10 Best One Off CNC Machining Techniques for Precision Manufacturing in 2023

In the rapidly evolving landscape of precision manufacturing, "one off CNC machining" has emerged as a critical technique for producing high-quality, customized components. According to a recent report by MarketsandMarkets, the CNC machining market is projected to reach USD 100.2 billion by 2025, growing at a CAGR of 6.3% due to rising demand for precision components across various industries, including aerospace, automotive, and medical. This growth is largely attributed to the ability of one off CNC machining to deliver tailored solutions that meet specific design requirements and enhance production efficiency.

As manufacturers continue to seek innovative methods to maintain competitiveness, understanding the best one off CNC machining techniques available can significantly impact operational success. In this guide, we will explore the ten best techniques that are shaping the future of precision manufacturing in 2023.

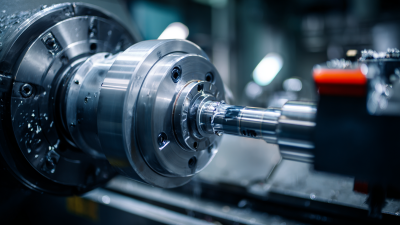

Understanding CNC Machining: Key Concepts for Beginners and Experts

CNC machining, or Computer Numerical Control machining, is a pivotal technology in precision manufacturing, where computer software dictates the movements of production equipment. For beginners, understanding the foundational concepts of CNC machining is essential. It begins with the recognition that CNC machines can execute complex designs with remarkable accuracy, making them indispensable in industries ranging from aerospace to automotive. These machines function by interpreting digital designs into physical parts, employing a variety of tools to cut, drill, and shape materials according to exact specifications.

CNC machining, or Computer Numerical Control machining, is a pivotal technology in precision manufacturing, where computer software dictates the movements of production equipment. For beginners, understanding the foundational concepts of CNC machining is essential. It begins with the recognition that CNC machines can execute complex designs with remarkable accuracy, making them indispensable in industries ranging from aerospace to automotive. These machines function by interpreting digital designs into physical parts, employing a variety of tools to cut, drill, and shape materials according to exact specifications.

For experienced manufacturers, mastering CNC machining techniques can lead to improved efficiency and cost-effectiveness. Techniques such as milling, turning, and electrical discharge machining provide versatility in the types of materials and geometries that can be produced. As technology advances, incorporating automation and smart software into CNC operations enhances productivity and allows for real-time adjustments during the manufacturing process. Understanding these key concepts ensures that both novices and experts can leverage CNC machining to push the boundaries of what is possible in precision manufacturing today.

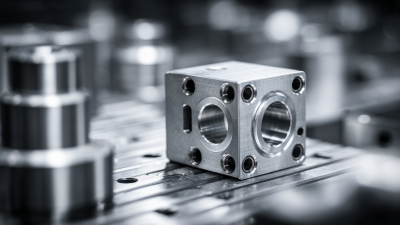

Top Materials for One-Off CNC Machining: Choosing the Right Options

When it comes to one-off CNC machining, selecting the right materials is crucial for ensuring precision and durability. Various materials can be employed, each offering distinct benefits depending on the project's specific requirements. For instance, aluminum is a popular choice for its excellent machinability and lightweight properties, making it ideal for applications where performance and efficiency matter. Additionally, polymers like nylon and acetal provide versatility and resistance to wear, frequently used in prototypes or low-volume production runs.

Another noteworthy material for one-off CNC machining is stainless steel. Its strength and corrosion resistance make it suitable for demanding environments, such as automotive and aerospace applications. Furthermore, advanced materials like composites can enhance strength while reducing weight, catering to industries that prioritize innovation and performance. Ultimately, choosing the right material not only influences the manufacturing process but also impacts the product's functionality and lifespan, making it essential to consider both mechanical properties and intended use when deciding on materials for your CNC projects.

