2025 How to Choose the Fast CNC Machine for Your Manufacturing Needs

In the rapidly evolving landscape of manufacturing, choosing the right equipment can significantly impact efficiency and productivity. As industries strive for precision and speed, the demand for fast CNC machines has seen a remarkable surge. Renowned expert in CNC technology, Dr. Emily Turner, notes, "In today's market, the ability to automate and accelerate production processes through fast CNC machinery is not just an advantage—it's a necessity." This insight underscores the importance of understanding the capabilities and specifications of fast CNC machines when making a selection for your manufacturing needs.

Navigating the multitude of options available can be overwhelming. As manufacturers seek to optimize their operations, knowing the key factors that distinguish fast CNC machines is crucial. Speed, accuracy, and reliability are among the primary considerations that can drive improved outcomes in production lines. With advancements in technology, fast CNC machines are becoming increasingly accessible, but their features can vary significantly from one model to another.

Ultimately, the choice of a fast CNC machine should align with specific production requirements and workflows, leading to enhanced operational capacity. By emphasizing efficiency and technological advancements, businesses can remain competitive and meet the demands of an ever-changing manufacturing landscape.

Understanding CNC Machines: Types and Capabilities

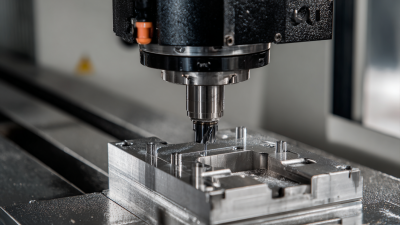

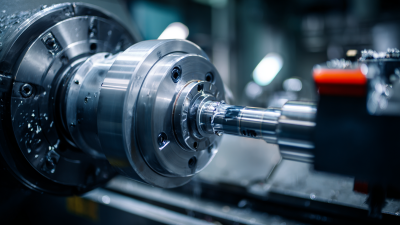

When considering a CNC (Computer Numerical Control) machine for your manufacturing needs, it’s crucial to understand the various types and capabilities available. CNC machines come in different forms, such as milling machines, lathes, routers, and plasma cutters, each designed for specific applications.

Milling machines, for example, are versatile and can handle a plethora of materials ranging from metals to plastics. Lathes are ideal for producing cylindrical parts while routers excel at high-speed cutting for intricate designs.

Tips: Assess the materials you'll be working with before selecting a CNC machine. Consider the specific geometries and tolerances required for your projects. This initial evaluation will help ensure that you choose a machine capable of meeting those demands without unnecessary operational challenges.

Another key aspect to consider is the machine's capabilities, including speed, precision, and the size of the work area. Advanced CNC machines offer high-speed capabilities with remarkable precision, crucial for tasks that require tight tolerances. Additionally, the size of the machine's work area plays a vital role in determining the size of the materials you can process.

Tips: Research the feed rate and spindle speed specifications of potential CNC machines, as these factors directly impact productivity. Additionally, evaluating the control software is essential; user-friendly interfaces can significantly enhance workflow efficiency and programming simplicity.

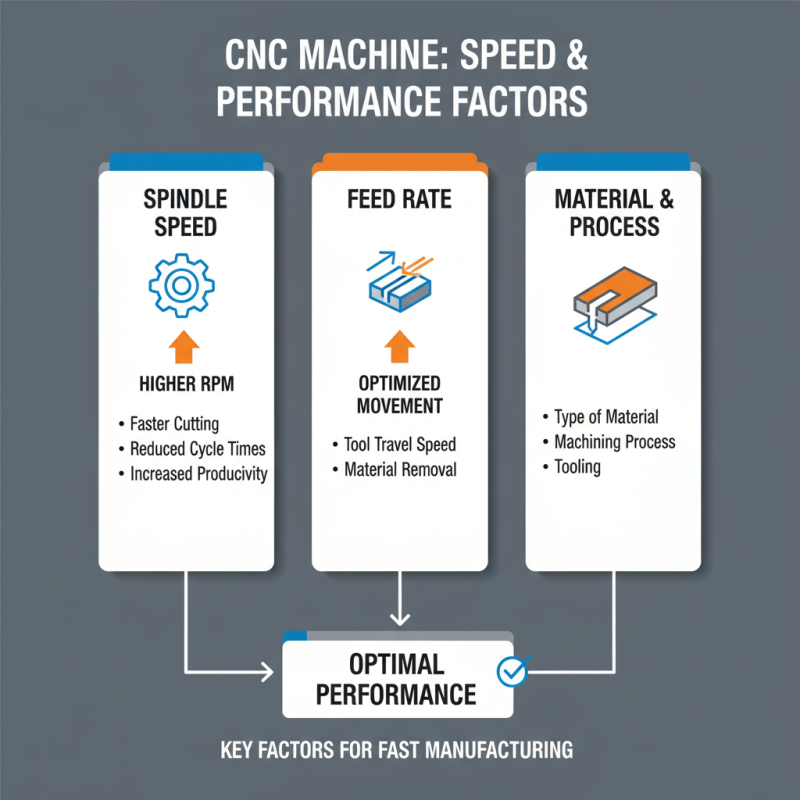

Key Factors Influencing CNC Machine Speed and Performance

When selecting a CNC machine for fast manufacturing, several key factors influence both speed and overall performance. First and foremost is the spindle speed, which significantly affects how quickly a CNC machine can operate. Higher spindle speeds enable faster cutting and milling operations, reducing cycle times and increasing productivity. Additionally, the feed rate, which determines how quickly the cutting tool moves across the material, plays a critical role. Optimizing both spindle speed and feed rate according to the material type and machining process is essential for achieving optimal performance.

