Top Advantages of Precision CNC Machining for Modern Manufacturing?

Precision CNC machining is revolutionizing modern manufacturing. According to a recent report by the International Federation of Robotics, CNC machinery has increased productivity by over 30% across various sectors. Experts estimate that precision CNC machining reduces waste by up to 50%, which is critical in today's competitive landscape.

Dr. Emily Carter, a leading expert in manufacturing technology, states, "Precision CNC machining is not just an option; it's a necessity for businesses striving for efficiency." Companies see clear benefits, such as improved accuracy and faster production times. However, many still confront challenges, including high initial costs and the steep learning curve for operators.

Despite these hurdles, organizations must weigh the long-term advantages. Precision CNC machining is not perfect; it requires thorough understanding and adaptation. Manufacturers must continuously reflect on processes to fully harness its potential. The path is not always straightforward, but the rewards can redefine success in manufacturing.

Understanding Precision CNC Machining in Modern Manufacturing

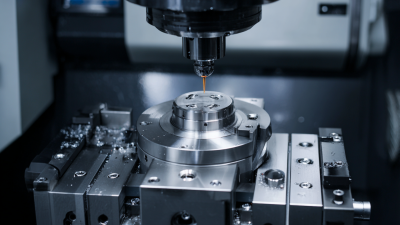

Precision CNC machining has become vital in modern manufacturing. It emphasizes accuracy and repeatability. According to a recent industry report, CNC machining can achieve tolerances as tight as ±0.001 inches. This precision supports the production of complex components in various sectors, including aerospace, automotive, and medical devices.

However, the method isn't without its challenges. The setup time can be significant. Each new part requires calibration of the CNC machines, which can slow down initial production. Industry analysis reveals that effective programming and simulation can mitigate this, yet many manufacturers still struggle with optimization.

Additionally, while CNC machining minimizes waste by maximizing material use, it can still lead to excess scrap in poorly planned processes. Data indicates that up to 15% of material can be lost in inefficient setups. Despite this, the accuracy and efficiency often outweigh these issues. Precision CNC machining drives innovation and effectiveness in modern manufacturing, even as companies continue to refine their approaches.

Key Benefits of Precision in CNC Machining Processes

Precision CNC machining has transformed modern manufacturing by offering key benefits that enhance production efficiency and accuracy. One of the most significant advantages is the high level of precision in the manufacturing process. This ensures that each component is crafted to exact specifications, reducing the need for rework or adjustments later. Such accuracy is crucial in industries like aerospace and automotive, where even the smallest deviation can lead to costly failures.

Another important benefit is the ability to produce complex geometries easily. Traditional machining methods often struggle with intricate designs, while CNC machines can handle them with ease. This capability opens the door for innovative product designs. Designers can push boundaries without being limited by production constraints. However, this technology isn't perfect. A steep learning curve exists for operators, and poor programming can lead to errors.

Cost efficiency is another key advantage. Despite higher initial investments, CNC machining reduces long-term costs. This happens through minimized material waste and streamlined production timelines. Nevertheless, businesses must carefully evaluate whether the upfront costs align with their operational budgets. Overall, the precision and efficiency of CNC machining are significant in advancing manufacturing, even though challenges remain.

Top Advantages of Precision CNC Machining for Modern Manufacturing

| Advantage | Description | Impact on Manufacturing |

|---|---|---|

| High Precision | Allows for tight tolerances in manufacturing, ensuring parts fit together perfectly. | Reduces waste and rework costs, enhancing overall product quality. |

| Efficiency | Rapid production speeds with minimal human error. | Increases output, leading to better profitability and shorter lead times. |

| Complex Geometries | Capable of producing intricate designs that are difficult to achieve with traditional methods. | Enables innovation in product design and engineering. |

| Material Versatility | Compatible with a wide range of materials including metals, plastics, and composites. | Expands possibilities for product development across various industries. |

| Cost-Effectiveness | Reduces labor costs and minimizes material wastage. | Enhances the overall efficiency and profitability of manufacturing processes. |

Cost Efficiency through High-Volume Production in CNC Machining

Precision CNC machining has transformed the landscape of modern manufacturing. One major benefit is its cost efficiency in high-volume production. Manufacturers can create numerous parts quickly. This approach significantly reduces labor costs and production time. For industries producing large quantities, CNC machining is often the preferred choice.

However, challenges exist. High initial setup costs can deter smaller manufacturers. Additionally, if not managed properly, waste can accumulate during the machining process. This can lead to increased costs, negating some of the initial savings. Despite these hurdles, the long-term savings usually make CNC machining worthwhile for many.

Quality control is another aspect to examine. Maintaining precision over long runs is crucial but can be tricky. Small errors in the setup can lead to larger issues down the line. Regular inspections are necessary but require additional time and resources. Balancing efficiency with quality is an ongoing challenge for manufacturers.

Enhanced Design Flexibility and Customization in CNC Machining

Precision CNC machining offers remarkable design flexibility that empowers modern manufacturing. In 2022, the global CNC machining market was valued at approximately $70 billion, and it is expected to grow rapidly. This growth stems from the increasing need for customization in various industries, including aerospace and automotive. Traditional methods often struggle to meet unique design specifications, while CNC machining allows for intricate shapes and dimensions with high precision.

Design customization is further enhanced by advanced software integration. Engineers can create complex geometries that were once impossible to achieve. This flexibility speeds up the prototyping phase, providing manufacturers the ability to test and iterate designs quickly. However, the reliance on software may introduce errors if not managed carefully. It's crucial to balance innovation with rigorous quality checks to prevent costly mistakes in production.

Customization extends beyond mere shapes. It includes material selection, surface finishes, and tolerances. Reports indicate that about 75% of manufacturers are investing in CNC machining capabilities to stay competitive. However, adapting to new technologies can be challenging. Companies must continuously train their workforce to handle sophisticated CNC systems. As manufacturing demands evolve, the need for scalable and flexible solutions becomes paramount. Embracing this complexity might lead companies to rethink their traditional production strategies.

Improved Quality Control and Consistency in Manufactured Products

Precision CNC machining plays a vital role in modern manufacturing. This technology enhances quality control significantly. With precise computer numerical controls, manufacturers achieve consistent results in each batch. This means that parts produced today will match the specifications of those made last week. It leads to fewer errors and a more reliable supply chain.

However, the process is not infallible. Even with advanced machinery, human oversight is necessary. Operators must regularly check for calibration and wear. A small oversight can lead to defects in critical components. It's essential to maintain a balance between automated precision and human intervention. This reflection is crucial for continuous improvement in quality control.

Moreover, the ability to detect inconsistencies early can save time and resources. Regular audits help identify potential issues before they escalate. With precision machining, defects are often visible in the early stages. Encouraging teams to communicate about quality concerns can foster a culture of excellence. This proactive approach to quality ensures that even in a high-tech environment, there is room for reflection and growth.

Related Posts

-

7 Best Practices for Precision CNC Machining: Achieving 99.9% Accuracy in Manufacturing

-

Top 5 Precision CNC Machining Techniques for Optimal Results

-

Finding Top Quality Suppliers for Best Precision CNC Machining Solutions

-

Top 10 Benefits of Rapid CNC Machining for Your Manufacturing Needs

-

Top 10 Fast CNC Machining Services Delivering Precision and Speed in 2023

-

Unlocking Precision: How Fast CNC Machining Revolutionizes Manufacturing Efficiency by 30%+