How to Choose the Right Aluminum CNC Machine for Your Business Needs

Choosing the right aluminum CNC machine is critical for businesses aiming to enhance productivity and precision in their manufacturing processes. According to a report by MarketsandMarkets, the global CNC machine market is expected to reach $100.57 billion by 2026, with the metal segment, including aluminum, driving significant demand due to its lightweight and durable properties.

Aluminum CNC machines offer exceptional versatility and efficiency, making them essential in industries such as aerospace, automotive, and electronics. However, selecting the most suitable model involves evaluating factors like machine size, tooling options, and software capabilities, as well as considering specific production requirements.

As businesses increasingly adopt automation and advanced manufacturing technologies, making an informed decision on the right aluminum CNC machine can provide a competitive edge and improve operational performance.

Understanding Your Business Requirements for CNC Machining

When selecting an aluminum CNC machine for your business, it's crucial to start by thoroughly understanding your specific business requirements. According to a report from MarketsandMarkets, the CNC machining market is projected to grow to $100 billion by 2025, driven by increasing demand for precision components across various industries. This growth underscores the necessity for businesses to align their machining capabilities with their production goals, whether that means maximizing efficiency, enhancing production volume, or minimizing operational costs.

The choice of CNC machine should also reflect the scale and types of projects your business undertakes. If your operations are centered on high-precision, low-volume production, a CNC machine with advanced capabilities might be preferred. Conversely, businesses focused on large-scale production may benefit from machines designed for speed and efficiency, supporting faster turnaround times. A survey by the National Tooling and Machining Association indicated that 70% of manufacturers consider versatility in their machinery as a key factor, highlighting the importance of a machine that can adapt to different tasks and materials as business demands evolve. Understanding these parameters will enable you to make a more informed decision when investing in CNC technology.

Aluminum CNC Machines: Monthly Sales Distribution (2023)

