How to Achieve Fast Precision with Best Quick Turn Machining Techniques

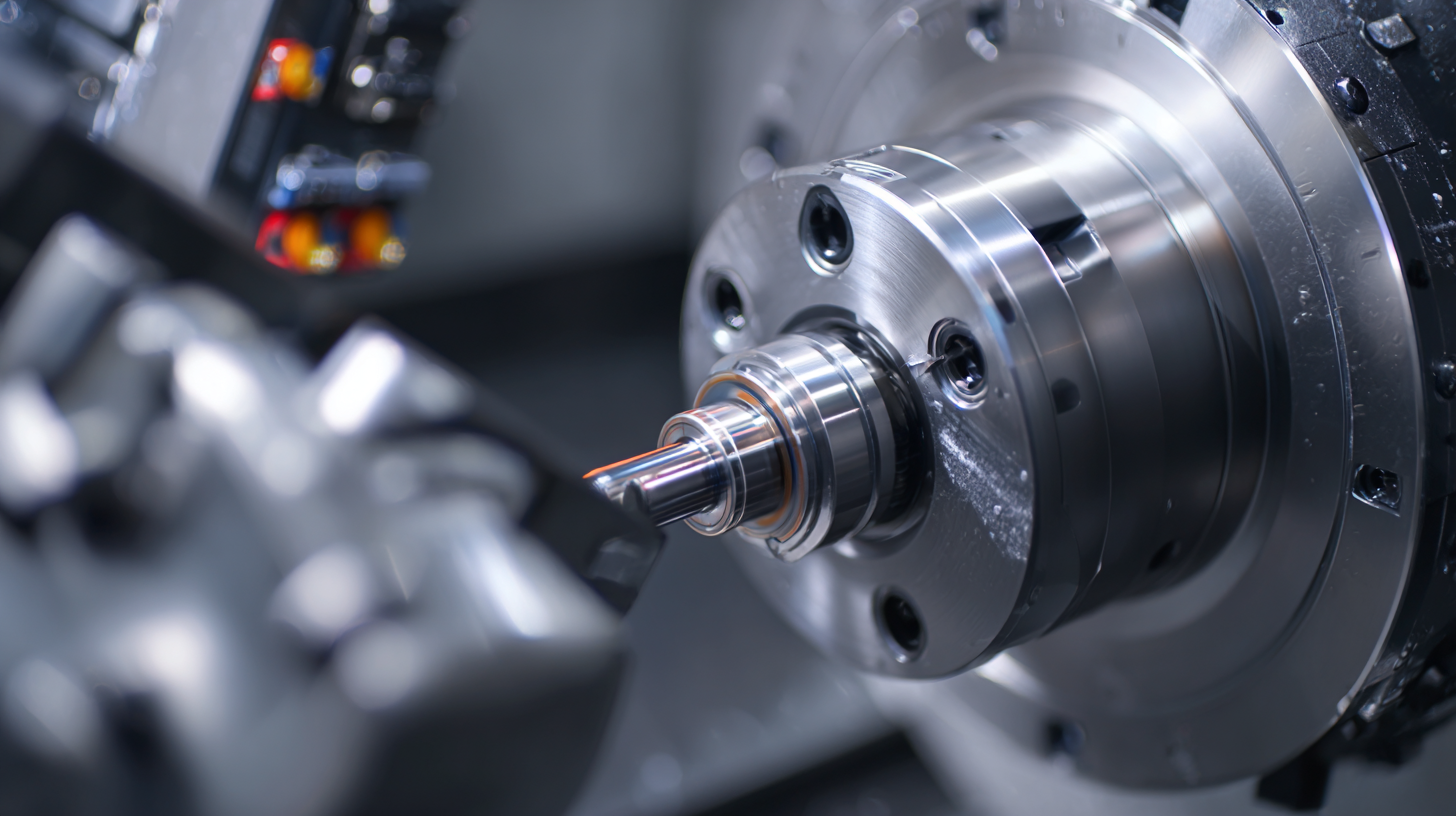

In today's highly competitive manufacturing landscape, achieving fast precision is paramount, particularly in industries that rely heavily on rapid prototyping and custom parts production.

Quick turn machining has emerged as a vital technique, enabling manufacturers to significantly reduce lead times while maintaining exceptional quality.

According to a recent industry report by SME, companies that implement advanced quick turn machining processes can reduce production time by up to 50%, ensuring quicker delivery to market.

Moreover, with the growing demand for complex geometries and high tolerances, quick turn machining provides the flexibility and efficiency needed to meet these challenges.

This blog will explore various quick turn machining techniques and offer a comparative analysis to help manufacturers choose the best approaches for their unique needs.

Quick turn machining has emerged as a vital technique, enabling manufacturers to significantly reduce lead times while maintaining exceptional quality.

According to a recent industry report by SME, companies that implement advanced quick turn machining processes can reduce production time by up to 50%, ensuring quicker delivery to market.

Moreover, with the growing demand for complex geometries and high tolerances, quick turn machining provides the flexibility and efficiency needed to meet these challenges.

This blog will explore various quick turn machining techniques and offer a comparative analysis to help manufacturers choose the best approaches for their unique needs.

