7 Best Practices for Precision CNC Machining: Achieving 99.9% Accuracy in Manufacturing

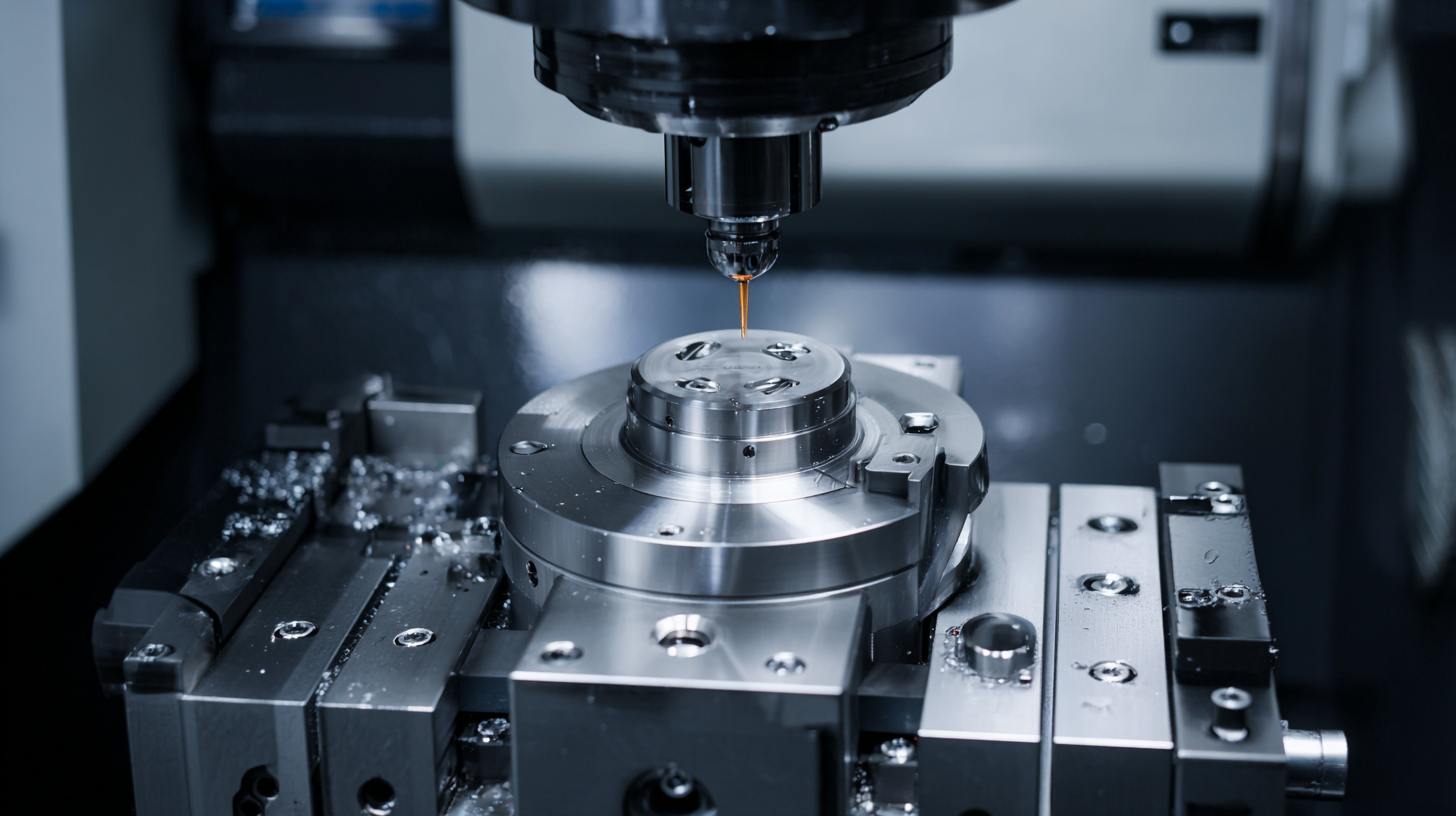

In today's fast-paced manufacturing landscape, the demand for precision CNC machining has surged, driven by industries requiring unparalleled accuracy and efficiency. According to a report by the International Journal of Advanced Manufacturing Technology, achieving an accuracy level of 99.9% is not just a benchmark but a necessity for competitive advantage and product quality. Precision CNC machining enables manufacturers to produce complex parts with minimal tolerances, which is vital in sectors such as aerospace, automotive, and medical devices. Moreover, the global CNC machining market is projected to reach $100 billion by 2025, emphasizing the critical role of precision in driving technological advancements. In this blog, we will explore the seven best practices that can help achieve such remarkable accuracy, ensuring optimal outcomes for manufacturers and their clients alike.

Understanding the Fundamentals of CNC Machining Accuracy: Key Metrics and Standards

In the world of CNC machining, achieving high accuracy is paramount, and touch probing systems have emerged as a key technology for realizing this precision. These systems enable automatic data collection, significantly enhancing the efficiency and reliability of measurements during the machining process. According to a recent industry report, the integration of touch probing technology can improve dimensional accuracy by up to 99.9%, which is vital for industries that require stringent tolerances, such as aerospace and automotive manufacturing.

The application of touch probing systems allows for real-time adjustments and validation of the machining process, reducing the occurrence of errors and enhancing overall production quality. For instance, with systems like those on HiTorque Mini Mills, users can utilize advanced probing tools to gather precise data continuously. This enables manufacturers to maintain compliance with rigorous industry standards and metrics, which are critical for ensuring product quality and customer satisfaction. The data collected not only helps in adjusting machining parameters on-the-fly but also aids in troubleshooting and predictive maintenance, ensuring that machines operate optimally over their lifespan.

Essential Calibration Techniques for CNC Machines: Achieving Consistent Precision

