What is Fast CNC Machining and How Does it Work?

Fast CNC machining is transforming modern manufacturing. Experts in the field point out the advantages and limitations of this technology. According to John Smith, a renowned CNC expert, "Fast CNC machining increases efficiency but can impact precision if not managed properly."

In the fast-evolving industry, speed often comes at a cost. Fast CNC machining utilizes advanced algorithms and high-speed tools to create parts quickly. However, the challenge arises in maintaining quality alongside speed. Manufacturers must strike a balance between rapid production and meticulous detail.

The choice of materials also affects the machining process. Some materials respond well to fast techniques, while others require traditional methods for quality. The landscape of fast CNC machining is complex, and constant reflection is necessary. As speed becomes the standard, the importance of precision should never be overlooked.

What is Fast CNC Machining?

Fast CNC machining is a method that enhances traditional CNC processes. It emphasizes speed without compromising accuracy. This technique is increasingly popular in industries that require rapid prototyping and production. Components can be fabricated quickly, which is crucial for meeting tight deadlines.

In fast CNC machining, advanced software and high-speed tools are employed. These tools remove material rapidly, allowing for efficient designs. However, this speed can sometimes lead to errors. Inexperienced operators may overlook small details, affecting the final product's quality. Continuous training and practice are essential to mitigate these risks.

The process also involves choosing appropriate materials. Not every material responds well to fast machining. Selecting the wrong one can lead to complications. Balancing speed and quality is a constant challenge. It's important to reflect on production methods that may need improvement for consistent outcomes.

Key Principles of CNC Machining Technology

CNC machining technology operates based on automated processes. It stands for Computer Numerical Control. This method uses precise instructions fed into a computer. From these instructions, a machine interprets and executes movements. The core principle relies on accuracy and repeatability.

Fast CNC machining enhances efficiency. As machines can operate continuously with little intervention, production rates increase significantly. However, errors still occur. Sometimes, intricate designs may lead to production flaws. This necessitates constant monitoring and adjustment. Understanding the potential for mistakes is crucial in this field.

Moreover, material choice plays a key role in machining outcomes. Different materials react differently to cutting tools and speeds. Sometimes, softer materials may require special handling to avoid issues. The balance between speed and quality requires careful thought. It’s essential to weigh the benefits against possible complications. Achieving perfection in CNC machining remains a complex task.

Advantages of Fast CNC Machining in Manufacturing

Fast CNC machining offers significant advantages in manufacturing, especially in terms of efficiency and precision. Studies indicate that CNC machining can reduce production time by up to 75% in comparison to traditional methods. This rapid prototyping capability allows manufacturers to respond quickly to market demands. A survey from the National Association of Manufacturers shows that 70% of manufacturers prioritize speed in their production processes.

In addition to time savings, fast CNC machining enhances accuracy. The process can achieve tolerances within ±0.001 inches, which is crucial for industries that demand high precision, such as aerospace and medical devices. While automation lowers human error, it doesn’t eliminate it entirely. Operators still need to check machines regularly to maintain optimal performance. According to a report by Deloitte, 58% of machine failures stem from operator oversight rather than equipment malfunction.

Furthermore, fast CNC machining is often more cost-effective in the long run. Although initial setup costs might be high, the increased production rates contribute to lower per-unit costs. A study by the Manufacturing Institute pointed out that rapid machining can lead to a 20-30% decrease in operational expenses over time. However, companies should be aware of the potential pitfalls, such as machine wear and the need for regular maintenance, which can impact profitability.

Common Applications of Fast CNC Machining

Fast CNC machining has transformed various industries by providing precise and quick manufacturing solutions. This technology is often utilized in automotive production. Car manufacturers rely on Fast CNC machining for creating complex parts. The ability to produce prototypes swiftly helps in testing designs. This results in shorter cycle times, enhancing overall efficiency.

Another significant application is in the aerospace industry. Fast CNC machining is crucial for producing lightweight components. These parts require extreme precision to ensure safety and performance. The intricate designs often present challenges. However, with advanced CNC technology, these challenges are overcome. Maintaining accuracy while speeding up production is vital.