Benefits of After-Sales Support in Quick Turn Machining Services

After-sales support in quick turn machining services plays a crucial role in ensuring customer satisfaction and long-term partnerships. Since the demand for rapid manufacturing continues to rise—especially in industries such as aerospace and medical devices—offering robust after-sales services can significantly differentiate a company from its competitors. According to a report by MarketsandMarkets, the global quick turn machining market is expected to reach $4.5 billion by 2025, emphasizing the need for effective support systems that can address client concerns promptly and efficiently.

One of the key benefits of after-sales support is the ability to provide timely technical assistance. Fast response times can minimize downtime and prevent production delays, which can be costly. A survey conducted by Deloitte revealed that 62% of organizations believe that effective after-sales service enhances their brand loyalty. Furthermore, providing comprehensive training and resources for customers can lead to better understanding and utilization of machined products, ultimately improving their operational efficiency. These support elements contribute not only to customer retention but also to increased referrals, reinforcing a company’s reputation in the competitive quick turn machining landscape.

Quick Turn Machining Efficiency and After-Sales Support

Understanding the Cost Implications of Machine Repairs in Fast Precision Industries

In the fast precision machining industry, understanding the cost implications of machine repairs is crucial for maintaining efficiency and competitiveness. According to a report by the Machinery Maintenance Association, up to 30% of overall manufacturing costs can be attributed to machine downtime and repair expenses. In environments where precision is key, unexpected breakdowns can lead to significant financial losses, not only due to repair costs but also lost production time.

Investing in preventive maintenance programs can reduce the likelihood of costly repairs. The Institute of Industrial Engineers highlights that proactive maintenance strategies can decrease repair costs by approximately 25% to 30%. Additionally, modern predictive analytics technologies further enhance maintenance approaches by anticipating potential failures before they occur, allowing firms to make informed decisions about when to repair or replace machinery. This shift from reactive to predictive maintenance is revolutionizing how fast precision sectors manage their budgets and resources, ensuring that they remain agile and cost-effective in a competitive landscape.

Enhancing Customer Satisfaction through Effective After-Sales Strategies

Effective after-sales strategies play a crucial role in enhancing customer satisfaction in the realm of quick turn machining. Once a project is completed, maintaining a solid relationship with clients ensures that they feel valued and supported.

Proactive communication is key; regular follow-ups to address any concerns or gather feedback can foster trust and transparency. By listening to customer needs and swiftly addressing issues, businesses can demonstrate their commitment to quality service, translating to long-term client loyalty.

Effective after-sales strategies play a crucial role in enhancing customer satisfaction in the realm of quick turn machining. Once a project is completed, maintaining a solid relationship with clients ensures that they feel valued and supported.

Proactive communication is key; regular follow-ups to address any concerns or gather feedback can foster trust and transparency. By listening to customer needs and swiftly addressing issues, businesses can demonstrate their commitment to quality service, translating to long-term client loyalty.

Moreover, implementing comprehensive after-sales support, such as offering maintenance services, technical assistance, or even training for clients, can significantly elevate their experience. Providing resources that empower customers to utilize the products or services effectively not only boosts their satisfaction but also positions the company as a trusted partner in their growth. This approach not only reinforces the brand's credibility but can also lead to increased referrals, further expanding the customer base. In a competitive market, investing in after-sales strategies is essential for building lasting relationships and ensuring sustained business success.

Best Practices for Reducing Maintenance Costs in Machining Operations

In the world of machining operations, reducing maintenance costs is paramount for sustaining profitability and enhancing productivity. One of the best practices to achieve this is through the implementation of predictive maintenance strategies. By utilizing advanced monitoring technologies and data analytics, companies can identify potential issues before they lead to costly breakdowns. This approach not only minimizes unplanned downtime but also extends the lifespan of machinery, ultimately leading to significant cost savings.

Another effective method for reducing maintenance expenses is to invest in high-quality tools and equipment. Although the initial investment may be higher, durable and reliable machinery often results in lower long-term maintenance costs and improved efficiency. Additionally, regular training for operators on best practices for machine care can further decrease the likelihood of operational mistakes that could lead to wear and tear. By fostering a culture of care and maintenance awareness, companies can ensure their machinery runs optimally, reducing the frequency and severity of maintenance interventions.

Leveraging Technology to Improve Repair Efficiency and Reduce Downtime

In the ever-evolving landscape of manufacturing, leveraging technology is crucial for enhancing repair efficiency and minimizing downtime. With advancements such as nanorobotics projected to reach a staggering market size of $784.7 billion by 2033, the integration of such technologies into quick turn machining offers a pathway to faster precision and improved operational outcomes. These innovations enable manufacturers to streamline maintenance processes, reducing the time machines remain offline and enhancing overall productivity.

To achieve this, it's essential to focus on implementing best practices. Regular maintenance and the use of predictive analytics can help identify potential issues before they escalate, thereby optimizing repair schedules. Additionally, investing in training for your workforce to utilize cutting-edge technologies can further boost efficiency. Automation tools and smart sensors play a pivotal role in reducing human error and ensuring that repairs are conducted swiftly and accurately, contributing to a more resilient production environment.

Moreover, adopting a culture of continuous improvement by integrating feedback from repair processes can guide future enhancements. By fostering an agile approach, companies can adapt to technological advancements and ensure they remain competitive in an increasingly complex market. Embracing these strategies will not only mitigate downtime but also empower manufacturers to maintain a high standard of quality in their output.