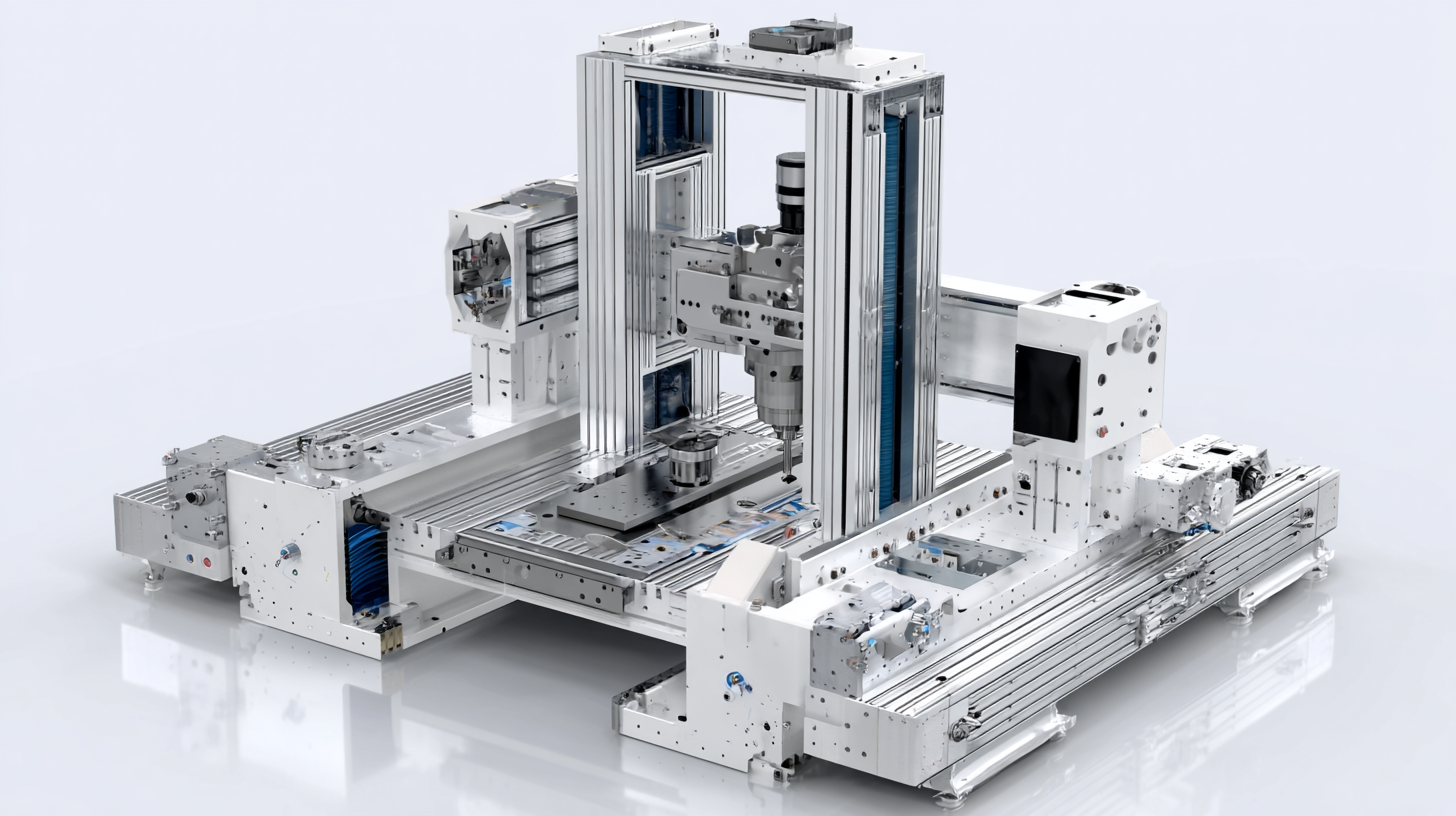

Exploring Different Types of Aluminum CNC Machines

When selecting the right aluminum CNC machine for your business needs, understanding the various types available is crucial. The market offers a range of machines, including vertical machining centers, horizontal machining centers, and router CNC machines, each designed to handle aluminum differently. According to recent industry reports from MarketsandMarkets, the demand for CNC machines is projected to grow significantly, reaching around $100 billion by 2025. This growth is driven by the increasing need for precision engineering in industries such as aerospace, automotive, and electronics, where aluminum’s lightweight and corrosion resistance are highly valued.

Vertical machining centers (VMCs) are ideal for tasks that require precision and flexibility. They typically operate with higher spindle speeds, which is advantageous for machining softer aluminum alloys. Alternatively, for high-volume production, horizontal machining centers (HMCs) provide better automation and tooling efficiency, making them suitable for batch production of aluminum parts. A report by Grand View Research highlights that around 40% of CNC machines are utilized for non-ferrous metals like aluminum, indicating an increasing trend towards specialized CNC machining solutions in various sectors. Understanding these differences can significantly impact production efficiency and quality in your manufacturing processes.

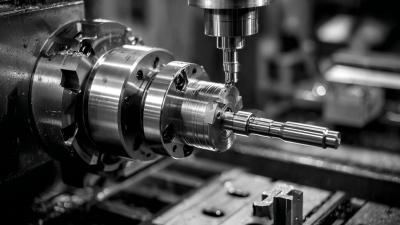

Key Features to Look for in an Aluminum CNC Machine

When selecting the right aluminum CNC machine for your business needs, it's essential to focus on several key features that ensure efficiency and precision in your manufacturing process. As reported, the global CNC machine market is projected to grow significantly, reaching $195.59 billion by 2032, indicating the importance of investing in high-quality machinery.

First, consider the machine's precision and accuracy. High-precision CNC machines contribute to improved product quality and reduced waste, which is crucial in competitive markets. Additionally, multi-axis machining capabilities enhance the machine’s versatility, enabling it to handle complex geometries and various designs.

Tips:

- Always check the tolerance levels specified by the manufacturer; they should align with your production requirements.

- Evaluate the feedback systems and real-time monitoring capabilities, as these can significantly enhance operational efficiency and reduce downtimes.

Lastly, assess the machine's automation features. Advanced CNC machines now incorporate artificial intelligence, which can lead to smarter decision-making during production, driving productivity even further. Investing in a machine with intelligent features can help future-proof your operations in a rapidly evolving market landscape.

Evaluating Cost vs. Quality: Making the Right Investment

When selecting an aluminum CNC machine for your business, it is crucial to evaluate the cost versus quality to make an informed investment. According to a recent report by the International Federation of Robotics, the global market for CNC machines is projected to reach $100 billion by 2025, indicating a growing demand for high-quality machinery. However, businesses must tread carefully; opting for the cheapest model can lead to long-term costs that outweigh initial savings. Studies show that lower-quality machines often result in increased maintenance expenses and production downtime, with a 30% increase in operational costs over five years.

Furthermore, a comprehensive analysis from Technavio highlights that businesses investing in higher-quality CNC machines experience a 20-25% increase in productivity. This is because high-end machines often come equipped with advanced technologies that enhance precision and efficiency, ultimately leading to higher-quality output. Therefore, while the upfront costs of a premium aluminum CNC machine may be substantial, the potential return on investment through improved performance and lower lifecycle costs substantiate the expense. Balancing cost with quality is not just a financial decision; it’s a strategic move that can significantly impact your business's competitiveness in the market.

Considerations for Maintenance and Support Services

When selecting an aluminum CNC machine, understanding the maintenance and support services offered by manufacturers is critical to ensure long-term productivity and efficiency. The average lifespan of a CNC machine can extend over a decade, making ongoing support essential. A recent report indicates that companies who invest in comprehensive maintenance services can reduce machine downtime by up to 30%, which significantly impacts operational costs. Therefore, evaluating the maintenance services that come with a CNC machine ought to be a priority.

Moreover, as businesses transition to more automated and technologically advanced solutions, the importance of customer-centric support services cannot be overstated. A study revealed that organizations with strong digital support frameworks experience a 20% increase in customer satisfaction. It is crucial to inquire about the availability of 24/7 support and the responsiveness of service teams before finalizing any purchase. Implementing proactive maintenance schedules not only extends the life of CNC machines but also prevents small issues from escalating into costly repairs, ultimately safeguarding your investment.

Related Posts

-

The Future of Advanced Aluminum Milling Machines in Modern Manufacturing

-

Challenges Faced by Global Buyers When Sourcing Aluminum CNC Machines

-

How to Master the Art of Aluminum Machining for Precision Engineering

-

5 Compelling Reasons Why Best Rapid CNC Machining Is Essential for Your Business Success

-

5 Reasons Why Rapid CNC Machining is Your Best Option for Global Sourcing

-

How to Choose the Best Brass CNC Components for Your Manufacturing Needs: A Comprehensive Guide