Why Choose an Aluminum CNC Machine for Your Next Project

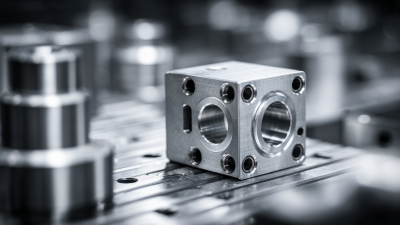

In the rapidly evolving landscape of manufacturing, the choice of machinery plays a pivotal role in determining the efficiency and quality of production processes. Among the diverse options available, aluminum CNC machines have emerged as essential tools for both small-scale workshops and large industrial operations. According to a report by Grand View Research, the global CNC machining market is expected to reach $100 billion by 2025, with aluminum accounting for a significant portion of the materials being processed due to its lightweight, durability, and corrosion resistance.

Aluminum CNC machines not only enhance precision and reduce waste but also facilitate the production of intricate designs at a faster pace compared to traditional machining methods. Industry analysis indicates that businesses utilizing CNC machining for aluminum components see a reduction in operational costs by as much as 30%, underscoring the technology's ability to optimize resource use while maintaining high standards of quality. As manufacturers seek to improve their competitiveness and maintain sustainability, investing in state-of-the-art aluminum CNC machines is becoming increasingly vital for achieving innovative and cost-effective solutions in various applications.

Advantages of Aluminum CNC Machines in Modern Manufacturing Processes

Aluminum CNC machines have become increasingly integral in modern manufacturing due to their unique advantages. According to industry reports, the global CNC machine market is projected to reach $100 billion by 2026, with aluminum components driving much of this growth. The lightweight nature of aluminum allows for faster machining speeds, reducing production time and costs significantly. Additionally, aluminum’s excellent thermal conductivity and corrosion resistance contribute to longer tool life, enhancing overall efficiency in various applications, from aerospace to automotive industries.

One essential tip for maximizing the benefits of aluminum CNC machining is to choose the correct tooling. High-speed steel (HSS) or carbide tools can offer precise cuts and longevity, but it’s vital to consider factors like cutting speed and feed rate to optimize performance. Another important aspect is maintaining proper coolant systems to prevent overheating, which can lead to material deformation and poor finish quality.

Moreover, aluminum’s recyclability makes it a sustainable choice for manufacturers seeking to minimize their environmental impact. Reports show that aluminum can be recycled with only 5% of the energy required to produce new aluminum, making it an eco-friendly option in a production landscape increasingly focused on sustainability. This factor not only helps in reducing waste but also aligns with corporate responsibility goals many organizations are adopting today.

Industry Statistics on Efficiency and Precision of Aluminum CNC Machining

Aluminum CNC machining has emerged as a leading choice in various industries due to its exceptional efficiency and precision. Recent industry statistics reveal that CNC machines can achieve tolerances as tight as

±0.005 inches, significantly improving the quality of machined aluminum components. This level of precision is crucial in sectors such as aerospace and automotive, where even the slightest deviation can lead to performance issues or safety hazards. The ability to replicate these precise specifications consistently also reduces waste, making the machining process not only cost-effective but environmentally friendly as well.

Moreover, the efficiency of aluminum CNC machining is highlighted by the ability to streamline production processes. Industry reports indicate that companies utilizing CNC technology for aluminum fabrication can increase their productivity by up to

30% compared to traditional machining methods. This is largely due to the automated nature of CNC machines, which minimize human error and allow for longer operational hours without sacrificing quality. Consequently, manufacturers are able to meet tighter deadlines and respond swiftly to market demands, giving them a competitive edge in an increasingly fast-paced environment.

