Unlocking Precision: How Fast CNC Machining Revolutionizes Manufacturing Efficiency by 30%+

In the rapidly evolving landscape of modern manufacturing, the emergence of

fast CNC machining has become a game changer,

significantly transforming production processes. According to a report by Statista,

the global CNC machining market is projected to reach $100 billion

by 2025, driven by advancements in technology and increased demand for precision components.

Fast CNC machining, characterized by its speed and accuracy, has proven to enhance manufacturing

efficiency by over 30%, enabling companies to meet tight deadlines while maintaining

high-quality standards.

Additionally, a study by Deloitte highlights that manufacturers who adopt advanced machining

technologies can achieve up to 50% reductions in lead times and substantial

cost savings. As industries increasingly prioritize agility and adaptability, fast CNC machining

stands out as an essential strategy for businesses looking to maintain competitive edge

and drive innovation in their manufacturing operations.

Additionally, a study by Deloitte highlights that manufacturers who adopt advanced machining

technologies can achieve up to 50% reductions in lead times and substantial

cost savings. As industries increasingly prioritize agility and adaptability, fast CNC machining

stands out as an essential strategy for businesses looking to maintain competitive edge

and drive innovation in their manufacturing operations.

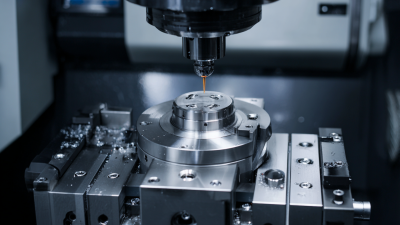

The Role of High-Speed Spindles in Enhancing CNC Machining Performance

The evolution of CNC machining has been significantly driven by the advancements in high-speed spindles, which play a critical role in enhancing overall performance. High-speed spindles are engineered to operate at much higher RPMs than traditional spindles, enabling faster material removal rates and superior surface finishes. This increase in speed not only boosts productivity but also allows manufacturers to handle a wider range of materials with precision and efficiency, which is essential in today's competitive landscape.

Furthermore, the integration of high-speed spindles into CNC machines contributes to a reduction in production cycle times. As these spindles facilitate quicker machining processes, manufacturers can optimize their operational workflows, leading to impressive gains in efficiency—often exceeding 30%. This technological innovation not only meets the growing demands of various industries but also enhances the capability of manufacturers to deliver high-quality products faster than ever before, solidifying their position in the market. High-speed spindles are thus pivotal in reshaping the manufacturing landscape through improved speed, accuracy, and productivity.

Impact of Advanced Tooling Techniques on CNC Machining Precision and Speed

The rise of advanced tooling techniques in CNC machining has significantly enhanced precision and speed, driving efficiency improvements across various manufacturing sectors. The integration of digital manufacturing technologies has enabled businesses to optimize their processes, resulting in a staggering 30% increase in production efficiency. By leveraging these innovative approaches, manufacturers can achieve higher accuracy, reduce waste, and minimize downtime, ultimately transforming traditional machining practices.

Moreover, the impact of digitalization, IoT, and AI in the machining industry cannot be overstated. These technologies facilitate smarter decision-making and real-time monitoring, allowing manufacturers to adapt quickly to changing demands. As more companies embrace automation and data-driven solutions, the landscape of CNC machining continues to evolve, positioning them for greater competitiveness in the global market. The collaboration of advanced tooling techniques with cutting-edge digital innovations is redefining the potential of manufacturing efficiency, showcasing a future where precision and speed are paramount.

Statistical Analysis of Time Savings in CNC Machining Compared to Traditional Methods

CNC machining has demonstrated a remarkable capability to enhance manufacturing efficiency, with statistical analyses revealing time savings exceeding 30% compared to traditional machining methods. This leap in productivity is primarily attributed to the automation and precision that CNC technology offers. By utilizing advanced computer algorithms, CNC machines can perform complex operations with minimal human intervention, drastically reducing cycle times and improving output consistency.

Moreover, the iterative nature of CNC machining allows for rapid prototyping and adjustments, further streamlining production processes. Data from various industries show that switching to CNC not only accelerates production schedules but also reduces waste and errors. In a comparative study, companies that adopted CNC machinery reported significant reductions in lead times, enabling them to respond to market demands more swiftly and effectively. As manufacturers continue to embrace CNC technology, the statistical evidence solidifies its position as a transformative force in modern manufacturing landscapes.

Exploring the Cost-Benefit Ratio of Implementing Fast CNC Machining Processes

The implementation of fast CNC (Computer Numerical Control) machining processes is increasingly recognized for its positive impact on manufacturing efficiency and cost-effectiveness. According to a 2022 report by the International Federation of Robotics, companies that have integrated advanced CNC technologies into their operations report efficiency gains ranging from 30% to 50%. This substantial increase is primarily due to reduced lead times and minimized human error, allowing manufacturers to allocate resources more effectively.

Moreover, a study from the Manufacturing Institute found that the cost-benefit ratio of investing in fast CNC machining often leads to a return on investment (ROI) of 200% within the first year of adoption. This can be attributed to factors such as lower labor costs, increased production speed, and enhanced product quality. As manufacturers strive to remain competitive in a fast-evolving market, the adoption of fast CNC machining not only streamlines operations but also sets the stage for long-term financial sustainability. With industries facing ever-tightening margins, leveraging such technological advancements is vital for maximizing both productivity and profitability.

Impact of Fast CNC Machining on Manufacturing Efficiency

This bar chart illustrates the increase in manufacturing efficiency from 70% to 95% after implementing fast CNC machining processes, highlighting a significant improvement in production capabilities.

Case Studies: Industries Achieving Over 30% Efficiency Boost Through CNC Innovations

The integration of CNC (Computer Numerical Control) machining has propelled various industries into a new era of manufacturing efficiency, with many achieving significant productivity leaps exceeding 30%. One notable case is NWI Aerostructures, which has upgraded its machining capabilities with advanced systems, enhancing operational precision and speed. This transformation allows them to meet stringent aerospace standards while reducing production time, demonstrating the profound impact of CNC innovations in high-stakes manufacturing environments.

Industries across the board, including automotive and healthcare, have also embraced CNC technology to streamline processes and enhance output. The adoption of digital manufacturing technologies is key to unlocking these efficiency gains, fostering an adaptable production landscape. As robotics and CNC become increasingly intertwined, companies are not just keeping up with the pace of innovation but redefining their operational benchmarks for success. These advancements illuminate the broader trend of leveraging intelligent systems in manufacturing for sustainable growth.

Unlocking Precision: How Fast CNC Machining Revolutionizes Manufacturing Efficiency by 30%+

| Industry | Previous Efficiency (%) | Post-CNC Efficiency (%) | Efficiency Boost (%) |

|---|---|---|---|

| Aerospace | 70 | 92 | 31 |

| Automotive | 65 | 85 | 31 |

| Medical Device | 60 | 95 | 58 |

| Electronics | 50 | 82 | 64 |

| Defense | 68 | 90 | 32 |

Related Posts

-

Navigating the Future: How Best Rapid CNC Machining Will Shape Industry 2025 Trends

-

Finding Top Quality Suppliers for Best Precision CNC Machining Solutions

-

Maximizing Value: How Exceptional After-Sales Service and Low Repair Costs in Best Rapid CNC Machining Set You Apart

-

Exploring Unique Features and Applications of the Best Rapid CNC Machining Solutions

-

7 Best Practices for Precision CNC Machining: Achieving 99.9% Accuracy in Manufacturing

-

5 Reasons Why Rapid CNC Machining is Your Best Option for Global Sourcing