Precision Techniques: How to Optimize Tool Paths for Enhanced Accuracy

In the realm of CNC machining, optimizing tool paths is crucial for achieving enhanced accuracy in precision manufacturing. One key technique to consider is implementing advanced algorithms that analyze the workpiece geometry. By doing so, manufacturers can create more efficient tool paths that minimize unnecessary movements, reducing cycle times and improving the overall quality of the finished product. This attention to detail ensures that the CNC machine maintains its trajectory with high fidelity, leading to precise dimensioning and surface finishes.

Additionally, incorporating adaptive feed rates offers another layer of optimization. By adjusting the speed at which the CNC machine operates based on feedback from the machining process, manufacturers can maintain optimal cutting conditions. This not only maximizes tool life but also helps to prevent tool wear and tear, which can compromise precision. As technology continues to evolve, embracing these precision techniques will be essential for manufacturers looking to stay competitive in the ever-evolving landscape of CNC machining.

Post-Processing Methods: Finishing Techniques to Elevate Your CNC Parts

Post-processing methods play a crucial role in enhancing the quality and precision of CNC machined parts. As the demand for high-performance components continues to rise, manufacturers are increasingly turning to advanced finishing techniques to achieve superior surface quality and dimensional accuracy. Techniques such as electroplating, anodizing, and shot peening not only improve aesthetic appeal but also enhance mechanical properties. According to a report by MarketsandMarkets, the global CNC machining market is expected to grow to USD 100 billion by 2025, highlighting the growing importance of effective post-processing strategies.

In 2023, modern additive manufacturing technologies have begun to influence traditional CNC machining processes, particularly in the realm of post-processing. Techniques like laser sintering and selective laser melting allow for intricate designs that can be further refined through CNC machining. A study from the Journal of Materials Processing Technology indicates that integrating additive manufacturing with CNC processes can reduce production times by up to 40%, while simultaneously increasing design flexibility and material utilization. As manufacturers adopt these innovative approaches, the quality of CNC parts will continue to reach new heights, driven by sophisticated post-processing methods.

10 Best One Off CNC Machining Techniques for Precision Manufacturing in 2023

Cost-Effective Strategies: Minimizing Waste and Maximizing Efficiency in CNC Projects

In today's competitive landscape of CNC machining, cost-effective strategies are essential for minimizing waste and maximizing efficiency in projects. According to a recent report by the Additive Manufacturing Institute, companies that implement advanced CNC techniques can reduce material waste by up to 30%. This highlights the importance of selecting the right machining processes and materials to optimize resource utilization. Utilizing adaptive control systems can further enhance operational efficiency, allowing manufacturers to tweak parameters in real-time and reduce cycle times by as much as 15%.

One effective tip for CNC efficiency is to conduct thorough pre-production simulations. By leveraging software such as CAD/CAM systems, manufacturers can identify potential bottlenecks and adjust designs accordingly, helping to avoid unnecessary waste. Additionally, employing advanced tooling strategies, like using multi-functional tools, can significantly improve material usage and reduce setup times, ultimately yielding a more streamlined production process.

Investing in employee training is equally crucial. A skilled workforce can identify inefficiencies and propose improvements, leading to better decision-making on the shop floor. According to industry studies, organizations that prioritize employee training report a 20% increase in productivity. By fostering a culture of continuous improvement, manufacturers can ensure that their CNC machining processes are both cost-effective and high-quality, securing a competitive edge in the market.

Related Posts

-

Trustworthy Quality in Best Low Volume CNC Machining from China for Global Markets

-

5 Compelling Reasons Why Best Rapid CNC Machining Is Essential for Your Business Success

-

Maximizing Value: How Exceptional After-Sales Service and Low Repair Costs in Best Rapid CNC Machining Set You Apart

-

Navigating the Future: How Best Rapid CNC Machining Will Shape Industry 2025 Trends

-

5 Secrets to Finding the Best Quick Turn CNC Machining Services

-

How to Achieve Fast Precision with Best Quick Turn Machining Techniques