2026 Best Ball Screw for Sale Options What to Look For?

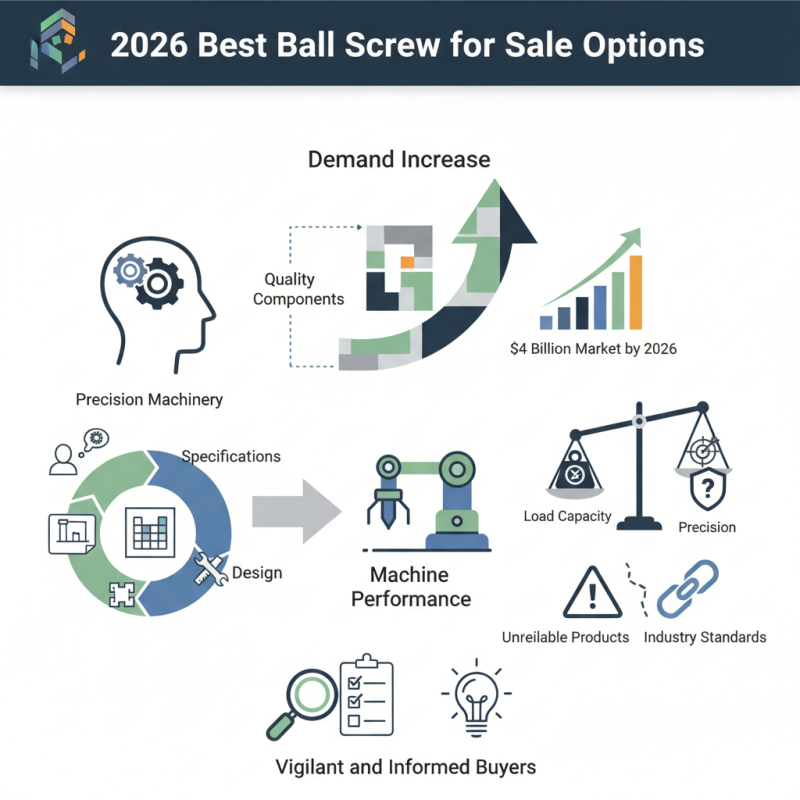

As the demand for precision machinery increases, the search for quality components becomes critical. The "ball screw for sale" market has witnessed significant growth. According to a report by Global Market Insights, the market is projected to exceed $4 billion by 2026. This surge highlights the importance of selecting the right ball screw for various applications.

Industry expert James Thompson, a leading engineer in motion control systems, states, "Choosing the right ball screw impacts overall machine performance." His insight underlines the necessity of understanding specifications, materials, and design when considering ball screws for sale. Users must be aware that different applications require different features.

When evaluating options, it is essential to consider factors like load capacity and precision. However, one must also be cautious. Not all suppliers provide reliable products. Some ball screws may not meet industry standards, leading to unforeseen issues. As the market evolves, potential buyers should remain vigilant and informed.

Best Ball Screw Types for Various Applications in 2026

When selecting the best ball screws in 2026, understanding various types is crucial. Different applications require specific characteristics. For instance, high-load applications often benefit from precision ball screws. They provide excellent accuracy and stability, making them ideal for manufacturing machinery. On the other hand, miniaturized ball screws are suitable for compact spaces, like in robotics. Their size doesn't compromise performance but enhances efficiency.

It's essential to consider the material of the ball screw. Steel options are robust and well-suited for heavy loads. However, stainless steel variants offer better resistance to corrosion. For certain applications, this is vital. Sometimes, the selection process can be overwhelming. You may find it tough to balance cost and quality. Reflecting on your specific needs can help simplify this. Analysing performance requirements will guide you toward the right type. Don't overlook the importance of proper installation and maintenance. These factors greatly influence longevity and efficiency.

Key Features to Consider When Choosing a Ball Screw

When looking for the best ball screw, considering key features is essential. Ball screws play a crucial role in motion control. They convert rotary motion into linear motion efficiently. Precision is vital. Look for the accuracy rating. A small error can lead to machine malfunctions.

Material quality matters too. High-quality steel alloys are preferred. This enhances durability and wear resistance. Be wary of low-cost options that may compromise performance. They might save money but lead to failures over time.

Tips: Always check for lubrication. A well-lubricated ball screw performs better and lasts longer. Inspect the lead screw and nut as well. Proper alignment is necessary. A misaligned ball screw can cause excessive wear. Regular maintenance checks should not be overlooked.

Consider load capacity. Every application has specific requirements. Calculating the load is crucial for selecting the right one. Too much load can damage the screw. Understand your machine's needs before making a decision. It pays off to research thoroughly.

Performance Metrics: Load Capacity and Speed Ratings

When choosing the best ball screw, performance metrics like load capacity and speed ratings are critical. Load capacity refers to the maximum weight a ball screw can handle. It determines the suitability of the ball screw for specific applications. A higher load capacity often allows for more robust machinery.

Speed ratings indicate how fast the ball screw can operate. This is important in applications requiring quick movement. Consider your machine's requirements when evaluating these metrics. A mismatch could lead to inefficiency.

Tips: Always match the load capacity with your machine's specs. A too high or too low capacity may cause issues. When checking speed ratings, remember that noise levels can increase at high speeds. This could affect nearby components. Test your setup before full-scale application. Adjustments may be necessary for optimal performance.

Material Choices and Their Impact on Durability and Cost

When searching for the best ball screw, material choices play a crucial role. Different materials significantly influence both durability and cost. Common options include stainless steel, carbon steel, and plastic composites. Each material has its advantages and trade-offs. Stainless steel offers excellent corrosion resistance but can be expensive. Carbon steel, on the other hand, is more affordable yet may rust if not properly coated.

The impact of material on performance should not be overlooked. For instance, a heavier material like steel can enhance stability but may add unnecessary weight to your application. Plastic composites can reduce weight but could wear out faster under high loads. It's essential to assess the specific requirements of your project before deciding. Consider how the environment affects material longevity. For some settings, a less durable option may lead to higher repairs or replacements.

Not all materials perform the same under stress. When pushed to their limits, some may fracture while others bend. This variability can lead to failures. It’s worthwhile to reflect on the long-term implications of your choice. Sometimes, opting for a less expensive material could yield higher overall costs through maintenance. Finding the right balance between cost and durability is an ongoing challenge.

2026 Best Ball Screw Material Choices and Their Impact on Durability and Cost

Top Manufacturers of Ball Screws in 2026: A Comparative Analysis

When exploring the best ball screw options in 2026, it's crucial to compare manufacturers. A thorough analysis reveals varying quality, performance, and pricing. Some manufacturers focus on precision. Others emphasize durability. Not all ball screws are created equal.

Tips: Always check the material used. Steel may offer strength but could lead to corrosion. Consider the application environment.

Performance factors are critical. Load capacity, speed, and accuracy must align with your needs. Some brands excel in high-speed applications, while others perform better under heavy loads.

Tips: Ask about the warranty. A longer warranty often indicates confidence in the product.

Look for user feedback and rating systems. Online reviews can highlight common issues. Some users report premature wear, which is a crucial aspect to consider before making a decision. Balancing cost, functionality, and reliability is essential.