Ultimate Guide to Effective Steel Machining Techniques for Optimal Results

In the competitive landscape of manufacturing, achieving optimal results in steel machining is more crucial than ever. According to a report by the International Federation of Robotics, the global market for machine tools, including steel machining technologies, is expected to reach $135 billion by 2025, reflecting a compounded annual growth rate (CAGR) of 5%. This underscores the increasing demand for precision and efficiency in steel processing operations.

Effective steel machining techniques not only enhance productivity but also ensure cost-effectiveness and quality control, vital factors for businesses aiming to maintain a competitive edge. By incorporating advanced technologies and best practices, manufacturers can significantly improve their machining processes, leading to superior product outcomes and reduced operational costs.

This guide explores the key techniques and insights for mastering steel machining, so you can achieve outstanding results in your manufacturing endeavors.

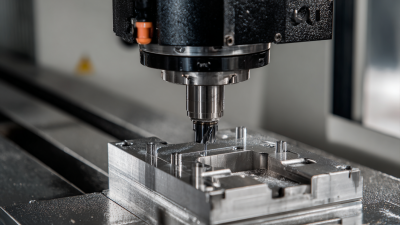

Understanding the Basics of Steel Machining: Materials and Tools You Need

When it comes to effective steel machining, understanding the basics of the materials and tools at your disposal is paramount. Steel, known for its durability and strength, comes in various grades, each suited for specific machining processes. Choosing the right type of steel, whether it's high-carbon, stainless, or alloy steel, can significantly influence the outcome of your machining tasks. Familiarizing yourself with the properties of these materials will help in selecting the appropriate machining technique, thereby enhancing both efficiency and precision.

Equally important is the selection of tools. Common tools used in steel machining include lathes, milling machines, and band saws, each designed to perform specific functions. Moreover, the choice of cutting tools—such as high-speed steel (HSS) or carbide inserts—can impact the quality of the finished product. Understanding the cutting speed, feed rate, and tool geometry is essential for optimizing performance and prolonging tool life. By mastering both the material types and the necessary tools, you can ensure that your steel machining operations yield the best possible results.

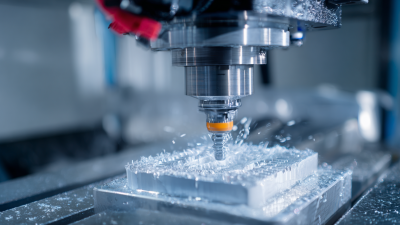

Key Techniques for Precision Steel Machining: From Turning to Milling

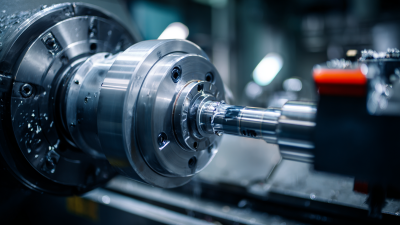

Precision steel machining is crucial in various industries, particularly in automotive and aerospace sectors, where tolerances are tight and reliability is paramount. Key techniques such as turning and milling not only enhance the accuracy of components but also improve operational efficiency. According to a report by the International Journal of Advanced Manufacturing Technology, the application of advanced CNC (Computer Numerical Control) technologies in steel machining has led to a 30% increase in productivity while reducing waste by up to 20%.

Turning, a process widely utilized for producing cylindrical parts, relies heavily on cutting tool geometry and material properties. Recent studies indicate that the optimal selection of tool materials, such as carbide and ceramic, can extend tool life by up to 50%, significantly reducing downtime and production costs. On the other hand, milling techniques, which involve rotating multi-toothed cutters, are essential for achieving complex geometrical shapes. Research from the American Society of Mechanical Engineers emphasizes that optimizing feed rates and spindle speeds can enhance surface finishes and dimensional accuracy by 25%, underscoring the importance of precision in steel machining processes.

Optimizing Cutting Parameters for Enhanced Efficiency and Quality

Optimizing cutting parameters is crucial in steel machining, as it directly influences efficiency and the quality of the finished product. According to a report by the International Journal of Advanced Manufacturing Technology, proper cut depth, feed rate, and speed can significantly enhance tool life and reduce manufacturing costs by up to 30%. Selecting the right combination of these parameters allows manufacturers to maximize productivity while maintaining high precision.

Tip: Always refer to the tool manufacturer’s guidelines when setting your cutting parameters. These guidelines are based on extensive testing and can provide a solid starting point to avoid premature tool wear.

Additionally, regular monitoring and adjustments of machining parameters can lead to substantial improvements. A study from the Society of Manufacturing Engineers reported that continuous monitoring can increase efficiency by as much as 20%, by allowing for real-time adjustments based on material behavior. Implementing intelligent machining systems that analyze these parameters can further optimize operations.

Tip: Utilize software tools that provide data analytics on cutting parameters. These can help identify trends and areas for improvement, leading to more informed decision-making in the manufacturing process.

Addressing Common Challenges in Steel Machining: Tips and Solutions

Steel machining presents unique challenges, particularly given the complexity of materials like high-speed steel, which is critical for the production of cutting tools, molds, and wear-resistant components. This type of steel, characterized by its intricate composition and high alloy content, retains remarkable hardness and wear resistance even at temperatures reaching up to 700 ℃. Understanding how to effectively work with such materials can significantly enhance the quality of machined products and improve operational efficiency.

To tackle common issues in steel machining, one must emphasize precision and proper tool selection. Utilizing advanced machining techniques and state-of-the-art equipment is essential to overcoming obstacles such as tool wear and inadequate accuracy. For instance, the burgeoning electric vehicle sector has necessitated the development of innovative solutions that streamline the machining process of components, particularly in the production of smart wiring harnesses, which face their own set of unique challenges. By adopting the right methodologies and leveraging advancements in technology, manufacturers can not only mitigate these challenges but also ensure optimal machining results that meet the rising demand in the global market.

Innovative Technologies in Steel Machining: Trends to Watch in the Industry

In the realm of steel machining, staying ahead of the curve requires a keen awareness of the latest technological innovations that are reshaping the industry. As the metal machining market is projected to expand by USD 18.43 billion from 2024 to 2028, driven by rising demands from sectors like oil and gas, the integration of Artificial Intelligence (AI) is becoming increasingly pivotal. AI is not just transforming operational efficiency but also contributing to smarter machining solutions that cater to complex engineering demands.

Moreover, the CNC (Computer Numerical Control) machine market is poised for significant growth, with its adoption of digital manufacturing technologies drastically improving productivity across various industries. Reports indicate that advanced production technologies, such as 3D printing and plasma cutting, are revolutionizing the landscape; for instance, the global plasma cutting market is anticipated to reach USD 958 million by 2030. This shift towards innovative cutting technologies facilitates more precise machining processes, pushing the boundaries of what is achievable in material specifications and design intricacies. As we delve deeper into these advancements, steel machining not only enhances its operational capabilities but also aligns with the greater trend of sustainable manufacturing, ensuring that production meets current needs without compromising future sustainability.

Ultimate Guide to Effective Steel Machining Techniques for Optimal Results

Related Posts

-

Top Strategies for Optimizing Metal Cutting CNC Processes for Enhanced Efficiency

-

10 Reasons Why the Industrial CNC Milling Machine is the Best Investment for Your Business

-

China's Premier Rapid Prototype Machining Solutions Powering Global Manufacturing Excellence

-

Unleashing the Power of Chinese Manufacturing with the Best CNC Aluminum Milling Machines

-

5 Secrets to Finding the Best Quick Turn CNC Machining Services

-

Exploring Innovative Alternatives to Best Milling Machine CNC for Global Manufacturers