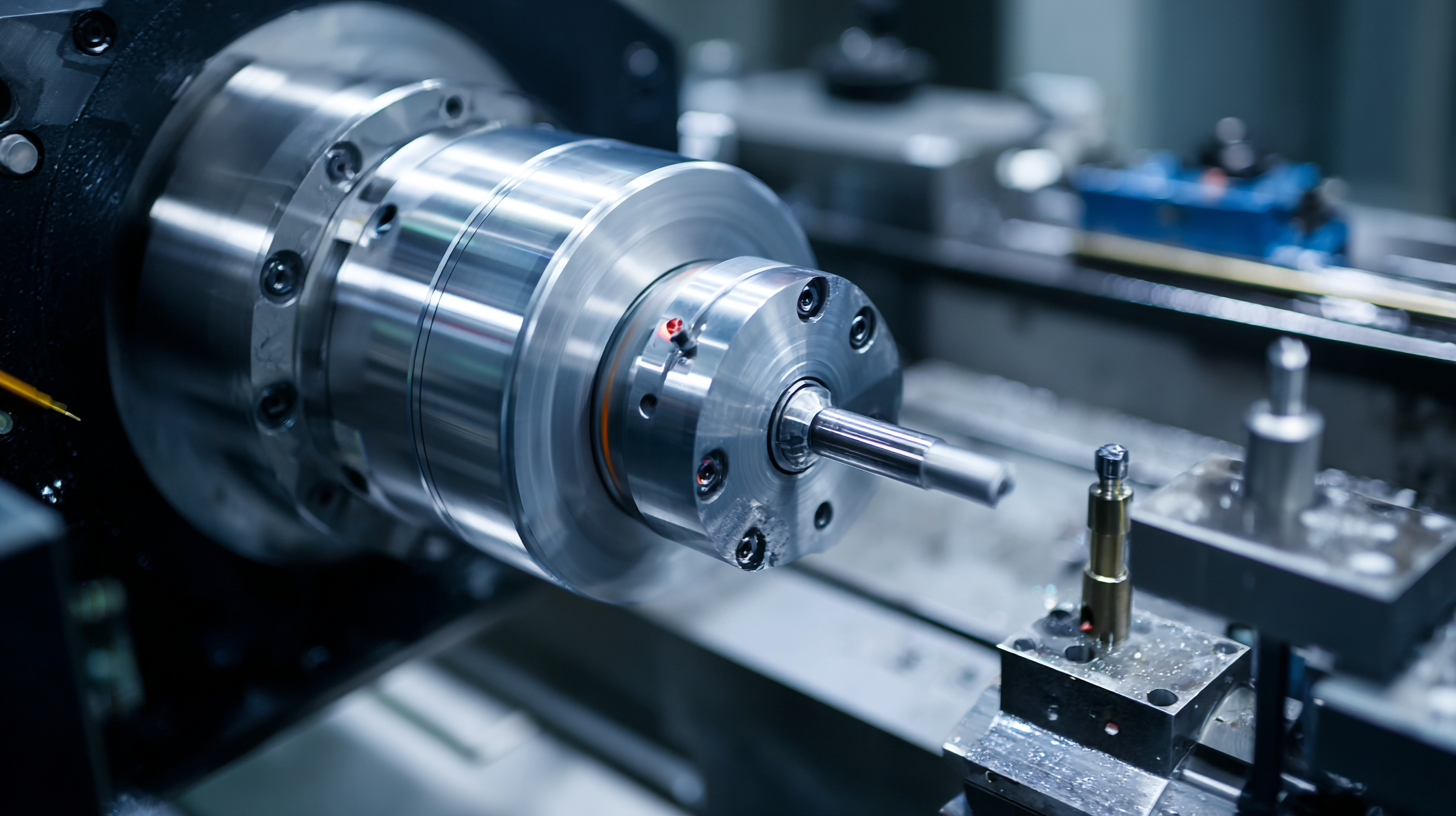

Achieving consistent precision in CNC machining requires meticulous calibration techniques that ensure your machines operate at peak performance. One vital tip is to regularly check the machine's temperature. Precise CNC machining can be significantly affected by temperature fluctuations, leading to material expansion or contraction. Maintaining a stable environment and using temperature-controlled enclosures can help mitigate these issues, ensuring your components meet their required tolerances.

Another important practice is to routinely calibrate the cutting tools and machine axes. Implementing regular tool wear monitoring can prevent inaccuracies during the production process. Utilize precision measurement tools to assess the tool's condition and replace or sharpen them as necessary. Additionally, ensuring that the machine axes are aligned correctly will minimize errors in the cutting process.

Finally, invest in quality calibration equipment. Using high-precision gauges and laser systems can help achieve finer adjustments that lead to enhanced accuracy. By integrating these calibration techniques into your CNC operations, you will be better positioned to reach that coveted 99.9% accuracy in your manufacturing processes.

7 Best Practices for Precision CNC Machining

Material Selection and Its Impact on Precision CNC Machining: An Analytical Approach