Comparative Analysis: Aluminum vs. Other Materials in CNC Applications

When it comes to CNC machining, selecting the right material is crucial for achieving optimal performance and efficiency. Aluminum stands out as one of the preferred choices for various applications due to its excellent mechanical properties. Its strength-to-weight ratio is unmatched, making it an ideal candidate for industries ranging from aerospace to automotive. According to a report by Grand View Research, the global aluminum market size was valued at $154.77 billion in 2019 and is projected to grow at a CAGR of 3.6% from 2020 to 2027. This growth reflects an increasing demand for aluminum components in precision manufacturing.

Comparatively, materials such as steel and plastic also find use in CNC applications; however, they come with inherent limitations. While steel is stronger and more durable, its higher weight can complicate machining processes and increase costs, especially in terms of energy consumption. Plastics may offer lower manufacturing costs, but they don't match aluminum's thermal and electrical conductivity. According to data from the International Aluminum Institute, aluminum's thermal conductivity is about 205 W/m·K, which significantly enhances its performance in applications requiring efficient heat dissipation. This property, combined with its versatility in machining, solidifies aluminum's position as a leading material in CNC operations.

Cost-Effectiveness of Aluminum CNC Machining for Small to Large Projects

Aluminum CNC machining has become an increasingly popular choice for projects of all sizes due to its remarkable cost-effectiveness. According to a report by the Freedonia Group, the market for CNC machined products is projected to reach $100 billion by 2025, driven significantly by the versatility and affordability of aluminum components. This material not only offers a favorable strength-to-weight ratio but also does so at a lower price point compared to alternatives such as titanium or high-performance polymers. For small to medium-sized enterprises, this translates into considerable savings on materials without compromising quality or performance.

Moreover, aluminum's machinability allows for rapid production times, which is essential for businesses looking to accelerate product development cycles. A study from the Machining Journal highlights that CNC machines can achieve precision tolerances within 0.01 mm, enhancing the manufacturing process's efficiency and reducing waste. This speed and precision make aluminum CNC machining an attractive option even for large projects where time and cost are critical. Thus, utilizing aluminum not only minimizes initial investment but also optimizes operational costs over the project lifecycle, making it a wise choice for an array of applications from aerospace to consumer electronics.

Applications and Industries Benefiting from Aluminum CNC Machining Technology

Aluminum CNC machining technology has become increasingly vital across various applications and industries due to its versatility and efficiency. One of the primary sectors benefiting from this technology is aerospace. In aerospace manufacturing, precision and weight reduction are critical. Aluminum components, which are lightweight yet incredibly strong, can be intricately machined using CNC processes to produce parts such as airframes, engine mounts, and brackets. This ensures not only durability but also enhances fuel efficiency in aircraft.

Another sector that extensively utilizes aluminum CNC machining is the automotive industry. As manufacturers strive to produce lighter and more fuel-efficient vehicles, aluminum has emerged as a preferred material for engine components, transmission housings, and structural parts. CNC machining allows for the meticulous creation of complex shapes and tight tolerances, which are essential for high-performance automotive applications. Furthermore, CNC machines facilitate faster production rates and reduced wastage, contributing to better overall efficiency in automotive manufacturing.

In addition to aerospace and automotive, the electronics industry also reaps significant benefits from aluminum CNC machining. The demand for lightweight and heat-dissipating components in consumer electronics has led to an increased need for machined aluminum parts, such as enclosures for laptops and smartphones. CNC machining plays a crucial role in delivering precision-engineered parts that not only meet functional requirements but also enhance the aesthetic appeal of consumer products. This technology fosters innovation while ensuring that industries can cope with the evolving demands of modern design and production.

Related Posts

-

Challenges Faced by Global Buyers When Sourcing Aluminum CNC Machines

-

How to Choose the Right Aluminum CNC Machine for Your Business Needs

-

2025 How to Choose the Fast CNC Machine for Your Manufacturing Needs

-

How to Achieve Fast Precision with Best Quick Turn Machining Techniques

-

Comparing the Top Innovations in Prototype Machining Techniques

-

Trustworthy Quality in Best Low Volume CNC Machining from China for Global Markets