How to Choose the Right CNC Milling Machine for Your Business Needs

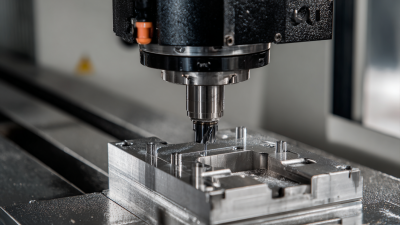

In the rapidly evolving landscape of manufacturing, choosing the right milling machine CNC is crucial for businesses aiming to enhance productivity and precision. According to a report by IBISWorld, the CNC machining industry has shown a steady growth rate of around 5.2% annually, driven by the increasing demand for advanced manufacturing technologies across various sectors such as aerospace, automotive, and medical devices. As companies look to optimize their operations, understanding the unique requirements of their projects is essential. Selecting the right CNC milling machine not only determines the quality of output but also impacts the overall operational efficiency and cost-effectiveness. With numerous options available in the marketplace, it becomes imperative for business owners to evaluate their specific needs and the capabilities of different milling machines CNC to make an informed decision.

Understanding Your Business Requirements for CNC Milling

When selecting the right CNC milling machine for your business, it is essential to thoroughly understand your specific requirements. The CNC controller market is projected to grow from $33.67 million in 2025 to $228.7 million by 2033, reflecting a stable compound annual growth rate (CAGR) of 2.2%. This growth highlights the increasing reliance on efficient and advanced machinery within the industry, making it crucial for businesses to select CNC machines that align with their operational goals and production demands.

Moreover, with the CNC machining center market expected to rise from $4.08 billion in 2025 to $4.50 billion by 2033 at a CAGR of 1.23%, companies must evaluate factors such as production volume, material types, and complexity of projects when choosing CNC milling machines. Identifying these needs will ensure that businesses invest in the appropriate technology that not only aids in efficiency but also enhances the overall productivity of their manufacturing processes.

How to Choose the Right CNC Milling Machine for Your Business Needs

This chart shows the distribution of various CNC milling machine specifications that businesses often consider when selecting a machine.

Key Features to Look for in a CNC Milling Machine

When choosing the right CNC milling machine for your business, it’s crucial to understand the key features that can significantly impact your operations. With the global CNC machine market expected to soar from $101.22 billion in 2025 to $195.59 billion by 2032, at a CAGR of 9.9%, investing in quality machinery is essential for sustaining competitiveness. Key features to look for include precision, versatility, and the technology incorporated into the machine, such as automated tool changing, which enhances efficiency and reduces downtime.

Tip 1: Ensure you select a CNC milling machine with high precision capabilities to handle your specific machining tasks effectively. Look for machines with advanced feedback systems and high-resolution encoders.

Tip 2: Consider the machine's versatility. A machine that can perform multiple functions—like milling and engraving—can help you save on costs and space in your workshop. The integration of modern technologies, such as the cyber-physical systems and augmented reality that aim to streamline the machining process further, can also enhance your production efficiency.

Making an informed decision requires balancing these features against your business needs, ensuring that your investment in CNC technology will yield fruitful returns.

Comparing Types of CNC Milling Machines for Different Applications

When selecting a CNC milling machine, it's crucial to examine the specific application and materials you will be working with. There are primarily three types of CNC milling machines: vertical, horizontal, and universal. Vertical milling machines are ideal for smaller parts and intricate designs, making them popular in industries where precision and detail are paramount. According to a report by Grand View Research, the vertical CNC milling machine market was valued at approximately $1.5 billion in 2022, with expectations to expand as manufacturers pursue high-accuracy machining solutions.

On the other hand, horizontal milling machines are better suited for high-volume production tasks, offering greater efficiency for larger workpieces due to their ability to handle heavy loads. The North American CNC milling machine market is projected to reach $2.1 billion by 2026, driven by an increasing demand for horizontal machining in automotive and aerospace sectors. Meanwhile, universal milling machines provide versatility by combining both vertical and horizontal capabilities, making them perfect for shops that require flexibility in operations. Understanding these distinctions can help businesses make informed decisions tailored to their production needs.

Budget Considerations: Cost vs. Quality in CNC Milling Machines

When selecting a CNC milling machine for your business, understanding the balance between cost and quality is essential. According to industry reports, businesses typically allocate between 15% to 25% of their total equipment budget for CNC machines, with a growing trend towards higher-end models that offer better precision and reliability. However, it’s crucial to consider not just the initial purchase price but also the long-term operational costs. High-quality machines often come with features that reduce wear and tear, ultimately leading to lower maintenance expenses and enhanced productivity.

Moreover, the right choice hinges on specific business needs. A study indicated that companies investing in mid-to-high-tier CNC machines reported up to 30% improved production efficiency compared to those who opted for lower-cost alternatives. This improvement was particularly noted in sectors such as woodworking and metal fabrication, where precision is paramount. Hence, while budget constraints are real, investing wisely in quality machinery can yield significant returns in performance and capability, making it a crucial consideration for any growing business in the CNC space.

How to Choose the Right CNC Milling Machine for Your Business Needs

| Machine Type | Price Range (USD) | Quality Rating (1-5) | Max Cutting Speed (ipm) | Versatility |

|---|---|---|---|---|

| Entry-Level CNC Mill | $4,000 - $10,000 | 3 | 100 | Basic |

| Mid-Range CNC Mill | $10,000 - $30,000 | 4 | 300 | Moderate |

| High-End CNC Mill | $30,000 - $100,000 | 5 | 500 | Advanced |

| Industrial CNC Mill | $100,000+ | 5 | 800 | Highly Versatile |

Evaluating Supplier Reputation and Support Services for CNC Machines

When choosing the right CNC milling machine for your business, evaluating supplier reputation and support services is crucial. A reliable supplier not only offers quality machinery but also provides ongoing support to ensure optimal functionality. According to recent industry reports, such as those by IMARC Group on various manufacturing sectors, understanding supplier reputation can enhance operational efficiency and minimize downtime. This is especially important in sectors like tractor and notebook manufacturing, where precision and reliability are paramount.

Tip: Before making a decision, research potential suppliers' customer reviews and client testimonials. A supplier with positive feedback and a solid track record can significantly impact the success of your operations.

Furthermore, inquire about the support services offered, including training, troubleshooting, and spare parts availability. Industry trends indicate that suppliers who provide comprehensive after-sales support can help businesses adapt to rapid technological advancements and maintain competitive advantages. Always ensure that the supplier’s commitment to customer service aligns with your production goals.

Tip: Establish direct communication with suppliers to gauge their responsiveness and willingness to assist. This early interaction can be an excellent predictor of the type of support you can expect throughout the lifecycle of your CNC machine.

Related Posts

-

Exploring Innovative Alternatives to Best Milling Machine CNC for Global Manufacturers

-

Discover China’s Leading CNC Metal Milling Machines: Global Sales Surge with Quality Assurance

-

Navigating the Future: How Best Rapid CNC Machining Will Shape Industry 2025 Trends

-

Unleashing the Power of Chinese Manufacturing with the Best CNC Aluminum Milling Machines

-

10 Reasons Why the Industrial CNC Milling Machine is the Best Investment for Your Business

-

Challenges Faced by Global Buyers When Sourcing Aluminum CNC Machines