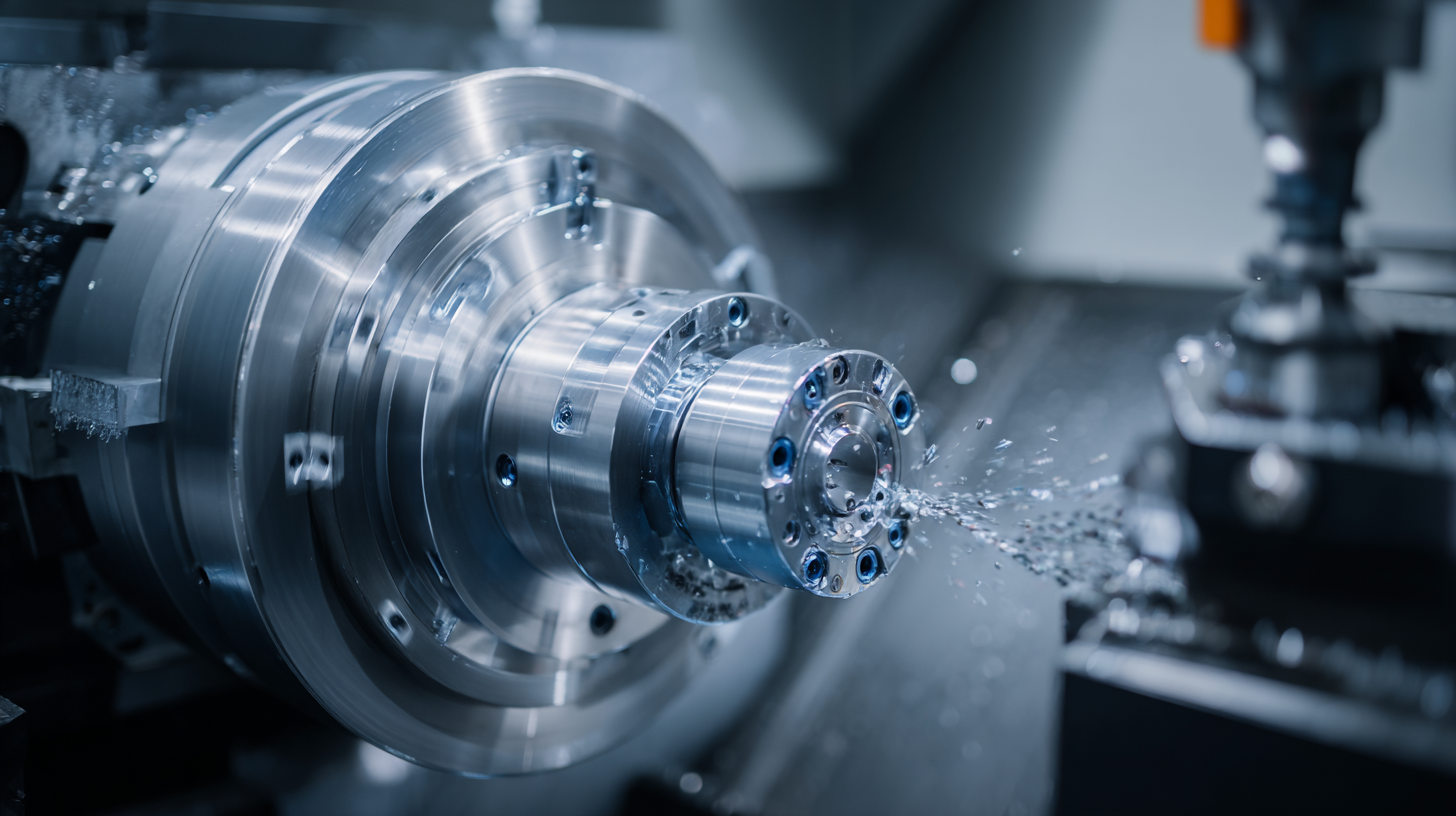

Material selection plays a crucial role in achieving high precision in CNC machining, impacting both the accuracy and the overall efficiency of the manufacturing process. Recent studies highlight the importance of using advanced materials, like LM25 aluminum alloy reinforced with vanadium carbide composites, which exhibit superior machinability and robust performance under varying conditions. This is where analytical modeling combined with modern techniques like deep neural networks come into play, allowing engineers to predict material behavior during machining and thus optimize the entire process for greater precision.

Additionally, understanding the dynamic characteristics of machine tools is essential to mitigate issues such as cutting chatter, which can significantly affect surface quality and dimensional accuracy. Implementing control methods that couple thermal and mechanical properties can help suppress these vibrations, leading to improved performance. Furthermore, using sophisticated modeling techniques enables the assessment of factors such as static deflection, which is crucial for maintaining tolerances, especially in thin-walled workpieces. Ultimately, integrating smart material selection with advanced analytical methods can pave the way to achieving that elusive 99.9% accuracy in CNC machining, driving innovation and efficiency in the manufacturing landscape.

