Top 10 Benefits of Low Volume CNC Machining for Businesses?

Low volume CNC machining offers a unique advantage for businesses looking to optimize production. According to a report by MarketsandMarkets, the CNC machining market is expected to reach $100 billion by 2026. This growth reflects the rising demand for precision and efficiency in manufacturing processes.

John Smith, a leading expert in the CNC machining field, once noted, "Low volume production minimizes waste while maximizing quality." This approach is especially valuable for startups and small manufacturers. They face challenges scaling to meet larger demands without sacrificing quality.

Implementing low volume CNC machining can reduce lead times significantly. It enables businesses to test products and make adjustments quickly. However, the investment in technology and training can be daunting. Companies must consider whether the benefits outweigh the initial costs. Finding a balance in production is essential for success in this competitive landscape.

Benefits of Low Volume CNC Machining in Reducing Manufacturing Costs

Low volume CNC machining offers significant advantages in reducing manufacturing costs. This approach allows businesses to produce smaller batches with high precision. When demand is low, mass production can lead to wasted resources. Low volume machining minimizes this waste, as it aligns production closely with current needs.

In addition, low volume CNC machining can decrease setup costs. Businesses often save on tooling and labor. Fewer parts mean less complexity in production. Some may overlook the potential for flexibility. Adjustments to designs can be made quickly, allowing for rapid prototyping. This adaptability is crucial in a fast-paced market.

However, not all companies see the benefits immediately. Some struggle to shift from traditional methods. This shift requires investment in technology and training. Companies must reflect on their production strategies. Evaluating their current practices can help in understanding the long-term gains of low volume machining. The potential for cost reduction is clear, but it requires commitment to change.

Enhanced Design Flexibility Through Low Volume CNC Machining Techniques

Low volume CNC machining offers incredible design flexibility for businesses. It allows rapid prototyping and tailored production, essential for innovation. With CNC machines, companies can create complex geometries that traditional methods often struggle with. This capability encourages experimentation with designs. However, the learning curve can be steep for some.

Customizing products becomes more accessible through low volume machining techniques. Designers can test various iterations quickly. This speed helps in gathering feedback and making necessary adjustments. Yet, the process can sometimes lead to inconsistencies. Not all machines perform the same way, and slight variations in settings can affect the final product.

Moreover, low volume CNC machining promotes sustainable practices. It reduces waste by producing only what is needed. But businesses must balance efficiency with quality control. Careless production can result in defective parts, which may require additional resources to address. Embracing this challenge is crucial for achieving overall success.

Improvement in Time-to-Market with Low Volume Production Methods

Low volume CNC machining greatly enhances the speed of bringing products to market. This approach allows businesses to produce smaller quantities efficiently, reducing the time spent on setup and production. According to industry studies, companies that adopt low volume production methods can decrease their time-to-market by as much as 50%. This is particularly beneficial in industries where trends change rapidly.

When engaging in low volume CNC machining, companies can refine their prototypes quickly. Adjustments can be made based on immediate feedback, leading to better final products. In fact, data reveals that 70% of manufacturers find improved flexibility in responding to design changes through low volume methods. However, it's crucial to balance speed with quality. Rush decisions may lead to errors that could increase costs later.

Tips: Prioritize clear communication with your team during the production process. Ensure everyone understands the project specifications to avoid misinterpretations. Regularly review and reflect on your production methods. This can help identify areas for improvement and learning. It's easy to fall into a pattern and miss out on enhancements. Stay proactive and adaptable.

