Unlocking Precision: How CNC Milling Machines Revolutionize Modern Manufacturing

The rise of milling machine CNC technology represents a pivotal shift in modern manufacturing, characterized by enhanced precision and efficiency. According to a recent report by MarketsandMarkets, the CNC machining market is projected to grow from $63.51 billion in 2020 to $100.12 billion by 2026, highlighting an annual growth rate of 7.9%. This surge is driven by increasing demand for precision-engineered components across various sectors, including aerospace, automotive, and medical devices.

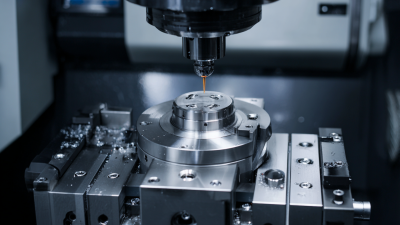

CNC milling machines, specifically, enable manufacturers to achieve intricate designs with minimal human intervention, significantly reducing production times and costs. As industries increasingly adopt automation and digital manufacturing techniques, the role of CNC milling machines becomes even more critical, shaping the future of production while setting new standards for quality and performance.

Understanding CNC Milling: The Backbone of Modern Manufacturing Efficiency

CNC milling machines have become the backbone of modern manufacturing efficiency, significantly transforming production processes across various industries. According to a report by MarketsandMarkets, the global CNC machine market is projected to reach $100.08 billion by 2025, growing at a CAGR of 7.5% from 2020. This growth can be attributed to the increasing demand for precision machining and the automation of manufacturing processes, which CNC milling provides. These machines enable manufacturers to produce complex shapes with high accuracy, minimizing waste and reducing turnaround times.

Furthermore, the integration of Industry 4.0 technologies has amplified the impact of CNC milling on manufacturing systems. A study by Deloitte indicates that manufacturers utilizing advanced CNC technologies can achieve up to 30% improvement in overall equipment efficiency (OEE). This efficiency is a result of reduced setup times, enhanced flexibility, and the ability to execute multiple operations in a single pass. By harnessing the power of CNC milling, businesses not only optimize their production capabilities but also position themselves effectively within the competitive landscape of the global market.

Impact of CNC Milling Machines on Manufacturing Efficiency

This bar chart illustrates the increasing production efficiency attributed to the adoption of CNC milling machines from 2018 to 2022. As technology advances, the effectiveness of CNC milling in modern manufacturing processes has significantly improved, enhancing overall production capabilities.

Key Advantages of CNC Milling: Precision, Speed, and Cost Reduction in Production

CNC milling machines have transformed the landscape of modern manufacturing by providing unparalleled precision, speed, and cost efficiency. According to a report by Market Research Future, the global CNC machine market is expected to reach $100 billion by 2024, underscoring the growing reliance on CNC technology in various industries. This precision is critical, as components across sectors like aerospace and automotive are increasingly designed with tighter tolerances, demanding the accuracy that CNC milling offers, often within ±0.01 mm.

Speed is another key advantage of CNC milling machines. The automation of milling processes significantly reduces production times, with some manufacturers reporting an efficiency increase of up to 75% through CNC integration. This is crucial in today’s fast-paced market, where time-to-market can make or break a product's success. Moreover, the repeatability of CNC machines ensures that the same high-quality results can be achieved consistently, which is invaluable for mass production scenarios.

Additionally, as highlighted by the National Institute of Standards and Technology (NIST), adopting CNC milling can lead to a 10-30% reduction in production costs through minimized material waste and improved workflow processes.

Exploring the Latest Trends in CNC Technology: Innovations Driving Industry Growth

The CNC machine market is experiencing remarkable growth, driven by technological innovations that enhance precision and efficiency in manufacturing processes. According to a report from Custom Market Insights, the CNC controller market size was valued at $3.2 billion in 2023 and is projected to reach $7.2 billion by 2033, reflecting an impressive compound annual growth rate (CAGR) of 8.3% from 2024 to 2033. This surge underscores the increasing reliance on CNC technology across various sectors, including aerospace, automotive, and electronics.