Implementing Advanced Tooling and Software Solutions for Enhanced Accuracy

In the realm of precision CNC machining, implementing advanced tooling and software solutions is essential for achieving remarkable accuracy. Modern technologies, including AI-enhanced systems, are transforming traditional manufacturing processes, enabling companies to streamline operations and minimize human error. By utilizing sophisticated software models, manufacturers can optimize machining parameters, leading to enhancements in both efficiency and product quality. For instance, machine learning algorithms can predict tool wear and maintenance needs, ensuring machinery operates at peak performance with a 99.9% accuracy rate.

Additionally, the integration of Industry 4.0 principles, such as IoT devices and automation, allows for real-time monitoring of production lines. This digitization not only boosts precision but also provides valuable data insights that can further refine manufacturing processes. The reliance on data-driven decision-making reveals new avenues for continuous improvement, driving manufacturers toward achieving unparalleled accuracy and cost-effectiveness. Ultimately, the marriage of advanced tooling and innovative software solutions is paving the way for a new era of precision machining, where operations are more agile and responsive than ever before.

7 Best Practices for Precision CNC Machining: Achieving 99.9% Accuracy in Manufacturing

| Best Practice | Description | Impact on Accuracy (%) | Implementation Cost ($) |

|---|---|---|---|

| Regular Calibration | Ensure CNC machines are calibrated frequently to maintain precision. | 30% | 500 |

| Advanced Tooling | Utilize high-quality, specialized tools for various machining processes. | 25% | 2000 |

| Software Integration | Implement software solutions for real-time monitoring and adjustments. | 20% | 3000 |

| Material Selection | Choose appropriate materials that enhance machining accuracy. | 15% | 1500 |

| Employee Training | Regular training for operators to ensure they are skilled and updated. | 10% | 800 |

| Process Optimization | Analyze and improve machining processes to reduce errors. | 10% | 1000 |

| Regular Maintenance | Scheduled maintenance ensures machines operate at peak performance. | 5% | 600 |

Quality Control Measures: Data-Driven Practices to Ensure Manufacturing Precision

In the realm of precision CNC machining, maintaining accuracy is paramount, and implementing robust quality control measures can significantly enhance production outcomes. Research from the National Institute of Standards and Technology reveals that organizations can improve their manufacturing precision by up to 30% through data-driven practices. These practices include real-time monitoring of machining processes, employing statistical process control (SPC), and analyzing variances with advanced analytics tools. By systematically collecting and assessing data, manufacturers can detect anomalies early, thereby reducing the risk of defects and rework.

Moreover, integrating predictive analytics into CNC machining allows manufacturers to foresee potential failure points in real-time. A report from Deloitte indicates that companies using predictive maintenance techniques can reduce unplanned downtime by up to 50%. This proactive approach not only ensures that machines operate at peak efficiency but also helps maintain the desired accuracy levels, achieving near-perfect precision in manufacturing processes. By leveraging technology and data analytics, manufacturers can strive towards the coveted 99.9% accuracy, driving quality and efficiency in their production systems.

Related Posts

-

Finding Top Quality Suppliers for Best Precision CNC Machining Solutions

-

Maximizing Value: How Exceptional After-Sales Service and Low Repair Costs in Best Rapid CNC Machining Set You Apart

-

Navigating the Future: How Best Rapid CNC Machining Will Shape Industry 2025 Trends

-

How to Choose the Best CNC Machine for Your Business Needs

-

Exploring Unique Features and Applications of the Best Rapid CNC Machining Solutions

-

10 Reasons Why the Industrial CNC Milling Machine is the Best Investment for Your Business