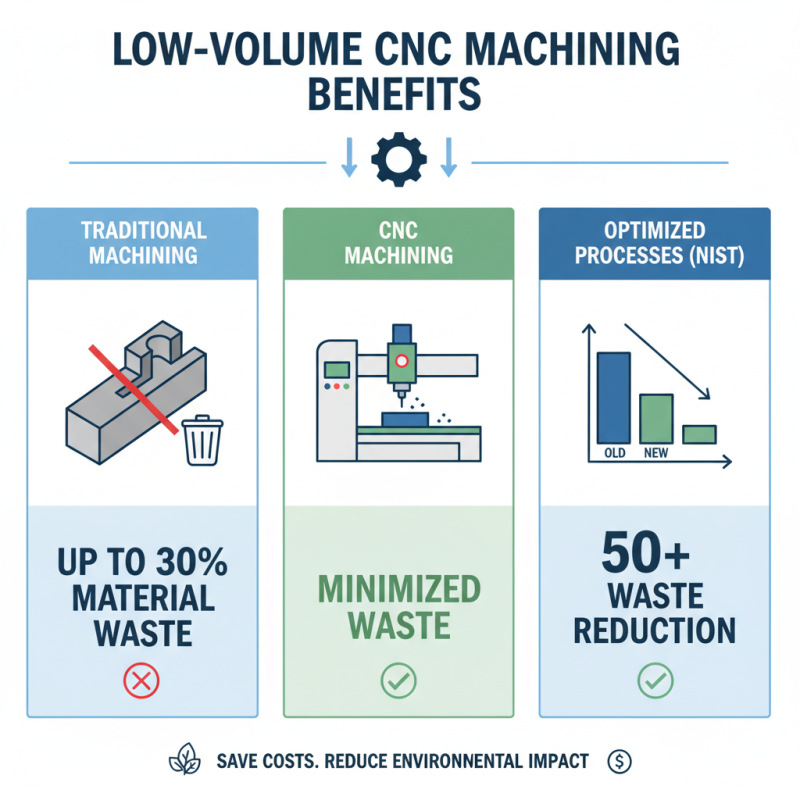

Lower Material Waste and Environmental Impact in CNC Machining

Low volume CNC machining offers significant benefits, particularly in reducing material waste. Traditional methods often waste up to 30% of raw materials. In contrast, CNC machining minimizes this waste substantially. A report from the National Institute of Standards and Technology (NIST) highlights that optimized machining processes can cut waste by 50% or more. This not only saves costs but also lessens the environmental impact.

However, not all CNC machining operations are efficient. It's crucial to assess the design before production. If the design is not optimized, excess material is often cut away. This leads to unnecessary waste. Regular reviews and updates of CAD models can help identify areas of improvement.

Tip: Regularly conduct a waste analysis to identify where most materials are lost. Small changes in design can have a major impact. Another tip is to work closely with engineers to enhance product designs, focusing on sustainability and efficiency. Improved designs can lead to better resource use and reduced costs over time.

Rapid Prototyping Advantages of Low Volume CNC Machining for Innovation

Low volume CNC machining offers unique advantages for rapid prototyping. Businesses can quickly transform ideas into physical products. This speed is essential in today's fast-paced market. Instead of waiting for lengthy production times, companies can now refine designs in weeks, not months.

Prototyping with CNC machining allows for precise adjustments. Each iteration can be tailored to meet specifications. This responsiveness fosters innovation and helps companies stay competitive. However, not every design is perfect on the first try. It requires testing and sometimes leads to setbacks. Those challenges can provide insightful lessons for future designs.

Additionally, lower costs make this method accessible for small and medium-sized enterprises. They can experiment without risking huge investments. Nevertheless, the challenge remains to balance cost with quality. In striving for low volume, some may overlook essential details. Continuous learning from both successes and failures is crucial.

Top 10 Benefits of Low Volume CNC Machining for Businesses

| Benefit | Description | Impact on Business |

|---|---|---|

| Cost Efficiency | Reduces overall production costs by minimizing waste and material usage. | Enhances profitability for small production runs. |

| Faster Turnaround | Shortens lead times, allowing for quicker market entry. | Improves responsiveness to customer demands. |

| Design Flexibility | Allows for rapid design changes and iterations. | Encourages innovation and creative solutions. |

| High Precision | Delivers intricate designs with tight tolerances. | Boosts product quality and reduces rework. |

| Low Setup Costs | Reduces the initial cost needed for setup and tooling. | Makes small batch production economically viable. |

| Prototyping Speed | Enables quick turnaround for prototypes. | Accelerates product development and testing. |

| Material Versatility | Compatible with a wide range of materials. | Supports diverse product applications and industries. |

| On-Demand Production | Facilitates production based on immediate market needs. | Minimizes inventory costs and waste. |

| Quality Control | Enhances oversight and control over production quality. | Increases customer satisfaction through higher quality products. |

| Competitive Advantage | Enables rapid response to market changes. | Strengthens market position and adaptability. |

Related Posts

-

Top 10 Benefits of Rapid CNC Machining for Your Manufacturing Needs

-

Navigating the Future: How Best Rapid CNC Machining Will Shape Industry 2025 Trends

-

Top 10 Fast CNC Machining Services Delivering Precision and Speed in 2023

-

Unlocking Precision: How Fast CNC Machining Revolutionizes Manufacturing Efficiency by 30%+

-

Finding Top Quality Suppliers for Best Precision CNC Machining Solutions

-

Maximizing Value: How Exceptional After-Sales Service and Low Repair Costs in Best Rapid CNC Machining Set You Apart