In addition, the overall CNC machine market is anticipated to grow significantly, from $101.22 billion in 2025 to $195.59 billion by 2032, at a CAGR of 9.9%. This growth can be attributed to advancements in automation and smart manufacturing practices, which not only improve production speed but also enhance precision and reduce operational costs. As industries continue to embrace these innovations, the demand for CNC milling machines and related technologies will likely remain strong, further transforming modern manufacturing landscapes.

Data-Driven Insights: How CNC Milling Machines Improve Quality Control and Output

The advancements in CNC milling machines are at the forefront of transforming quality control and output in modern manufacturing. By integrating machine learning (ML) within the Process Monitoring for Quality (PMQ) framework, industries can tackle persistent limitations in quality assurance, particularly in sectors such as automotive manufacturing. This data-driven approach allows manufacturers to monitor processes in real time, leading to enhanced precision and reduced waste. The CNC Controller Market is projected to escalate from USD 7.2 billion in 2025 to USD 12.4 billion by 2035, illustrating a robust growth driven by these technological innovations.

Tips: To maximize the benefits of CNC milling, consider investing in advanced machine learning tools that can analyze process data effectively. Additionally, ensure that your team is well-trained in integrating these new technologies into existing workflows to optimize productivity.

As AI continues to penetrate manufacturing ecosystems, predictive maintenance models leveraging sensor data can significantly enhance operational reliability. Future trends indicate a strong push towards digitalization, with data emerging as a critical asset on the shop floor. Companies are increasingly recognizing the need for real-time analytics to drive decision-making processes, ensuring they remain competitive in a rapidly evolving market.

Tips: Regularly evaluate your predictive maintenance strategies to align them with the latest deep learning models. This can lead to substantial improvements in machine efficiency and lower downtime across manufacturing systems.

Unlocking Precision: How CNC Milling Machines Revolutionize Modern Manufacturing

| Dimension | CNC Milling Machines | Impact on Quality Control | Output Efficiency (%) |

|---|---|---|---|

| Precision Tolerance (mm) | ±0.01 | Reduces waste by 15% | 90% |

| Production Speed (units/hr) | 30-50 | Consistency improved by 20% | 85% |

| Setup Time (minutes) | 10-20 | Improved by 30% | 95% |

| Machine Utilization (%) | 80% | Reduced errors by 25% | 92% |

Future Forecast: The Role of CNC Milling in the Advancements of Smart Manufacturing

The role of Computer Numerical Control (CNC) milling machines is becoming increasingly pivotal in the evolution of smart manufacturing. As industries adopt digital manufacturing technologies, productivity improvements are being felt across various sectors. The global CNC machine market is projected to expand at a compound annual growth rate (CAGR) of 5.5%, fueled by advancements in automation and precision engineering. By 2033, the CNC controller market alone is forecasted to grow from $3.2 billion in 2023 to a remarkable $7.2 billion.

Moreover, the milling machine market is poised for significant transformation, expected to reach USD 116,722.7 million by 2035. This growth highlights the integration of CNC technology and smart automation, which are redefining modern manufacturing paradigms. By 2050, we anticipate a manufacturing ecosystem that is not only intelligent and sustainable but also heavily interconnected, with cutting-edge metrology forming the backbone of this advanced manufacturing landscape. The ongoing advancements in CNC milling signify a revolution that is reshaping the future of production efficiency and precision.

Related Posts

-

7 Best Practices for Precision CNC Machining: Achieving 99.9% Accuracy in Manufacturing

-

Finding Top Quality Suppliers for Best Precision CNC Machining Solutions

-

Maximizing Value: How Exceptional After-Sales Service and Low Repair Costs in Best Rapid CNC Machining Set You Apart

-

Navigating the Future: How Best Rapid CNC Machining Will Shape Industry 2025 Trends

-

How to Choose the Right CNC Milling Machine for Your Business Needs

-

Top Strategies for Optimizing Metal Cutting CNC Processes for Enhanced Efficiency