving surface integrity for materials like titanium alloys. Such innovations can similarly impact brass, where the quality of surface finish can dictate the performance characteristics, such as wear resistance and corrosion resistance. The continuous evolution of precision machining technologies ensures that brass components not only meet but exceed the demands of modern design, thereby contributing to enhanced performance and longevity in critical applications.

Integrating Smart Technologies in Brass CNC Machining for Enhanced Production Efficiency

The integration of smart technologies in brass CNC machining is revolutionizing production efficiency across various industries. According to a report by MarketsandMarkets, the global smart manufacturing market is expected to grow from $236.7 billion in 2020 to $384.8 billion by 2025, which indicates a compound annual growth rate (CAGR) of 10.3%. This shift towards smarter factories is facilitating the adoption of advanced analytics, IoT, and automation in machining processes, allowing manufacturers to optimize operations and reduce downtime significantly.

Implementing machine learning algorithms into CNC machining not only enhances predictive maintenance but also improves the precision and quality of brass components. A study published in the Journal of Manufacturing Science and Engineering highlights that incorporating data-driven insights into the machining operations can increase production speeds by up to 30%. When combined with brass's exceptional mechanical properties and aesthetic appeal, these smart technologies enable designers to push the boundaries of modern design while maintaining high efficiency and sustainability in production processes. The blend of innovation and tradition positions brass CNC machining as a key player in the ongoing evolution of industrial manufacturing.

Case Studies: Successful Implementation of Brass CNC Machining in Contemporary Industries

Brass CNC machining has been revolutionizing various contemporary industries, showcasing its versatility and precision in modern design applications. For instance, in the consumer electronics sector, manufacturers are increasingly using brass components in their designs due to brass's excellent machinability and aesthetic appeal. A recent report indicated that the global CNC machining market is expected to reach USD 100 billion by 2026, growing at a CAGR of 6.2%. This growth is fueled by an increasing demand for high-quality machined components in various fields, including automotive and aerospace engineering.

One notable case study highlights its successful implementation in the automotive industry. A leading car manufacturer recently adopted brass CNC machining for producing intricate engine components. This decision significantly enhanced their manufacturing efficiency, reducing production costs by approximately 20%. Additionally, the durability and corrosion resistance of brass improved the overall longevity of the components, which is crucial in automotive applications. These examples underscore the importance of innovative machining techniques and materials in achieving superior design and functionality in today’s competitive market.

Related Posts

-

How to Choose the Best Brass CNC Components for Your Manufacturing Needs: A Comprehensive Guide

-

How to Choose the Best CNC Machine for Your Business Needs

-

5 Compelling Reasons Why Best Rapid CNC Machining Is Essential for Your Business Success

-

How to Achieve Fast Precision with Best Quick Turn Machining Techniques

-

7 Best Practices for Precision CNC Machining: Achieving 99.9% Accuracy in Manufacturing

-

How to Choose the Right Aluminum CNC Machine for Your Business Needs