Exploring CNC Metal Milling Machines at the 138th Canton Fair 2025: Industry Trends and Innovations

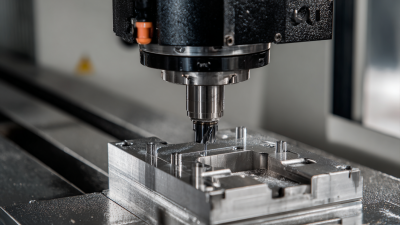

As the CNC metal milling machine industry continues to evolve, the 138th Canton Fair in 2025 will serve as a pivotal platform for showcasing the latest advancements and trends. With the global CNC milling market projected to reach $8.59 billion by 2026, growing at a CAGR of 6.2%, the significance of this technology in manufacturing cannot be overstated. Innovations such as automation and precision engineering are driving the demand for CNC metal milling machines, particularly in sectors like aerospace, automotive, and general manufacturing. The Fair provides an invaluable opportunity for industry professionals to engage with cutting-edge solutions, exchange ideas, and address the challenges of today’s dynamic market. By highlighting the latest technological innovations, this event aims to shape the future of CNC metal milling operations and facilitate meaningful connections among exhibitors and attendees.

As the CNC metal milling machine industry continues to evolve, the 138th Canton Fair in 2025 will serve as a pivotal platform for showcasing the latest advancements and trends. With the global CNC milling market projected to reach $8.59 billion by 2026, growing at a CAGR of 6.2%, the significance of this technology in manufacturing cannot be overstated. Innovations such as automation and precision engineering are driving the demand for CNC metal milling machines, particularly in sectors like aerospace, automotive, and general manufacturing. The Fair provides an invaluable opportunity for industry professionals to engage with cutting-edge solutions, exchange ideas, and address the challenges of today’s dynamic market. By highlighting the latest technological innovations, this event aims to shape the future of CNC metal milling operations and facilitate meaningful connections among exhibitors and attendees.

Emerging Trends in CNC Metal Milling Technology at the 138th Canton Fair

At the 138th Canton Fair 2025, CNC metal milling technology is set to showcase some of the most innovative trends shaping the industry. As manufacturers increasingly look for precision and efficiency, advancements in automation and software integration are at the forefront. Tools equipped with smart technology enable real-time monitoring and adjustments, significantly enhancing production capability. Additionally, the integration of artificial intelligence in CNC machines is revolutionizing the design process, making it more intuitive and user-friendly.

**Tips:** When exploring CNC machines at the fair, pay special attention to the latest features in automation that can streamline your workflow. Take note of how AI is being utilized to improve precision—ask vendors about their machine learning capabilities and how they can be tailored to your specific needs.

Emerging trends also point towards sustainability in CNC metal milling technology. Manufacturers are increasingly focused on reducing waste and utilizing energy-efficient practices. Enhanced coolant systems, for instance, are gaining traction, reducing reservoir sizes while improving tool life. This not only leads to lower costs but also aligns with the growing demand for environmentally-friendly manufacturing solutions.

**Tips:** Consider seeking out manufacturers that prioritize sustainability in their offerings. Gathering insights on eco-friendly innovations can offer a competitive edge in today’s market while contributing positively to the environment.

Exploring CNC Metal Milling Machines at the 138th Canton Fair 2025: Industry Trends and Innovations

| Feature | Details | Trend Level |

|---|---|---|

| Automation | Increased use of AI for process optimization | High |

| Material Advancements | Innovation in lightweight and durable alloys | Medium |

| Sustainability | Focus on eco-friendly manufacturing processes | High |

| Software Development | Integration of advanced CAD/CAM solutions | Medium |

| Safety Features | Enhanced safety protocols and automatic shut-off | High |

Innovative Machine Designs Showcased by Leading Manufacturers

At the 138th Canton Fair in 2025, the spotlight will be on the innovative machine designs that redefine CNC metal milling technology. Leading manufacturers are set to showcase an array of sophisticated machines that integrate advanced engineering and cutting-edge technology. These innovations feature enhanced precision and efficiency, catering to the evolving needs of industries like aerospace, automotive, and electronics.