Medical device manufacturing also benefits from this technology. Fast CNC machining allows for the creation of complex surgical instruments. The high level of detail is essential in this field. It ensures that devices work as intended. There can be mistakes with tolerances and dimensions. Continuous improvement is necessary to address these issues.

Fast CNC Machining Applications

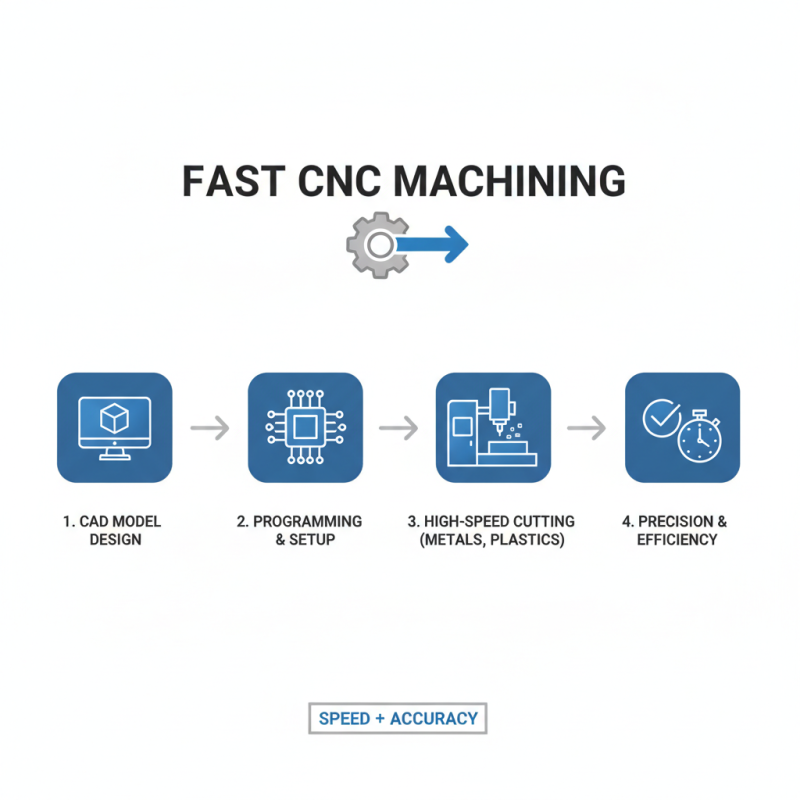

The Process of Fast CNC Machining Explained

Fast CNC machining is a precise method of manufacturing that emphasizes speed alongside accuracy. The process begins with a computer-aided design (CAD) model. This model serves as a blueprint for the machinery. Once programmed, the CNC machine starts to cut, carve, or shape materials. The materials are often metals, plastics, or composites. The machines work quickly, minimizing waste and maximizing efficiency.

During machining, operators must monitor the process closely. Mistakes can happen, leading to defects. This requires real-time adjustments, which can be a learning point. The automation aspect can sometimes create a false sense of security. Even with advanced technology, human oversight remains vital for achieving quality results. Each piece produced adds to the learning curve. Operators reflect on challenges and successes alike, improving future runs.

Quick turnaround times are beneficial. However, the need for precision never fades. Each project presents unique challenges. The balance between speed and quality can create tension. Finding that middle ground is crucial for success in fast CNC machining. This dynamic process continues to evolve, pushing boundaries and enhancing capabilities.

Related Posts

-

5 Compelling Reasons Why Best Rapid CNC Machining Is Essential for Your Business Success

-

Navigating the Future: How Best Rapid CNC Machining Will Shape Industry 2025 Trends

-

Maximizing Value: How Exceptional After-Sales Service and Low Repair Costs in Best Rapid CNC Machining Set You Apart

-

Unlocking Precision: How Fast CNC Machining Revolutionizes Manufacturing Efficiency by 30%+

-

Mastering Best Rapid CNC Machining Techniques for Global Buyers

-

2025 How to Choose the Fast CNC Machine for Your Manufacturing Needs