The Future of Advanced Aluminum Milling Machines in Modern Manufacturing

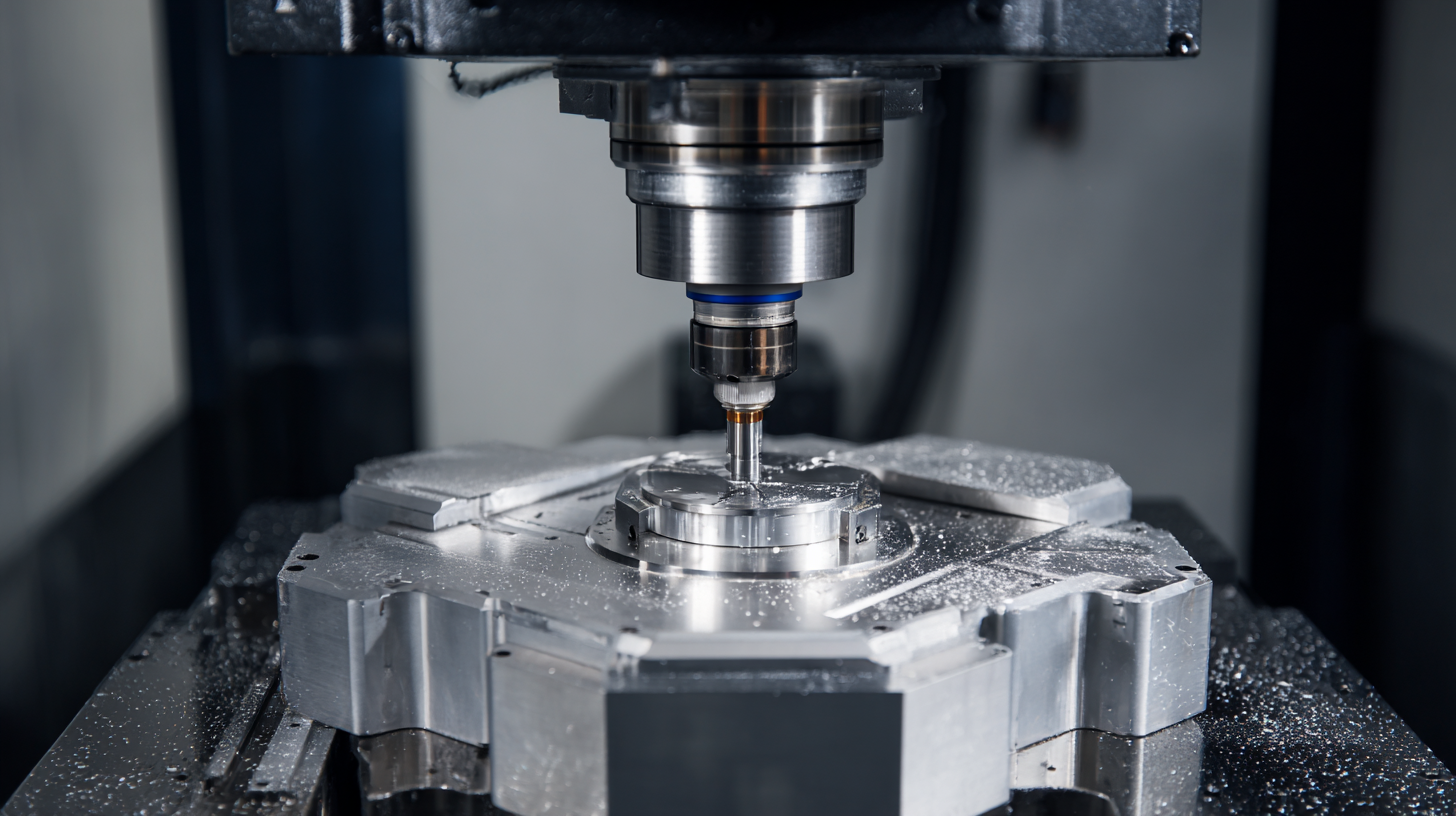

In the rapidly evolving landscape of modern manufacturing, the aluminum milling machine stands out as a pivotal tool that significantly enhances productivity and precision. As industries strive for greater efficiency and innovation, the future of advanced aluminum milling machines promises to redefine machining capabilities. With the advent of cutting-edge technologies such as automation, artificial intelligence, and improved materials, these machines are becoming more sophisticated, enabling manufacturers to achieve intricate designs and tighter tolerances with ease.

This blog will present a comprehensive checklist of key considerations and trends shaping the future of aluminum milling machines, emphasizing their role in driving success and competitiveness in the manufacturing sector. As we delve into the intricacies of this transformation, it becomes clear that understanding these advancements is essential for businesses aiming to thrive in a dynamic marketplace.