One of the most exciting aspects is the integration of smart technology in machine designs. Manufacturers are introducing AI-powered CNC milling machines that can optimize tool paths in real-time, reducing waste and increasing productivity. Additionally, advancements in user interface design are making these machines more accessible, allowing operators to easily program complex tasks. As industry players gather at the fair to unveil these pioneering designs, it is clear that the future of CNC metal milling is set to be shaped by ingenuity and technological integration.

Sustainability Practices in CNC Milling: Industry Insights from the Fair

At the upcoming 138th Canton Fair in 2025, the focus on sustainability practices in CNC metal milling is becoming more pronounced. As industries increasingly prioritize eco-friendly solutions, the milling sector is no exception. Techniques that reduce waste, such as the use of reclaimed materials, are being explored and showcased by various exhibitors, reflecting a growing trend toward environmentally responsible manufacturing.

Innovations in CNC milling machines are also geared towards minimizing their carbon footprint. Enhanced energy efficiency and advanced software for optimal material usage are helping manufacturers adopt greener methods. Together, these initiatives are shaping a more sustainable future for the manufacturing industry, aligning with broader environmental goals observed at events like the International Contemporary Furniture Fair, where eco-conscious material choices are gaining traction. This evolution towards sustainable practices is not just a trend but a necessary shift in the CNC milling landscape.

Market Demand and Its Impact on CNC Milling Innovations

At the 138th Canton Fair in 2025, CNC metal milling machines are set to take center stage as industry players explore the latest trends and innovations. The growing market demand for precise machining capabilities is significantly influencing the evolution of CNC milling technology. As manufacturers seek to enhance productivity and efficiency, they are increasingly investing in advanced CNC systems that feature automation and smart technology. This shift not only addresses the immediate needs of the market but also paves the way for innovation in design and functionality.

Tips for businesses interested in leveraging CNC milling innovations include conducting thorough market research to identify trends and customer preferences. By understanding the specific requirements of various industries, manufacturers can tailor their products to meet emerging demands. Additionally, embracing sustainability and energy efficiency in machine design can attract environmentally conscious clients, further enhancing market appeal. As the industry evolves, staying informed about technological advancements will be crucial for maintaining a competitive edge.

Networking Opportunities for CNC Professionals at the Canton Fair

The 138th Canton Fair in 2025 is set to be a pivotal event for CNC professionals, offering extensive networking opportunities that are crucial for industry growth. As the CNC (Computer Numerical Control) machining sector continues to expand, with a projected market value exceeding $100 billion by 2026 according to a recent Market Research Future report, the fair serves as an ideal platform for professionals to connect.

Networking at such events can lead to collaborations that harness the latest technologies, ultimately driving innovation in metal milling machines.

Moreover, the Canton Fair will feature discussions on industry trends, highlighting advancements in automation and AI integration within CNC machining. A report from Mordor Intelligence indicates that the demand for CNC machines is expected to grow at a CAGR of over 7% through the next five years, underscoring the importance of staying connected with industry peers.

Attendees will have the chance to meet suppliers, manufacturers, and experts to share insights and explore potential partnerships in this rapidly evolving landscape, ultimately contributing to enhanced manufacturing efficiency and product quality in the CNC milling sector.

Related Posts

-

Finding Top Quality Suppliers for Best Precision CNC Machining Solutions

-

Maximizing Value: How Exceptional After-Sales Service and Low Repair Costs in Best Rapid CNC Machining Set You Apart

-

How to Choose the Best CNC Machine for Your Business Needs

-

Navigating the Future: How Best Rapid CNC Machining Will Shape Industry 2025 Trends

-

Unleashing the Power of Chinese Manufacturing with the Best CNC Aluminum Milling Machines

-

Exploring Unique Features and Applications of the Best Rapid CNC Machining Solutions