Another important factor is the machine's rigidity and weight, as these directly impact stability during operations. A stable setup minimizes vibrations, which can lead to improved accuracy and faster machining times. Furthermore, advanced control systems and software capabilities also influence performance. Modern CNC machines equipped with efficient software can better manage tool paths and adapt to varying conditions during operation, leading to time savings and enhanced precision. By considering these factors, manufacturers can make informed decisions when choosing a CNC machine that meets their speed and performance requirements.

Assessing Your Manufacturing Requirements for CNC Selection

When choosing a CNC machine for your manufacturing needs, the first step is to assess your specific manufacturing requirements. Factors such as production volume, material types, and desired precision play crucial roles in making the right decision. According to a report by the International Federation of Robotics, the adoption of CNC technology has surged by over 70% in the last five years, illustrating its vital role in modern manufacturing. Companies that take the time to evaluate their machining needs not only enhance efficiency but also reduce operational costs significantly.

Tips: Define the components of your production process clearly. Consider whether you need a machine that can handle a diverse range of materials or one that excels in high-speed production for metal components. Understanding these parameters can help you narrow down your options effectively.

Additionally, it is important to gauge the machine's capabilities concerning your projected growth. A survey by SME Media revealed that 65% of manufacturers plan to expand their operations within the next three years. Investing in a CNC machine that can scale with your business will not only meet your current needs but will also accommodate future demands. Prioritizing flexibility and adaptability can result in a more sustainable manufacturing setup.

Evaluating Cost vs. Efficiency in Fast CNC Machines

When selecting a fast CNC machine, the evaluation of cost versus efficiency is crucial for optimizing manufacturing processes. According to a recent industry report by the International Society of Automation, productivity gains can exceed 20% when an efficient CNC machine is integrated into manufacturing operations. Fast CNC machines, while typically carrying higher upfront costs, can significantly reduce cycle times and increase throughput, thus balancing initial expense with long-term financial performance.

To achieve the best return on investment, manufacturers must consider not just the purchase price but also the operational costs associated with energy consumption, maintenance, and the potential for increased scrap rates. Studies indicate that machines with superior efficiency ratings can save manufacturers up to 30% in energy costs over their lifetime. Furthermore, the latest technologies in spindle speed and feed rates can enhance the material removal rates, further justifying the initial investment.

Tips: When evaluating fast CNC machines, prioritize models that offer scalability and flexibility to adapt to varying production demands. Check for compatibility with existing tools and resources within your facility, as this can minimize integration costs. Also, consider investing in training for your operators to maximize machine utilization and efficiency, as well-trained personnel can significantly reduce downtime and enhance output quality.

Comparing Leading CNC Machine Brands and Models for 2025

When selecting a fast CNC machine for your manufacturing needs in 2025, it is essential to compare leading brands and models based on several critical factors. First, evaluate the machine's speed and precision specifications. Modern CNC machines often come equipped with advanced servomotor technology, which can significantly enhance the speed of production without compromising accuracy. Look for models that feature rapid traverse rates and high feed rates, as these specifications are indicators of a machine's efficiency in handling various materials.

Additionally, consider the versatility of the CNC machine. Different models offer varied capabilities when it comes to machining different materials or performing multiple processes such as milling, turning, and engraving. A machine that can seamlessly transition between tasks can reduce downtime and improve workflow efficiency. Furthermore, examine the ease of integration with existing production lines and software. Machines that support diverse programming languages and can be easily adapted to your current systems will facilitate a smoother transition and optimal performance in your manufacturing operations.

Lastly, look into the after-sale support and warranty offered by the manufacturers. Reliable customer service is crucial for minimizing downtime and ensuring that you can quickly address any issues that may arise. By focusing on speed, versatility, and support, you can choose a fast CNC machine that meets your manufacturing needs and stands out in a competitive market.

Related Posts

-

5 Compelling Reasons Why Best Rapid CNC Machining Is Essential for Your Business Success

-

Maximizing Value: How Exceptional After-Sales Service and Low Repair Costs in Best Rapid CNC Machining Set You Apart

-

Discover China’s Leading CNC Metal Milling Machines: Global Sales Surge with Quality Assurance

-

Navigating the Future: How Best Rapid CNC Machining Will Shape Industry 2025 Trends

-

Unleashing the Power of Chinese Manufacturing with the Best CNC Aluminum Milling Machines

-

5 Secrets to Finding the Best Quick Turn CNC Machining Services