Emerging Trends in Advanced Aluminum Milling Techniques for Enhanced Efficiency

Advanced aluminum milling techniques are set to reshape modern manufacturing, reflecting a significant transition towards more efficient processes. As industries strive for sustainability, manufacturers increasingly look to integrate energy-efficient practices within their operations. Innovations in aluminum milling not only reduce energy consumption but also stream streamline workflows, enhancing productivity. This aligns with broader trends in the machine tools market, which is projected to witness substantial growth driven by burgeoning demand for advanced manufacturing solutions.

The development of lightweight materials and composites is another key trend influencing the future of aluminum milling. Such materials require precise machining capabilities, pushing the boundaries of existing milling technologies. With the projected expansion of the metal powder market and advancements in manufacturing methodologies, the efficiency and versatility of aluminum milling machines are becoming more pronounced. These trends underscore the importance of embracing cutting-edge techniques to meet the evolving demands of the automotive and construction industries, ultimately leading to improved product performance and reduced environmental impact.

Exploring Alternative Machining Processes Compatible with Aluminum milling

As industries increasingly embrace

lightweight materials,

alternative machining processes compatible with aluminum milling are gaining prominence. Traditional milling techniques often limit the flexibility and efficiency required in modern manufacturing. However, processes such as

laser cutting

and

water jet machining

present compelling alternatives that offer precision and reduced material waste. These methods not only complement aluminum milling but also open new avenues for intricate designs that are difficult to achieve through conventional techniques.

Moreover,

additive manufacturing

is emerging as a revolutionary approach that can work in tandem with aluminum milling. By layering materials, additive techniques allow for the creation of complex geometries while maintaining the favorable properties of aluminum. This synergy between

subtractive

and

additive methods enhances manufacturing capabilities, resulting in optimized production workflows. Manufacturers are beginning to explore how these integrative approaches can accelerate efficiencies, reduce turnaround times, and ultimately lead to innovative product developments in the

competitive landscape of modern manufacturing.

The Role of Automation and AI in Redefining Aluminum Milling Operations

The integration of automation and artificial intelligence (AI) in aluminum milling operations marks a revolutionary shift in modern manufacturing. With the increasing demand for precision and efficiency, manufacturers are turning to advanced milling machines equipped with intelligent systems that enhance production quality.

These automated solutions not only streamline the milling process but also minimize human error, ensuring that each component meets strict quality standards.

These automated solutions not only streamline the milling process but also minimize human error, ensuring that each component meets strict quality standards.

Furthermore, AI algorithms can analyze vast amounts of operational data in real-time, enabling predictive maintenance and smarter resource allocation. This leads to reduced downtime and higher productivity rates. As a result, the future of aluminum milling will be characterized by machines capable of autonomous decision-making and adaptive learning, ultimately driving down costs while increasing output quality. The synergy between automation and AI is poised to redefine milling operations, making them more competitive and sustainable in the ever-evolving manufacturing landscape.

Comparative Analysis: Traditional vs. Advanced Milling Alternatives for Aluminum

The landscape of aluminum milling is evolving rapidly, with traditional methods facing stiff competition from advanced milling technologies. Traditional milling machines, while reliable, often struggle with efficiency and precision when processing aluminum. They require more manual intervention, which can increase production time and labor costs. Additionally, the limitations in cutting speed and tool life can lead to less optimal outcomes for manufacturers seeking to meet high-volume demands.

In contrast, advanced milling alternatives leverage cutting-edge technology to enhance performance significantly. CNC milling machines, for instance, utilize computer numerical control to execute complex designs with high accuracy and repeatability. These machines reduce material waste and minimize the chance of human error, translating to increased productivity. Moreover, advancements in tooling materials and techniques allow for faster cutting speeds and extended tool life, ensuring that manufacturers can keep pace with the stringent requirements of modern production environments. Investing in such technologies not only streamlines the manufacturing process but also offers a competitive edge in a rapidly changing market.

Sustainability in Aluminum Milling: Exploring Eco-friendly Machine Options

As the manufacturing industry evolves, sustainability has become a key focus in the advancement of aluminum milling technologies. According to a report by the International Aluminum Institute, aluminum production currently accounts for an estimated 2% of global greenhouse gas emissions. This emphasizes the urgent need for eco-friendly machine options in the aluminum milling sector. Manufacturers are increasingly turning to advanced aluminum milling machines that not only enhance efficiency but also reduce energy consumption and waste generation.

Innovative technologies, such as hybrid machining approaches and energy-efficient drive systems, are leading the charge towards greener manufacturing processes. A survey conducted by the Machine Tool Manufacturers’ Association found that 75% of manufacturers consider sustainability a critical factor in their purchasing decisions. Machinery equipped with regenerative braking and real-time energy monitoring systems can reduce energy consumption by up to 30%, creating a more environmentally responsible manufacturing ecosystem. Furthermore, utilizing recyclable materials and minimizing coolant waste furthers the sustainability agenda, allowing companies to meet both production goals and environmental standards.

The Future of Advanced Aluminum Milling Machines in Modern Manufacturing

This chart illustrates the percentage of different eco-friendly aluminum milling machine options being adopted in modern manufacturing. It reflects the growing trend towards sustainability in the industry.